Paper mold intelligent automatic forming process

An automatic forming and intelligent technology, applied in textiles and papermaking, etc., can solve the problems that restrict the development of the paper mold industry, cannot effectively solve the problem of pulp precipitation, and cannot further improve production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

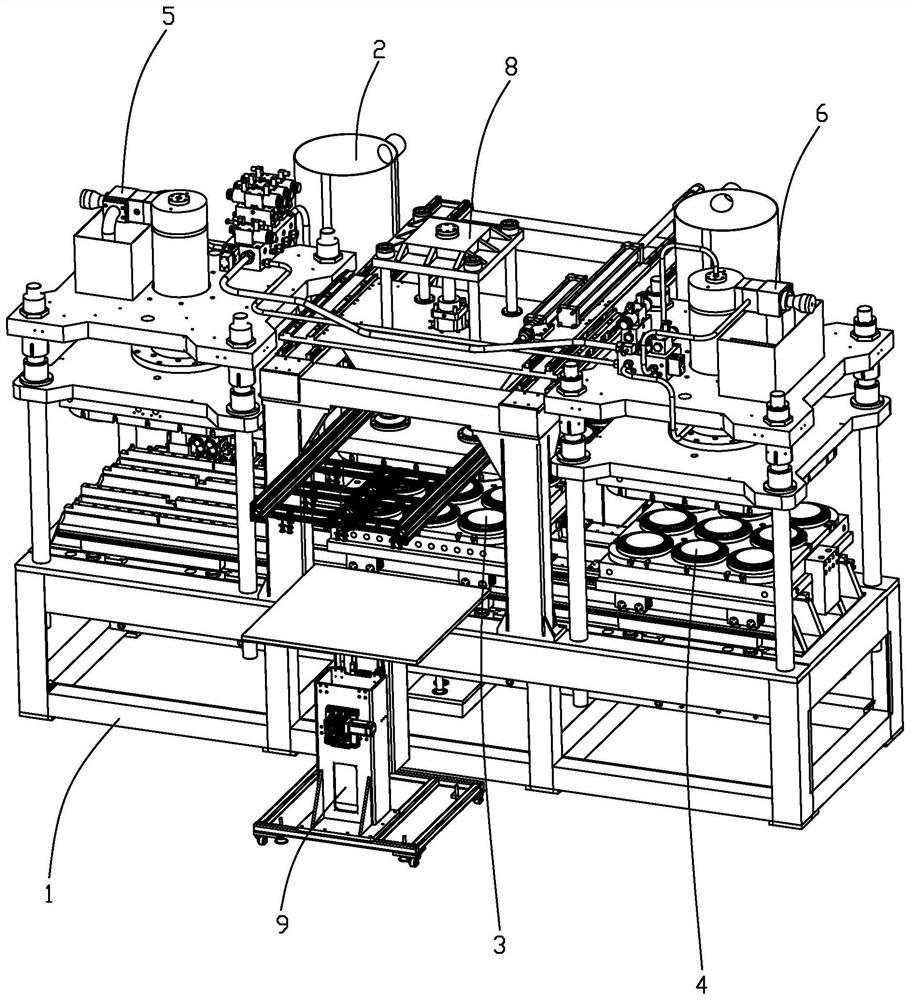

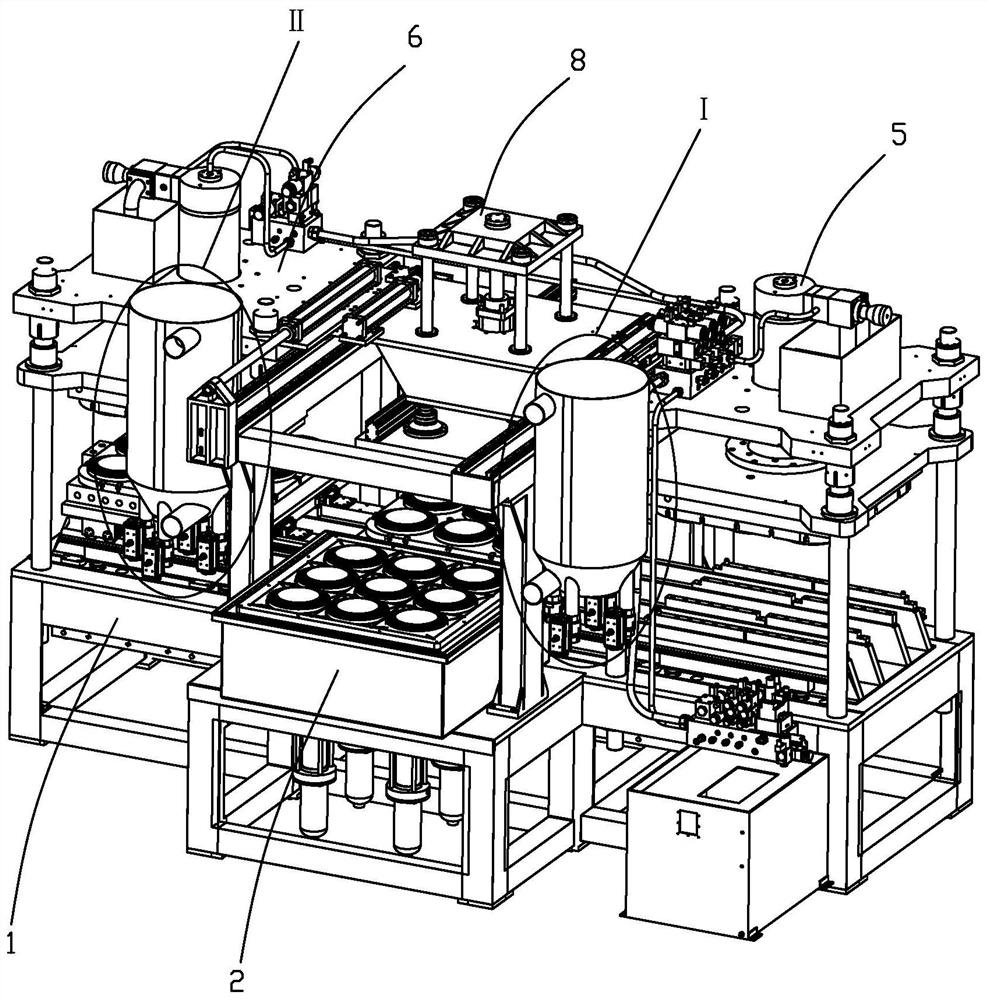

[0085] The present application will be described in further detail below through specific embodiments in conjunction with the accompanying drawings.

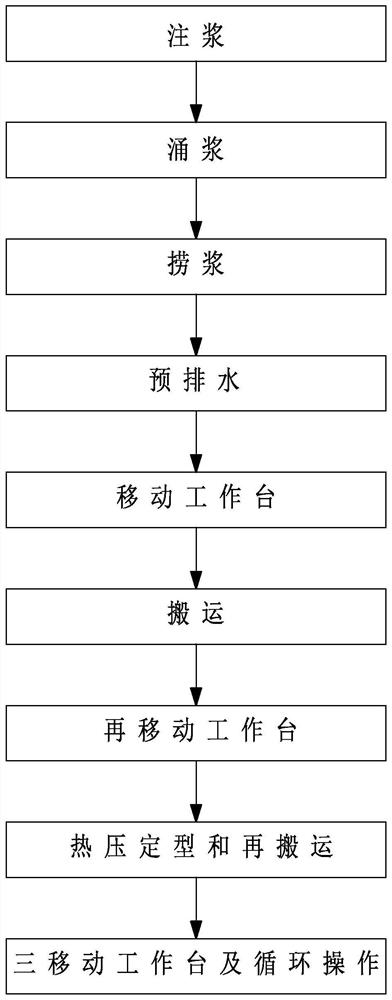

[0086] Such as Figure 1-15 As shown, the paper mold intelligent automatic forming process includes the following steps:

[0087] Step 1, grouting: open the left grouting bucket 24 and the right grouting bucket 25 respectively arranged on the left and right sides of the pulp tank 21, so that the left grouting bucket 24 and the right grouting bucket 25 inject into the pulp tank 21 at the same time pulp;

[0088] Step 2. Flushing pulp: the pulp gushes out from the lower side inside the pulp tank 21 to the upper side inside the pulp tank 21;

[0089] Step 3, pulp extraction: when the liquid level sensor detects that the pulp in the pulp tank 21 reaches the limited position, the liquid level sensor sends a start signal to the upper and lower drive group 23, and then the upper and lower drive group 23 receives the start signal and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com