Semiautomatic infusion preparation apparatus for neonatal parenteral nutrient admixture

A semi-automated, nutrient solution technology, applied in the field of machinery, can solve the problems of newborn intravenous nutrient solution that cannot be sealed and proportioned, manpower and time-consuming, and achieve the effects of saving manpower and time, accurate dosage, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

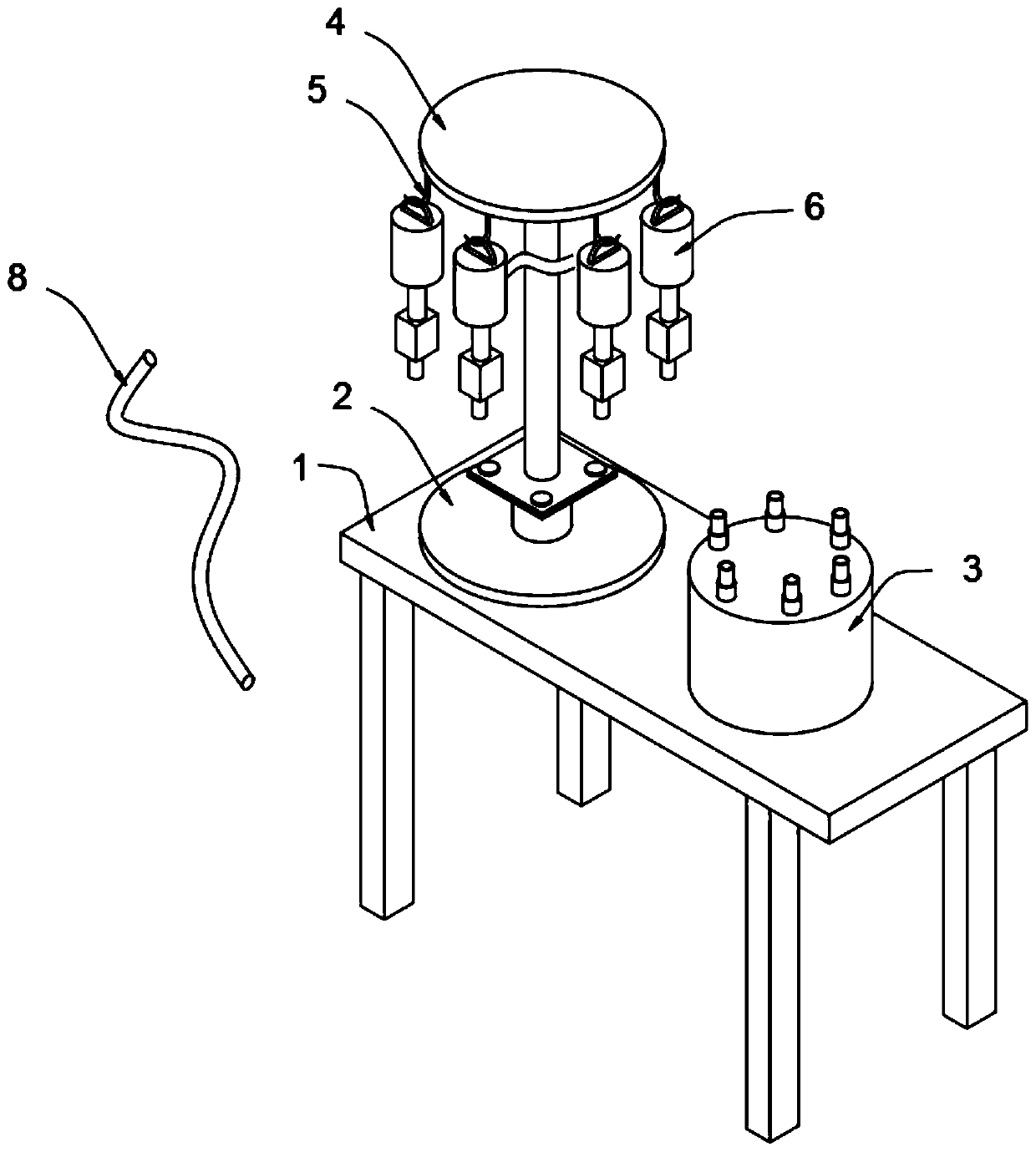

[0026] A semi-automatic liquid dispenser for intravenous nutrient solution for newborns, such as figure 1 and figure 2 As shown, including the workbench 1, the top side of the workbench 1 is equipped with a rotation mechanism 2, the side of the top surface of the workbench 1 away from the rotation mechanism 2 is installed with a liquid distribution tank 3, and the top of the rotation mechanism 2 is installed with a suspension plate 4. A number of evenly equidistant hooks 5 are installed on the edge of the bottom surface of the suspension plate 4, and each hook 5 is equipped with a raw material holding device 6;

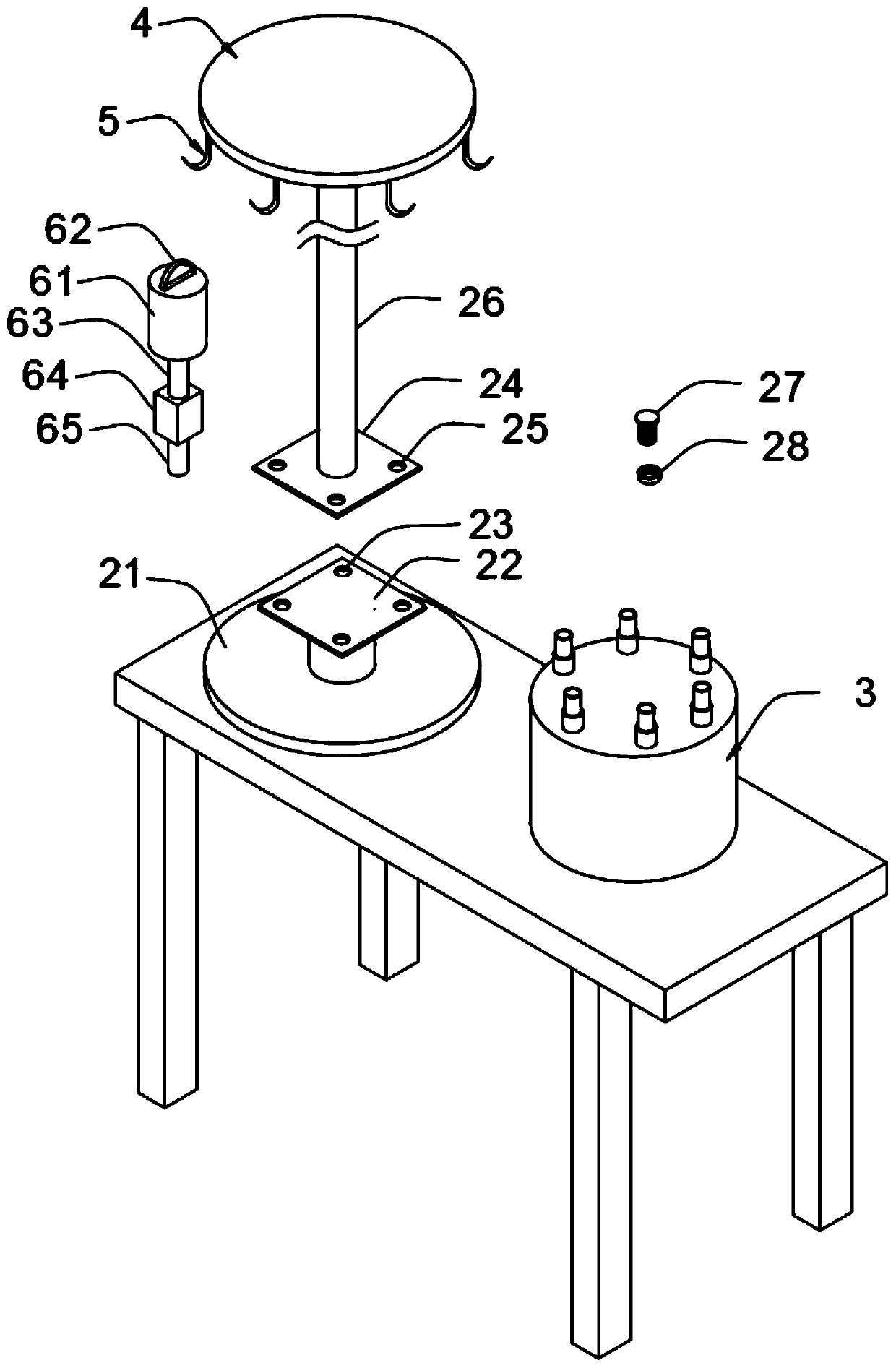

[0027] Specifically, the raw material storage device 6 includes a raw material storage box 61, the top of the raw material storage box 61 is connected with a hanging ring 62, and the bottom of the raw material storage box 61 is connected with a feeding tube 63, and the feeding tube 63 is far away from the raw material storage box. An infusion pump 64 is connected to...

Embodiment 2

[0031] In order to solve the problem that the raw material storage box 61 is not easy to remove and place when in use, the inventors improved the rotating mechanism 2 in Embodiment 1. As a preferred technical solution of Embodiment 1, the rotating mechanism 2 includes a fixed The chassis 21, the center of the fixed chassis 21 is provided with a rotating chassis 22, the four corners of the rotating chassis 22 are provided with mounting holes 23, the top of the rotating chassis 22 is connected with a connecting plate 24, and the four corners of the connecting plate 24 Both are provided with connection holes 25 , and the center of the top surface of the connection plate 24 is connected with a support shaft 26 .

[0032] Further, the tops of the connection plate 24, the support shaft 26 and the suspension plate 4 are integrally formed, and the suspension plate 4, the support shaft 26 and the connection plate 24 are coaxially arranged.

[0033] Specifically, the size of the rotatin...

Embodiment 3

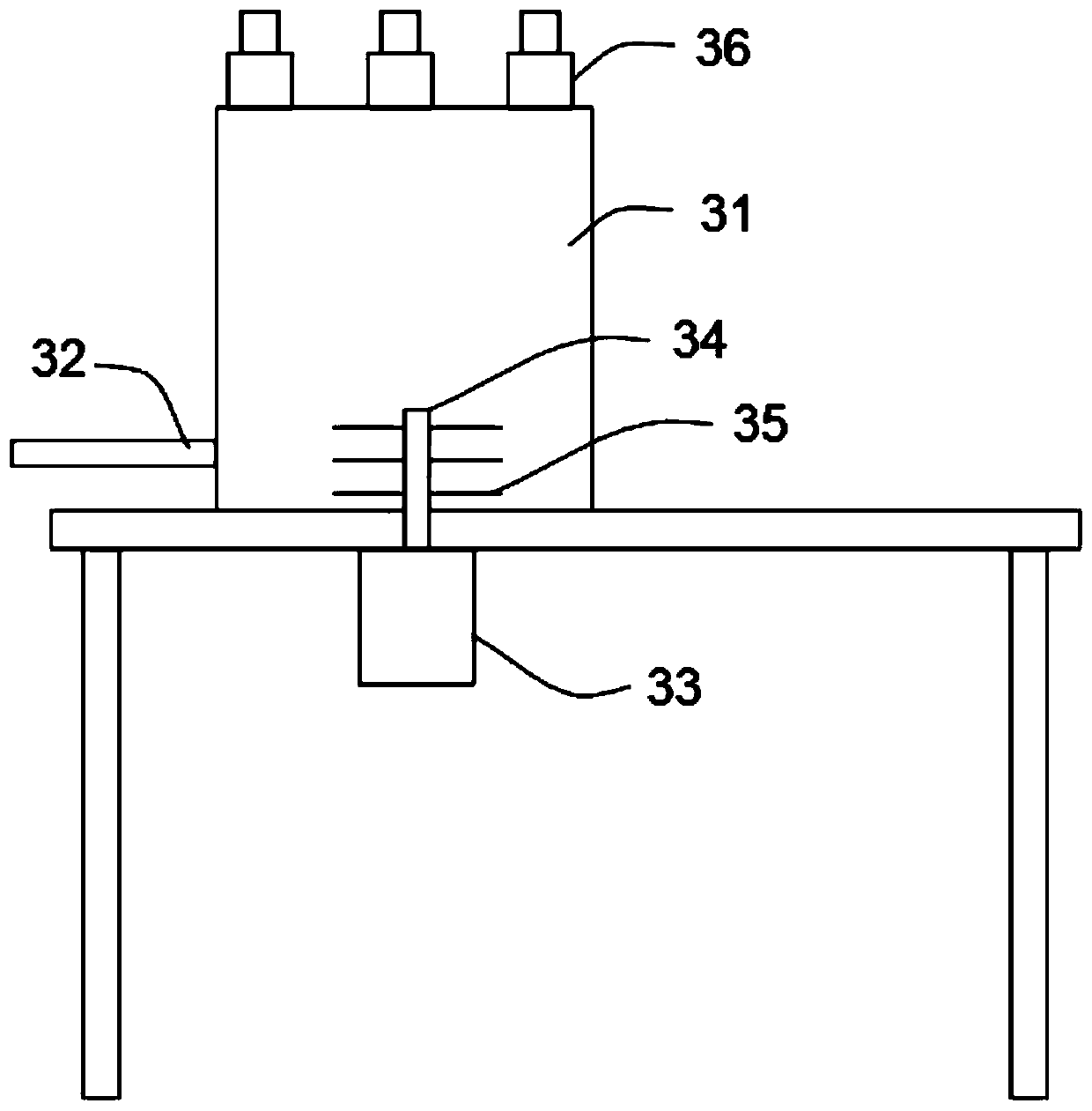

[0037] In order to solve the problem that the liquid distribution tank 3 is inconvenient to stir during use, the inventor made improvements to the liquid distribution tank 3 in Embodiment 1, as a preferred technical solution of Embodiment 1, such as image 3 As shown, the liquid distribution box 3 includes a box body 31, the bottom of the circumferential surface of the box body 31 is connected with a liquid discharge pipe 32, and the bottom of the workbench 1 is equipped with a stirring motor 33, and the stirring motor 33 is arranged directly below the box body 31. The rotor of the stirring motor 33 is connected with a stirring shaft 34, the stirring shaft 34 passes through the inner wall of the workbench 1 and extends to the inside of the casing 31, and the stirring blade 35 is arranged on the circumferential surface of the stirring shaft 34 inside the casing 31. The top of the body 31 is equipped with a number of second connectors 36 arranged evenly and equidistantly.

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com