An Integrated Composite Nozzle Based on Gradient Material

A gradient material and gradient change technology, which is applied in the direction of jet propulsion devices, machines/engines, rocket engine devices, etc., can solve the problems of complex manufacturing process and hidden dangers of nozzle structure reliability, so as to improve reliability, realize lightweight, Enhance the effect of mutual coupling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

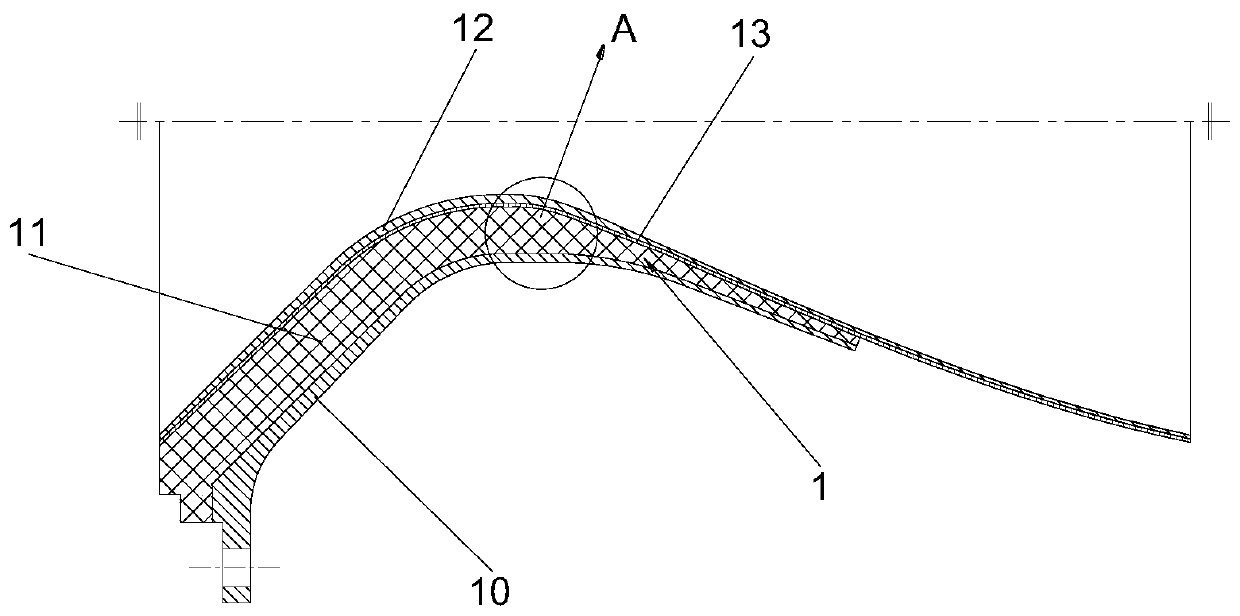

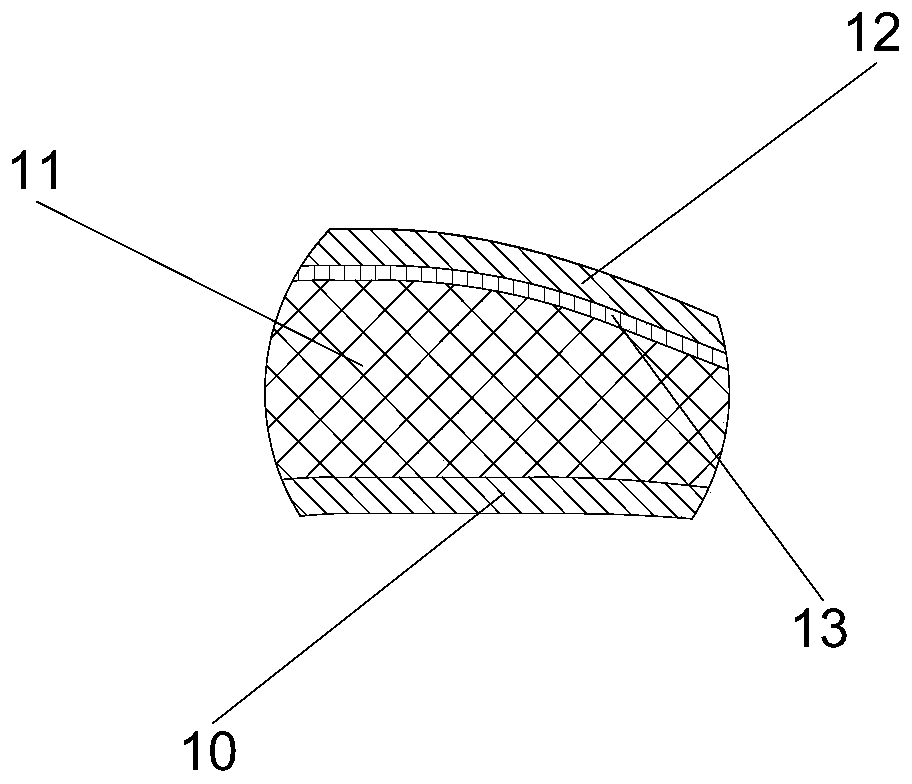

[0022] see figure 1 and figure 2 As shown, Embodiment 1 of the present invention provides an integrated composite nozzle based on gradient materials, the material composition of the nozzle 1 changes in a gradient from the outer wall to the inner wall of the nozzle 1, and the nozzle 1 includes a nozzle 1 along the nozzle 1. The support layer 10 , the heat insulating layer 11 and the ablation resistant layer 12 are distributed and connected in sequence from the outer wall to the inner wall. In Embodiment 1 of the present invention, the support layer 10 is a bearing layer, and the support layer 10 is the main force-bearing component of the nozzle 1, and is connected to the combustion chamber of the engine through the support layer 10. Therefore, the support layer 10 adopts a metal matrix composite material to realize the bearing. The thermal insulation layer 11 adopts a low thermal conductivity thermal insulation material to play the role of thermal protection; the ablation-res...

Embodiment 2

[0034] see figure 1 and figure 2As shown, Embodiment 2 of the present invention provides an integrated composite nozzle based on gradient materials, the material composition of the nozzle 1 changes in a gradient from the outer wall to the inner wall of the nozzle 1, and the nozzle 1 includes a nozzle 1 along the nozzle 1. The support layer 10 , the heat insulation layer 11 , the transition layer 13 and the ablation-resistant layer 12 are sequentially distributed and connected from the outer wall to the inner wall. The support layer 10 in the second embodiment of the present invention is a bearing layer, the support layer 10 is the main force-bearing component of the nozzle 1, and is connected to the combustion chamber of the engine through the support layer 10, so the support layer 10 adopts a metal matrix composite material to realize the bearing The thermal insulation layer 11 adopts a low thermal conductivity thermal insulation material to play the role of thermal protect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com