Limited space long distance drum-shaped gear transmission dial gauge alignment device

A technology with limited space and drum-shaped teeth, which is applied to measuring devices, mechanical devices, mechanical measuring devices, etc., can solve the problems of difficult alignment, many intermediate links, and narrow space, and achieves good alignment and alignment. Highlight the substantive features and the effect of smooth and smooth production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

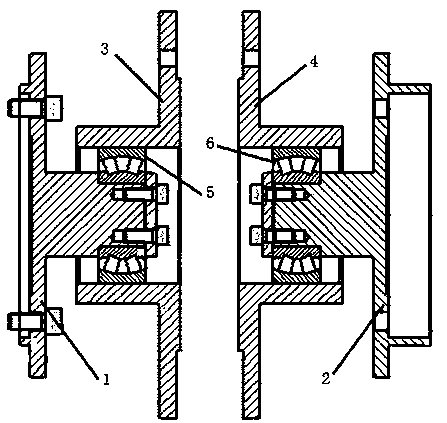

[0012] Example 1, see figure 1 According to the design requirements, the first mandrel 1, the second mandrel 2, the first flange 3 and the second flange 4 are processed, and the first mandrel 1 and the second mandrel 2 are all in one structure. One side is a flange with a branch and bolt holes, one side is an optical axis with threaded holes, the first flange 3 and the second flange 4 are both integral structures, and the outer circle is a flange with bolt holes , the inner circle is a hollow shaft with holes; one side of the first mandrel 1 is connected with the drum-shaped tooth half coupling at the motor end, the other side is connected with one side of the first flange 3, and the drum-shaped half coupling at the motor end is connected with the other side. The part connected to the tooth half coupling is connected by bolts, and the part connected to the first flange 3 is realized by the first bearing 5; then the side of the mandrel 2 is connected to the drum-shaped tooth ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com