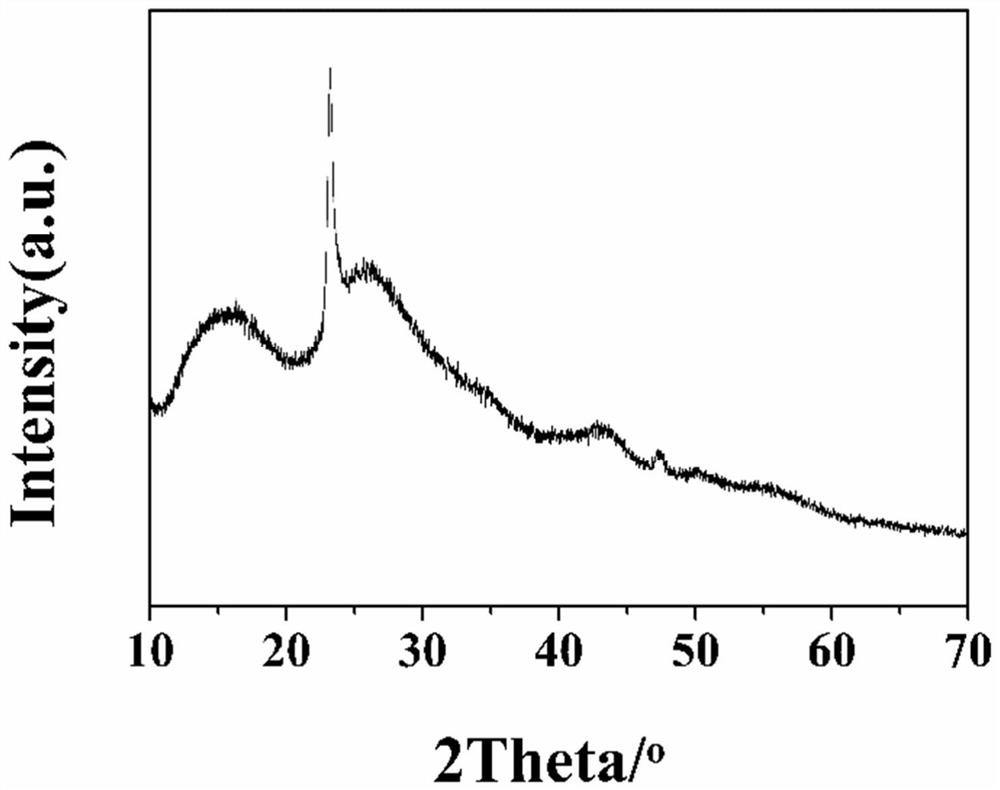

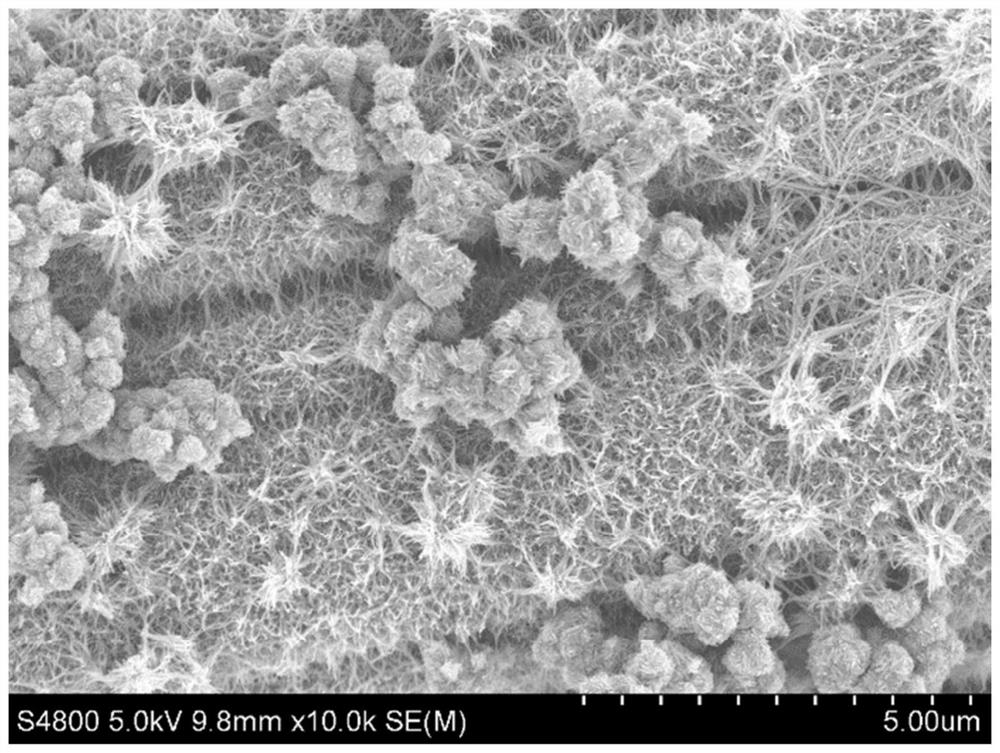

In situ growth on the surface of a carbon cloth 18 o 49 Preparation method of self-supporting electrode material

A technology of self-supporting electrodes and in-situ growth, applied in electrodes, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve unfavorable large-scale production, mismatch of pH range auxiliary equipment, reduce The overall performance of the electrolytic cell and other issues have been achieved to achieve the effects of short preparation cycle, low cost and mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1) First immerse the carbon cloth with a length of 1 cm and a width of 4 cm in acetone for 30 minutes, then place the treated carbon in a 3 mol / L HCl solution for 30 minutes, then use pure water for 30 minutes, and finally Place it in absolute ethanol for 30 minutes of ultrasonic treatment, and finally continue to rinse with absolute ethanol for 5 times;

[0029] 2) will analyze pure tungsten source WCl 6 Add a volume ratio of absolute ethanol: isopropanol: n-butanol = 1:0.5:0.5 mixed alcohol to make a 0.05mol / L solution A;

[0030] 3) Add analytically pure ethylenediamine and citric acid to solution A according to the ratio of ethylenediamine, citric acid and tungsten source at a ratio of 0.05:0.05:1, stir magnetically for 30 minutes, and sonicate for 10 minutes to obtain solution B;

[0031] 4) Pour solution B into a polytetrafluoroethylene-lined autoclave at a volume filling ratio of 40%, and put the treated carbon cloth into the polytetrafluoroethylene reactor cont...

Embodiment 2

[0037] 1) First immerse the carbon cloth with a length of 1 cm and a width of 7 cm in acetone for 30 minutes, then place the treated carbon in a 4 mol / L HCl solution for 20 minutes, then use pure water for 20 minutes, and finally Place it in absolute ethanol for ultrasonic treatment for 20 minutes, and finally rinse with absolute ethanol for 5 times;

[0038] 2) Will analyze pure tungsten source W(CO) 6 Add a volume ratio of ethanol: isopropanol: n-butanol = 1:0.3:0.6 mixed alcohol to make a 0.1mol / L solution A;

[0039] 3) Add analytically pure ethylenediamine and citric acid into solution A according to the ratio of ethylenediamine, citric acid and tungsten source in the amount of 0.06:1:1, magnetically stir for 30 minutes, and ultrasonically treat for 5 minutes to obtain solution B;

[0040] 4) Pour solution B into a polytetrafluoroethylene-lined autoclave at a volume filling ratio of 50%, and put the treated carbon cloth into the polytetrafluoroethylene reactor containing s...

Embodiment 3

[0045] 1) First immerse the carbon cloth with a length of 1 cm and a width of 6 cm in acetone for 30 minutes, then place the treated carbon in a 3 mol / L HCl solution for 30 minutes, then use pure water for 30 minutes, and finally Place it in absolute ethanol for 30 minutes of ultrasonic treatment, and finally continue to rinse with absolute ethanol for 5 times;

[0046] 2) will analyze pure tungsten source W(C 2 h 5 O) 6 Add a volume ratio of absolute ethanol: isopropanol: n-butanol = 1:0.2:0.8 mixed alcohol to make a 0.05mol / L solution A;

[0047] 3) Add analytically pure ethylenediamine and citric acid to solution A according to the ratio of ethylenediamine, citric acid and tungsten source in the amount of 0.1:0.1:1, stir magnetically for 50 minutes, and sonicate for 8 minutes to obtain solution B;

[0048] 4) Pour solution B into a polytetrafluoroethylene-lined autoclave with a volume filling ratio of 60%, and put the treated carbon cloth into the polytetrafluoroethylene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com