Compound sensor for measuring appearance of nanometer by using holographic laser

A technology for measuring sensors and holographic lasers, which is applied to measuring devices, instruments, and optical devices, etc., can solve the problems of being unable to meet the needs of fast and accurate measurement of nanometer appearance, and the measurement range is small, and achieve the effect of simple structure and low price.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

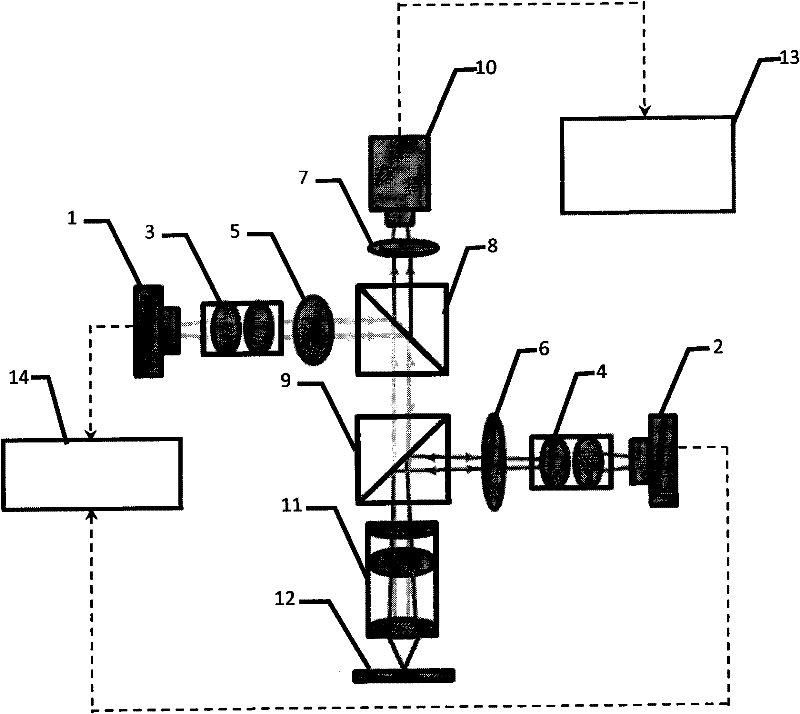

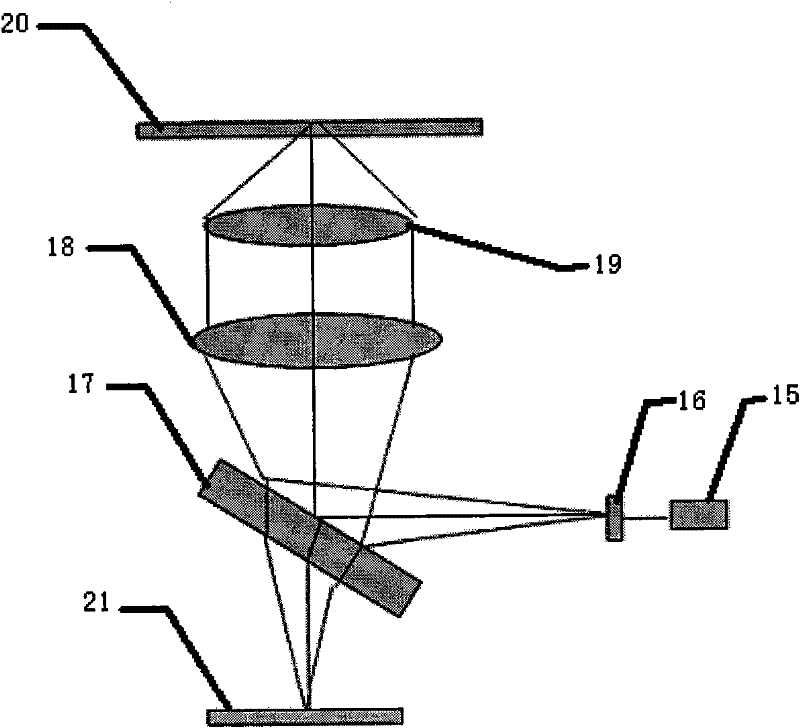

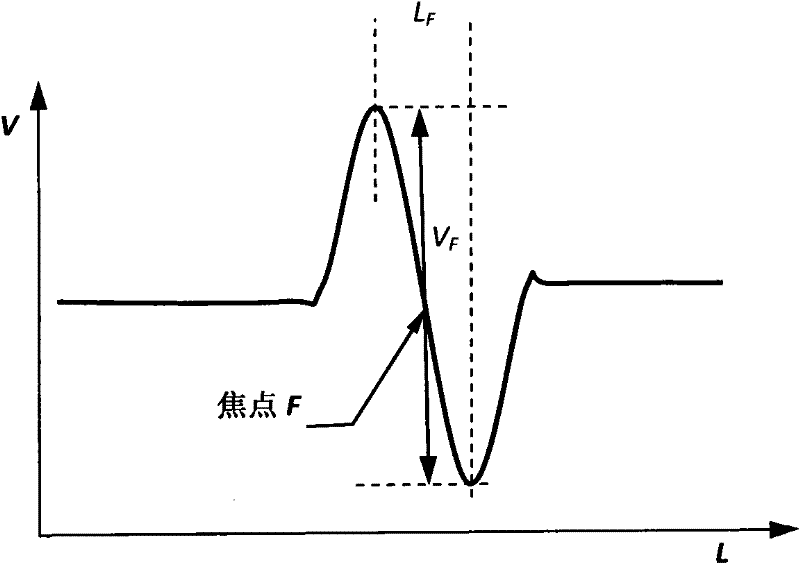

[0028] A composite holographic laser nanometer shape measurement sensor, such as figure 1 As shown, it consists of holographic laser reading head 1, holographic laser reading head 2, optical components, micro-optical objective lens, measurement template, electrical measurement system, CCD camera and monitoring system; the optical components include optical lens group 1, optical lens Group 2, adjusting lens 1, adjusting lens 2, adjusting lens 3, beam splitter 1 and beam splitter 2;

[0029] The light emitted by the holographic laser reading head 1 becomes parallel light after passing through the optical lens group 1 and the adjusting lens 1, and then focuses on the measurement sample after passing through the beam splitter 1, the beam splitter 2 and the micro-optical objective lens; the holographic laser reading head 2 emits The light becomes parallel light after passing through the optical lens group 2 and the adjusting lens 2, and then focuses to the measurement sample plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com