Measuring device for crushing of soil particles around pile and measuring method of measuring device

A technology of measuring device and measuring method, which is applied in the field of foundation soil survey, construction, infrastructure engineering, etc., can solve the problems of small size, unable to explain the broken state of particles around the pile, and difficult to obtain the original sample of broken soil particles around the pile, etc. , to achieve the effect of convenient operation, economical reliability and improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] This embodiment discloses a device for measuring the crushing of soil particles around a pile, including a testing device and an image acquisition device.

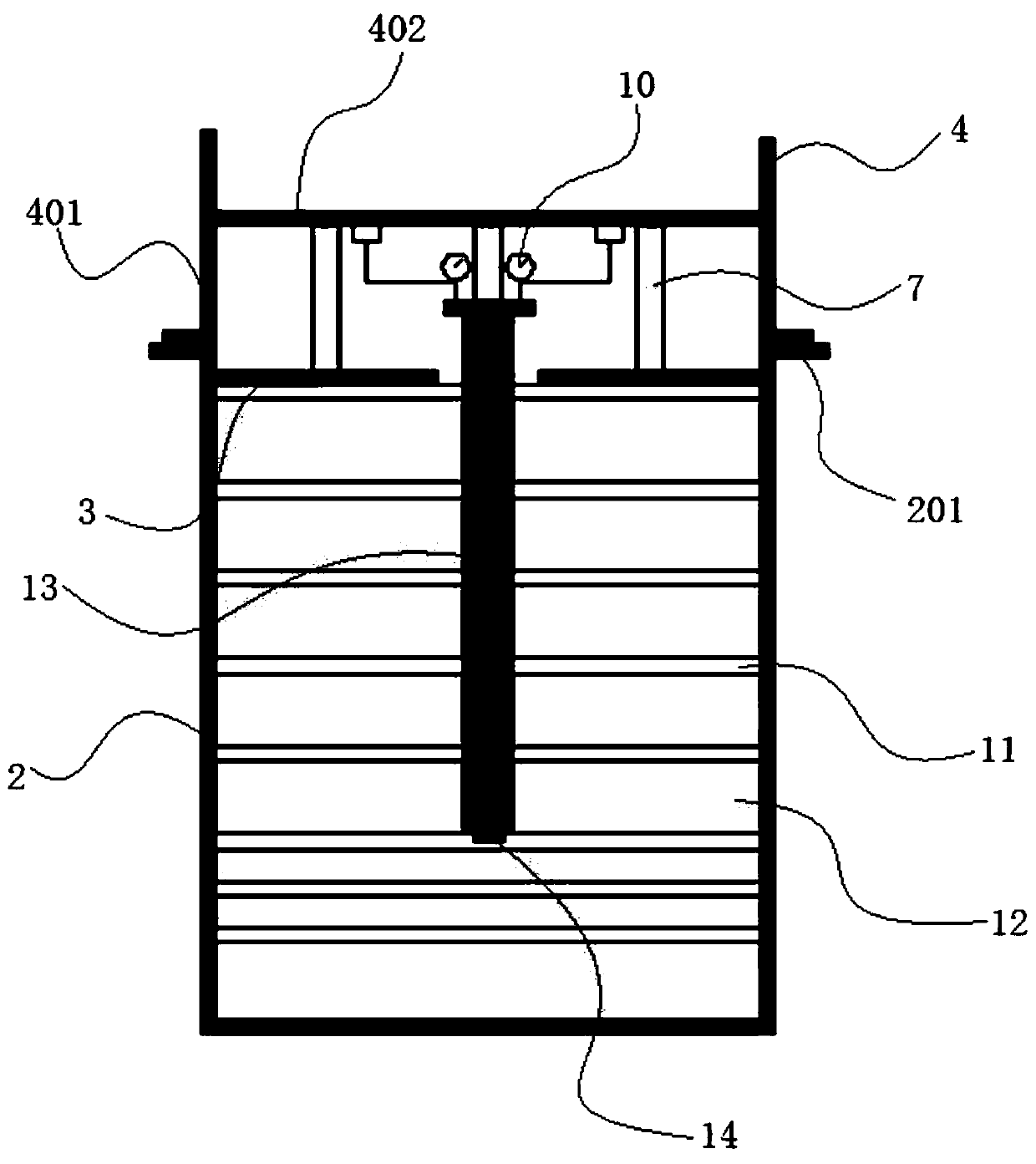

[0057] The test device includes a model test box body 2 , a load plate 3 , a reaction force frame 4 , a model pile 6 and a jack 7 .

[0058] The reaction force frame 4 is a door-shaped reaction force frame, which includes two columns 401 and a beam 402 connected between the two columns 401 . The upper opening of the model test box body 2 has an outer crimp 201 . The two columns 401 are arranged on the outer curl 201 . The model test box 2 is arranged in the test center area of the reaction force frame 4 .

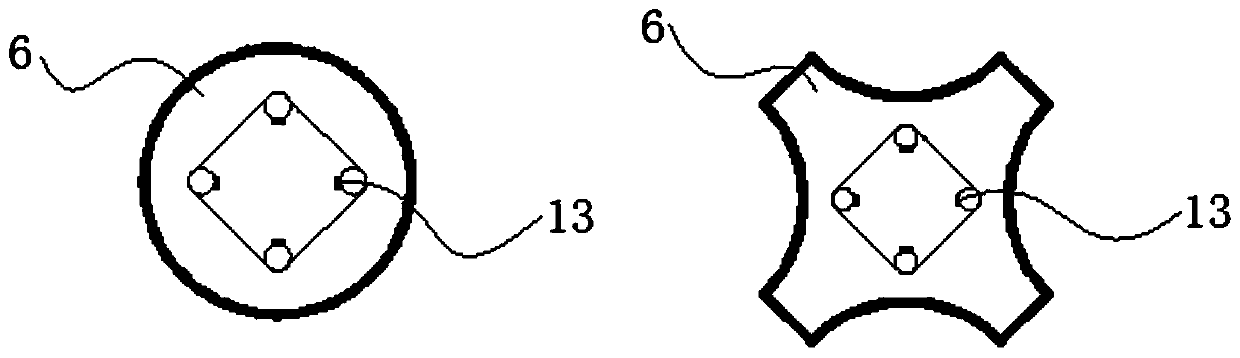

[0059] The model test box 2 is a transparent rectangular box with an open upper end. The inner cavity of the model test box 2 is filled with soil materials in layers and partitions. The soil material includes mixed dyed soil particles 11 and undyed soil particles 12 of the same grade. In actual production,...

Embodiment 2

[0064] This embodiment discloses a measuring method using the measuring device described in Embodiment 1, comprising the following steps:

[0065] 1) According to the simulated working conditions, select the soil particle material and the corresponding industrial dyeing agent. Wherein, the industrial dyeing agent is bright and uniform in color, and has no obvious influence on the crushing properties of soil particles. It is advisable to carry out comparative tests on the compression and crushability of dyed and undyed soil particles.

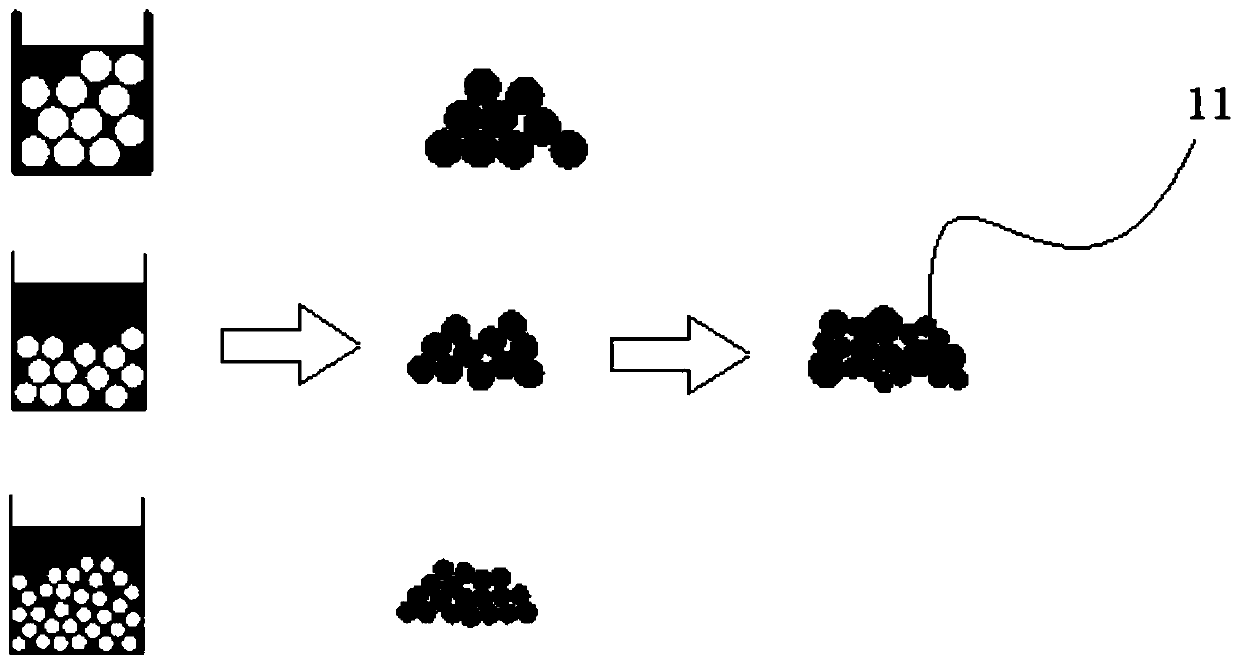

[0066] 2) The soil particle material is sieved into multiple particle size groups, and the soil particle materials of different particle size groups are dyed in different colors for calibration. The maximum particle size of the soil particle is less than one-tenth of the diameter of the model pile 6 to be studied. see figure 2 The soil particle materials of different particle size groups are respectively soaked in dyeing buckets equipped with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com