Square silicon wafer compatibility rotating tray and silicon wafer cleaning device

A rotating tray, compatible technology, used in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as easy damage to the surface of silicon wafers and easy accumulation of chemical liquids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

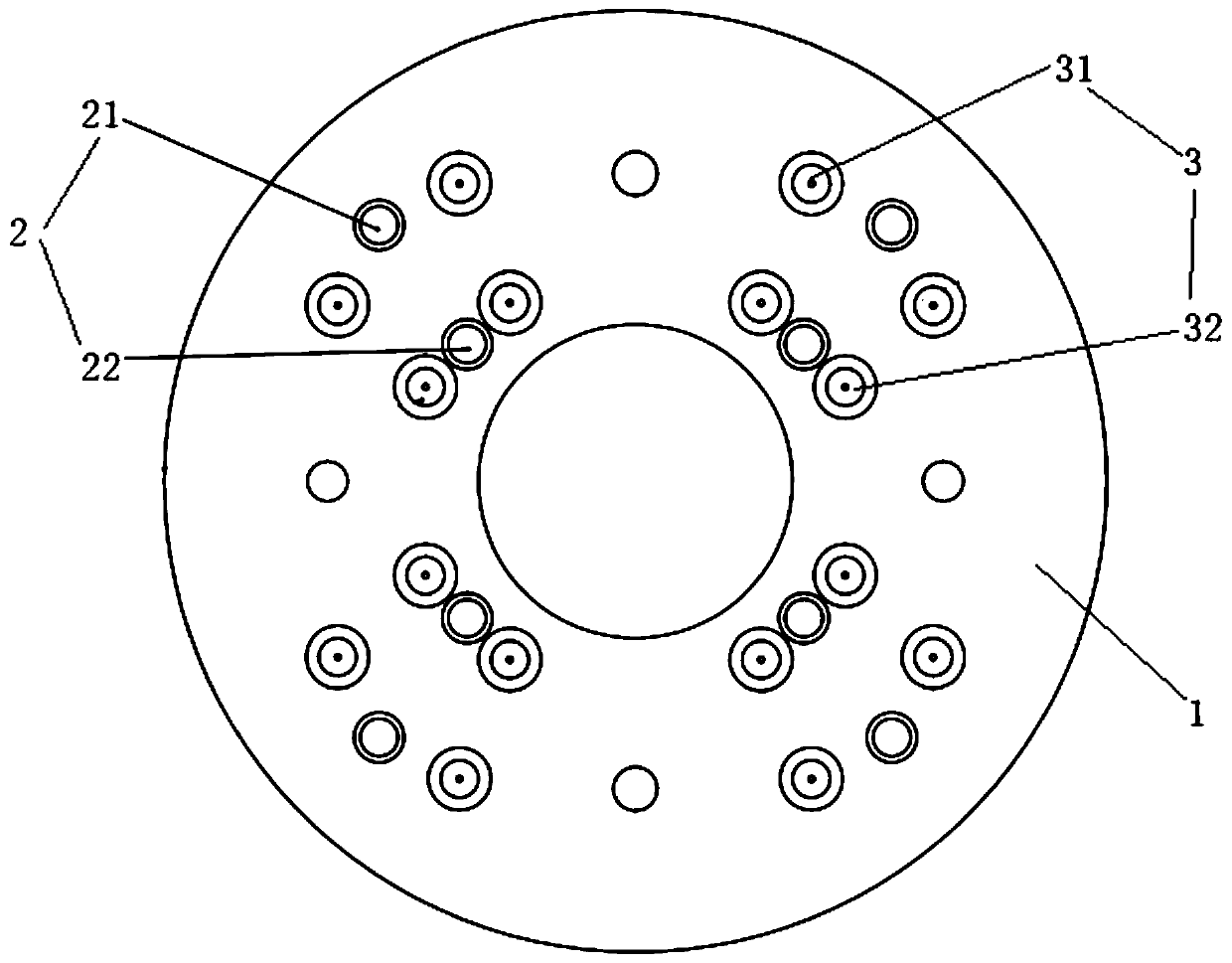

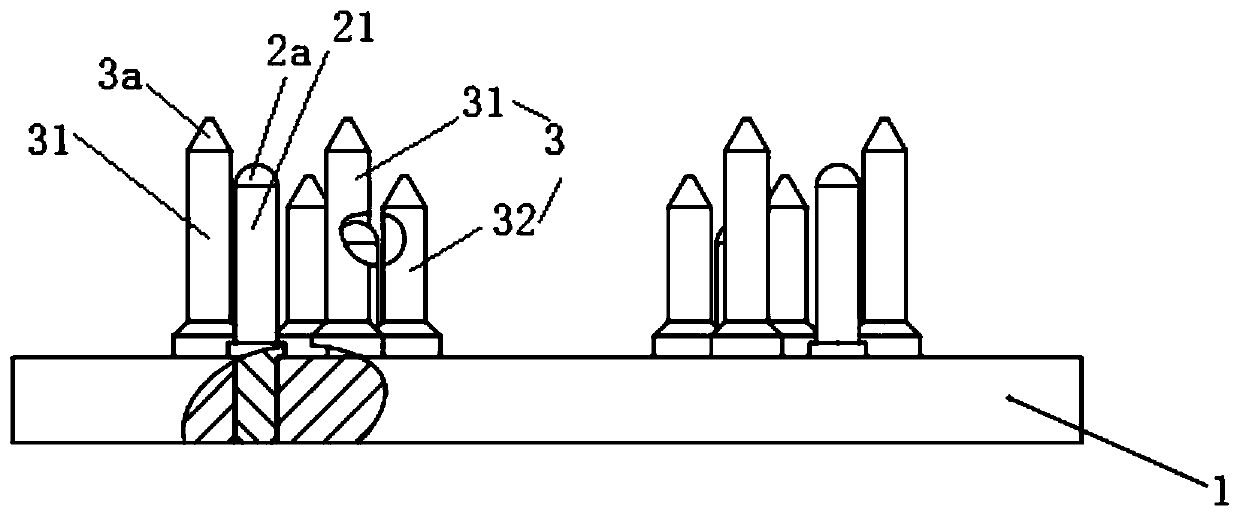

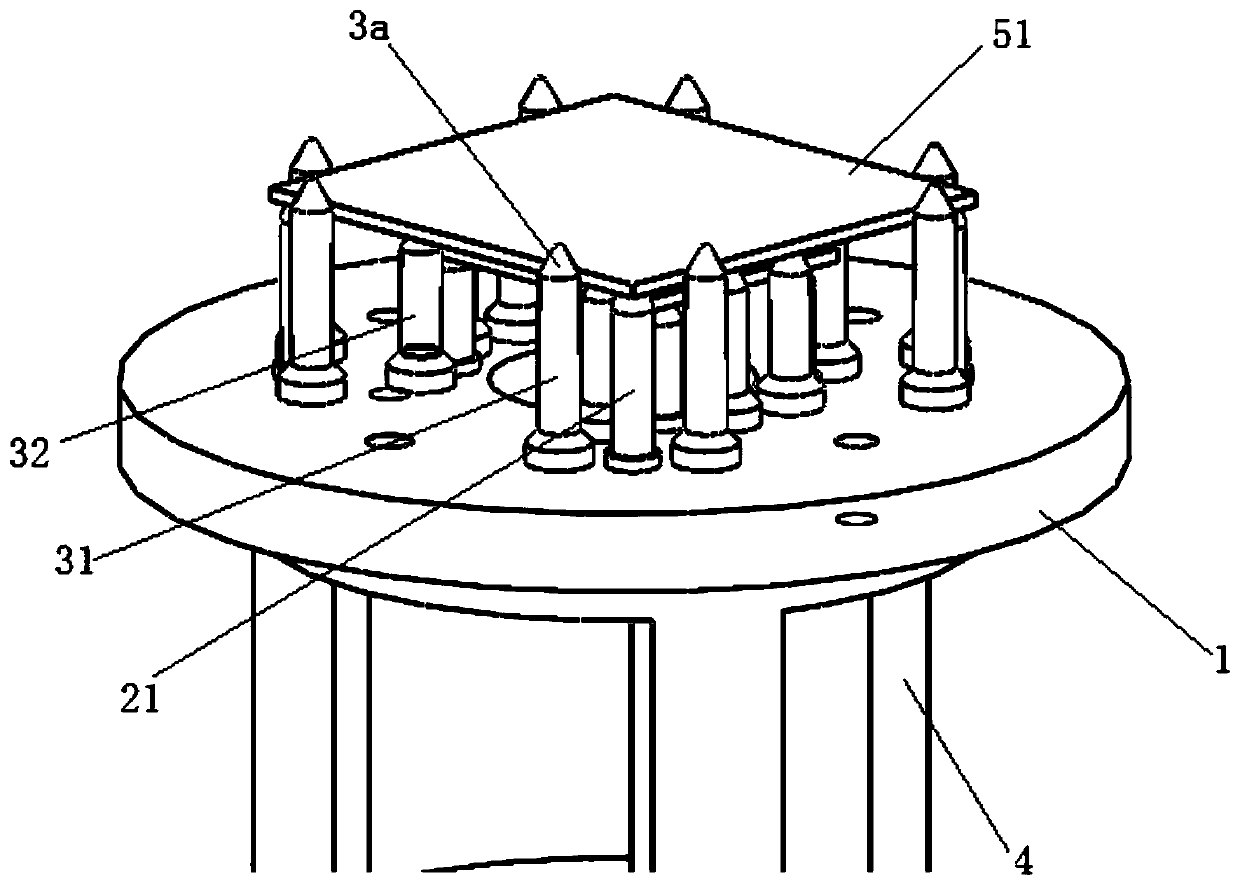

[0038] see Figure 1 to Figure 6 As shown, this embodiment provides a square silicon wafer compatible rotating tray for supporting the square silicon wafer 5 . Specifically, the square silicon wafer compatibility rotary tray includes a bottom support chuck 1, and at least one wafer support mechanism is arranged on the bottom support chuck 1. The silicon wafer support mechanism includes a support column group and a stop column group, and the support column group and the stop column The groups are respectively fixed on the bottom supporting chuck 1.

[0039] The supporting pillar group comprises four supporting pillars 2, and four supporting pillars 2 are respectively arranged corresponding to the quarter vertices of the square silicon wafer 5, and the supporting pillars 2 and the vertices of the square silicon wafer 5 are set in one-to-one correspondence; each supporting pillar 2 is close to The apex of the corresponding square silicon wafer is arranged on the inner edge of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com