Glass explosion-proof performance detecting device and method

A detection equipment and glass technology, which is applied in the field of glass explosion-proof performance detection equipment, can solve the problems of limited observation with the naked eye, high labor costs, and high burden on enterprises, and achieve the effects of convenient and fast detection, reduced detection intensity, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

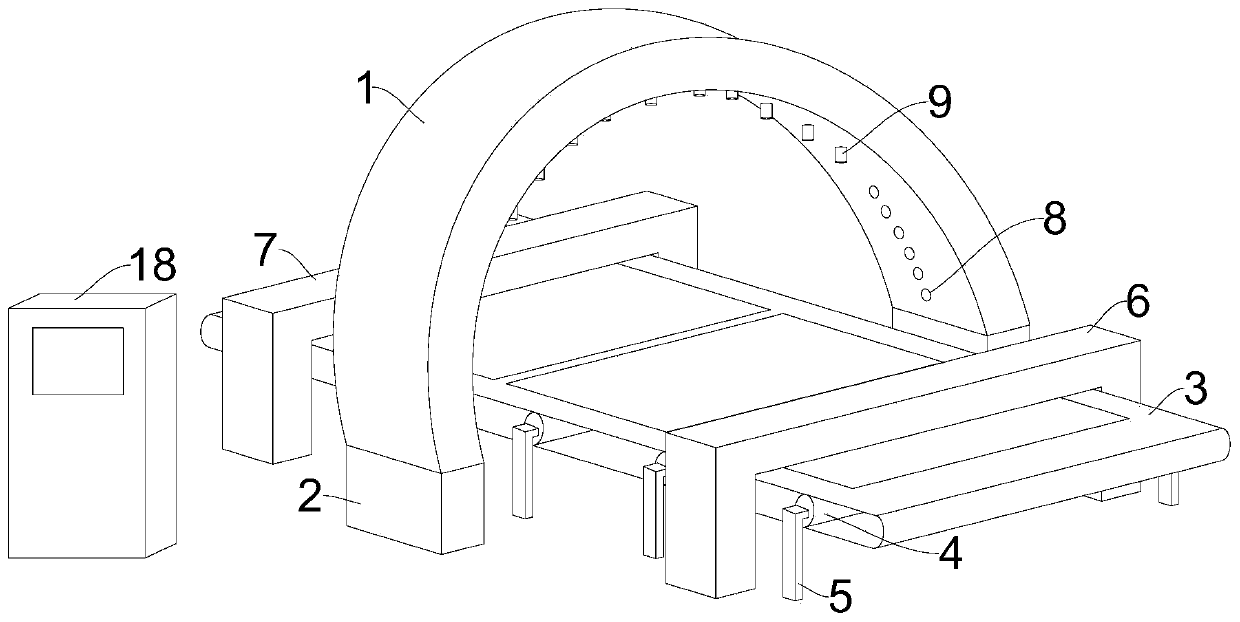

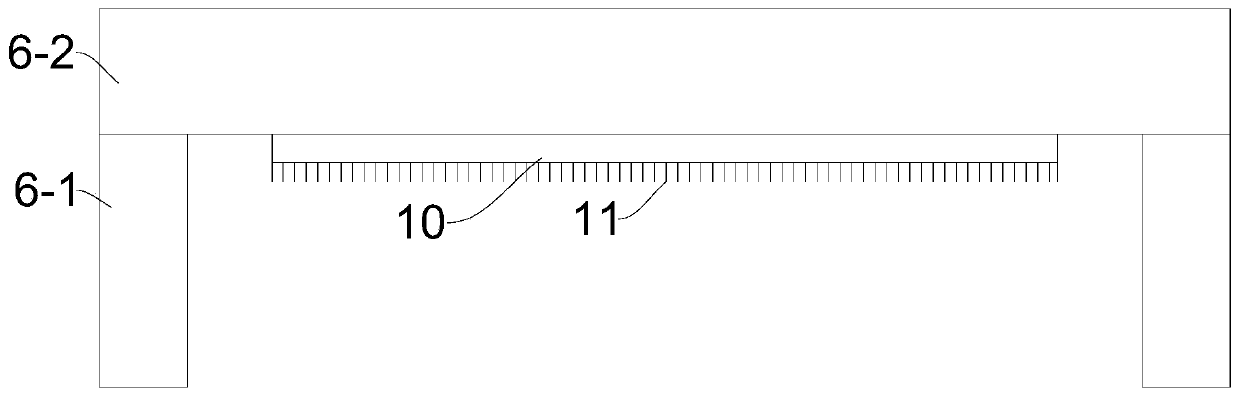

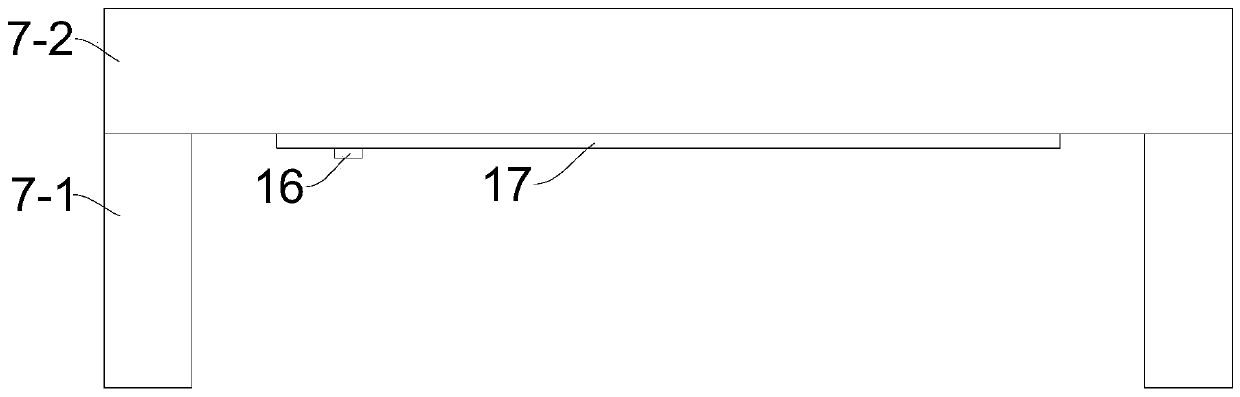

[0036] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, a glass explosion-proof performance testing equipment includes a detection frame 1, a conveying device and a control device 18, the detection frame 1 is set up vertically above the conveying device, the detection frame 1 is an arc door arch type, and the detection frame 1 is stainless steel material, the conveying device is used to convey tempered glass, the tempered glass is placed on the conveying device, and the conveying device passes through the detection frame 1, so that the tempered glass passes through the detection frame 1, and the bottom ends of both sides of the detection frame 1 are provided for fixing The fixed seat 2 on the ground, the fixed seat 2 is poured on the ground, the bottom ends of both sides of the detection frame 1 are fixedly connected to the fixed seat 2 by bolts, and the bottom end of the detection frame 1 is provided with an image collector 9 facing the conveying device The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com