Clinker for producing alumina by series method and process thereof

A technology of alumina and tandem method, which is applied in the production of alumina clinker and its technology field by tandem method, which can solve the problems of clinker kiln firing belt ringing and clinker kiln operation difficulties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

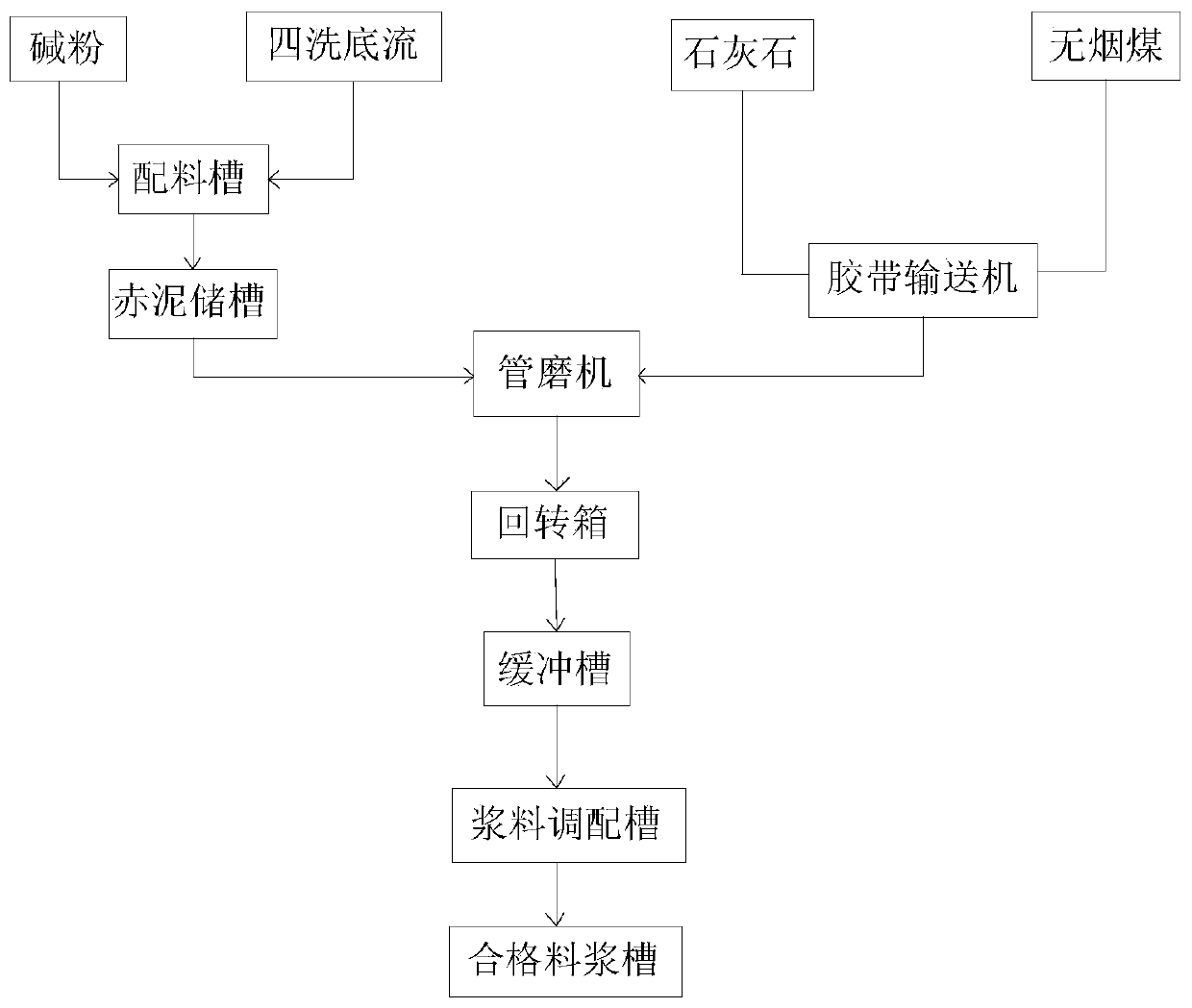

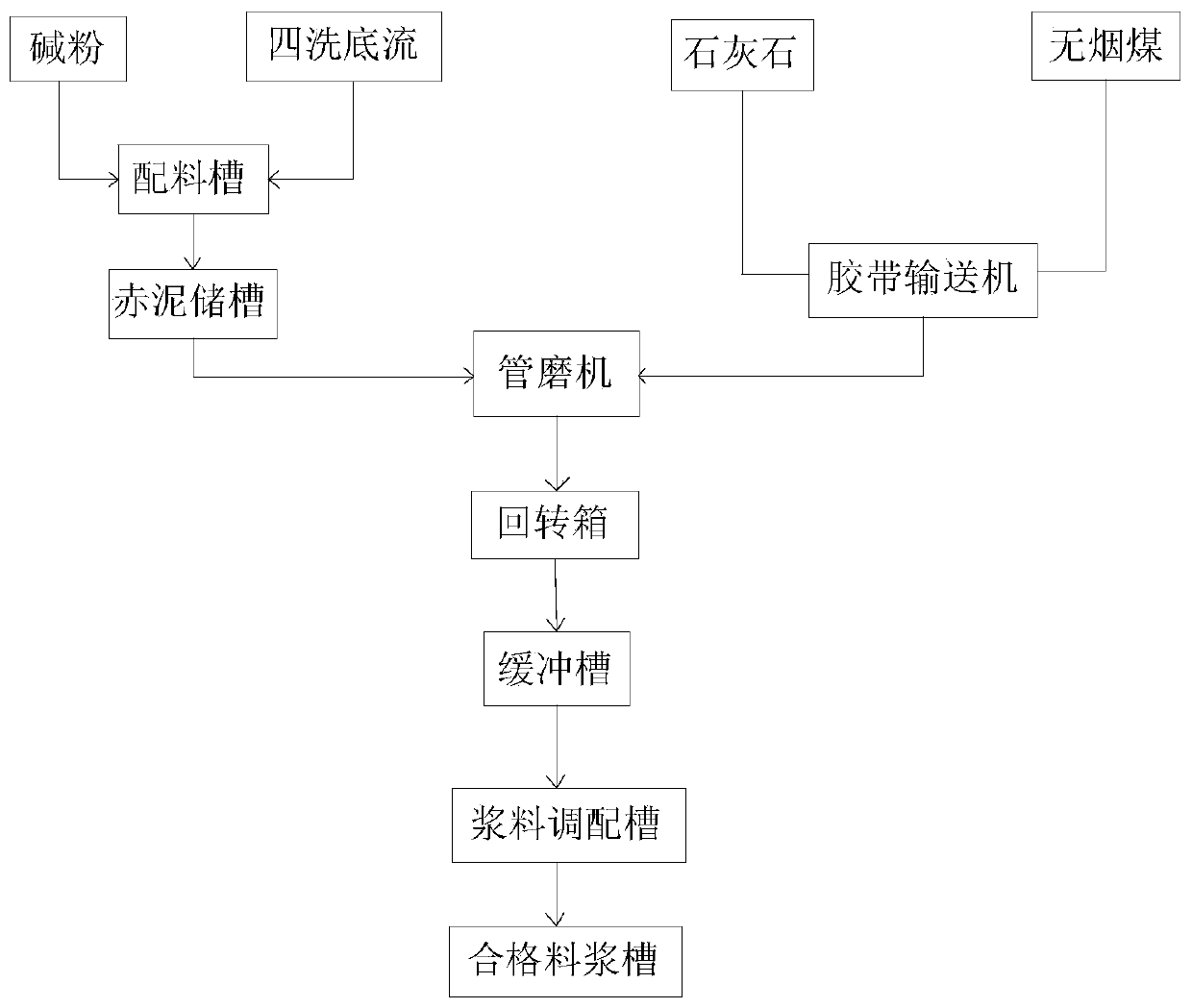

Method used

Image

Examples

Embodiment 1

[0030] This embodiment provides a clinker for producing alumina by a series method, which includes: alkali powder, Bayer process red mud, limestone and anthracite.

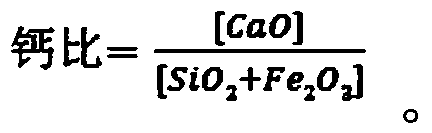

[0031] Among them, the alkali ratio of clinker is 1.04, and the calcium ratio is 1.08; wherein, the alkali ratio refers to the molar ratio of sodium oxide to aluminum oxide, and the calcium ratio refers to the molar ratio of calcium oxide to the sum of silicon oxide and iron oxide. And the iron content in the clinker is 16%.

Embodiment 2

[0033] This embodiment provides a kind of clinker for producing alumina by a series method, which is roughly the same as the clinker provided in Example 1, the difference is that the parameters are different, and the difference is as follows:

[0034] The alkali ratio of the clinker is 1.00, and the calcium ratio is 1.02; wherein, the alkali ratio refers to the molar ratio of sodium oxide to aluminum oxide, and the calcium ratio refers to the molar ratio of calcium oxide to the sum of silicon oxide and iron oxide. And the iron content in the clinker is 15%.

Embodiment 3

[0036] This embodiment provides a kind of clinker for producing alumina by a series method, which is roughly the same as the clinker provided in Examples 1-2, the difference lies in the different parameters, and the difference is as follows:

[0037] The alkali ratio of the clinker is 1.08, and the calcium ratio is 1.14; wherein, the alkali ratio refers to the molar ratio of sodium oxide to aluminum oxide, and the calcium ratio refers to the molar ratio of calcium oxide to the sum of silicon oxide and iron oxide. And the iron content in the clinker is 15%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com