Adjustable fixture for torsion shaft of wind turbine above 3 megawatt

A torsion shaft and fixture technology, applied in clamping, manufacturing tools, metal processing machinery parts, etc., can solve the problems of inability to complete one-time processing, reduce production and manufacturing efficiency, troublesome loading and unloading workpieces, etc., to ensure dimensional accuracy and position tolerance. requirements, improve production efficiency, and facilitate disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with embodiments.

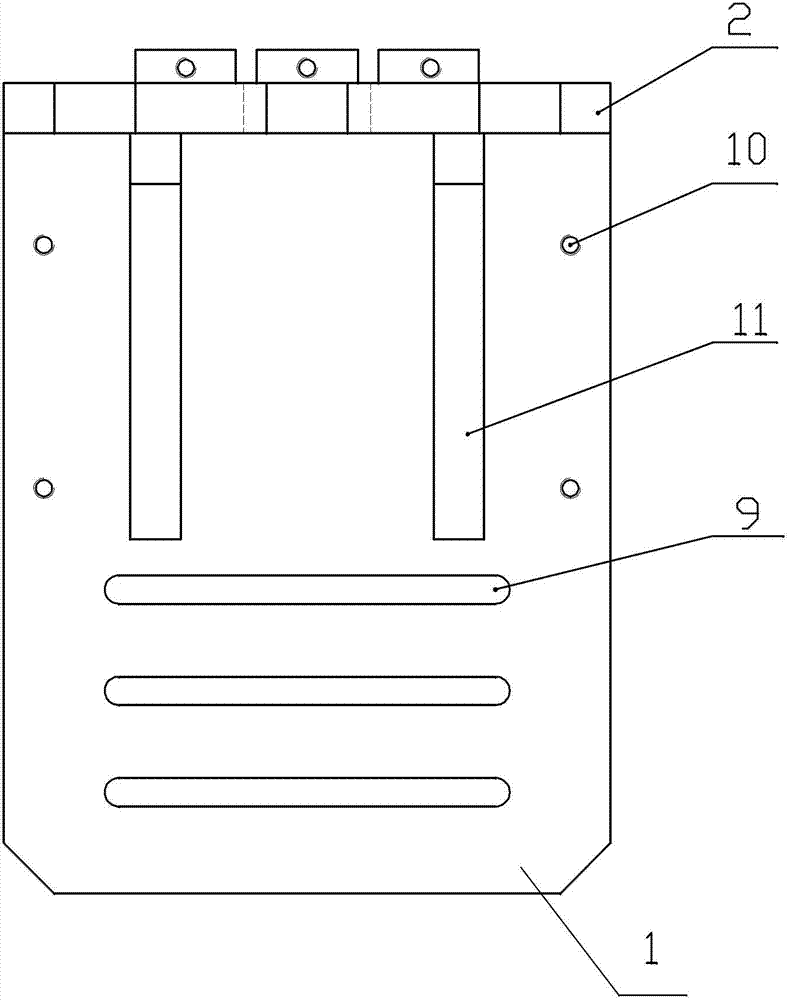

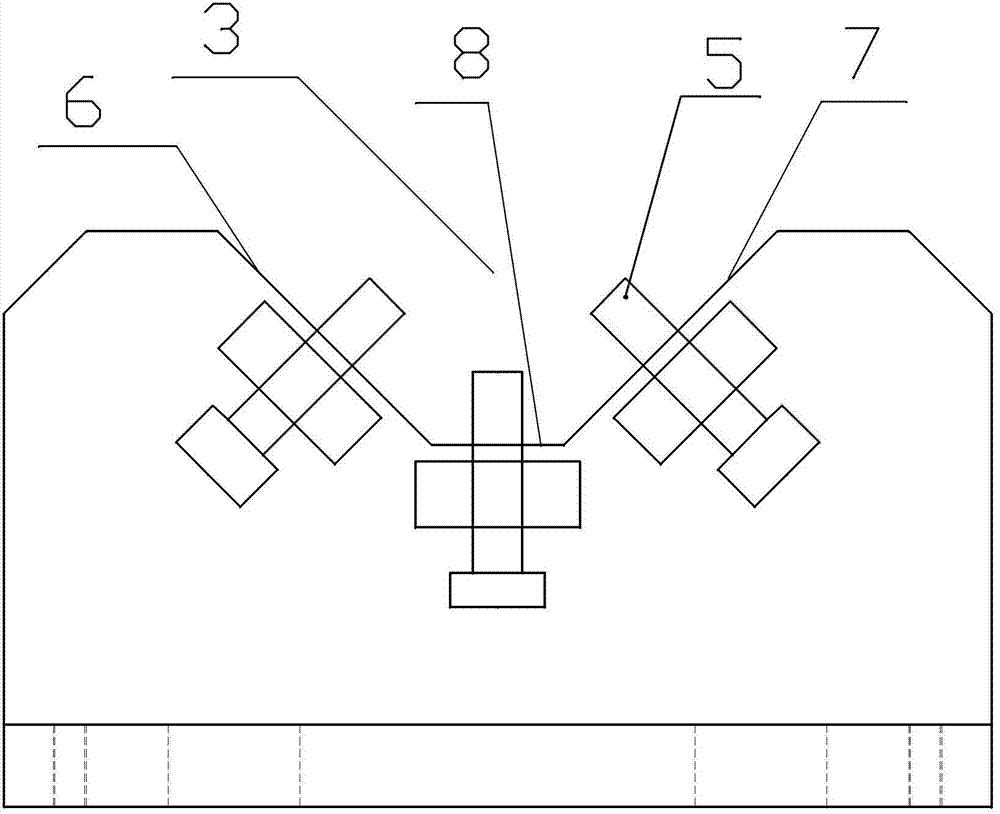

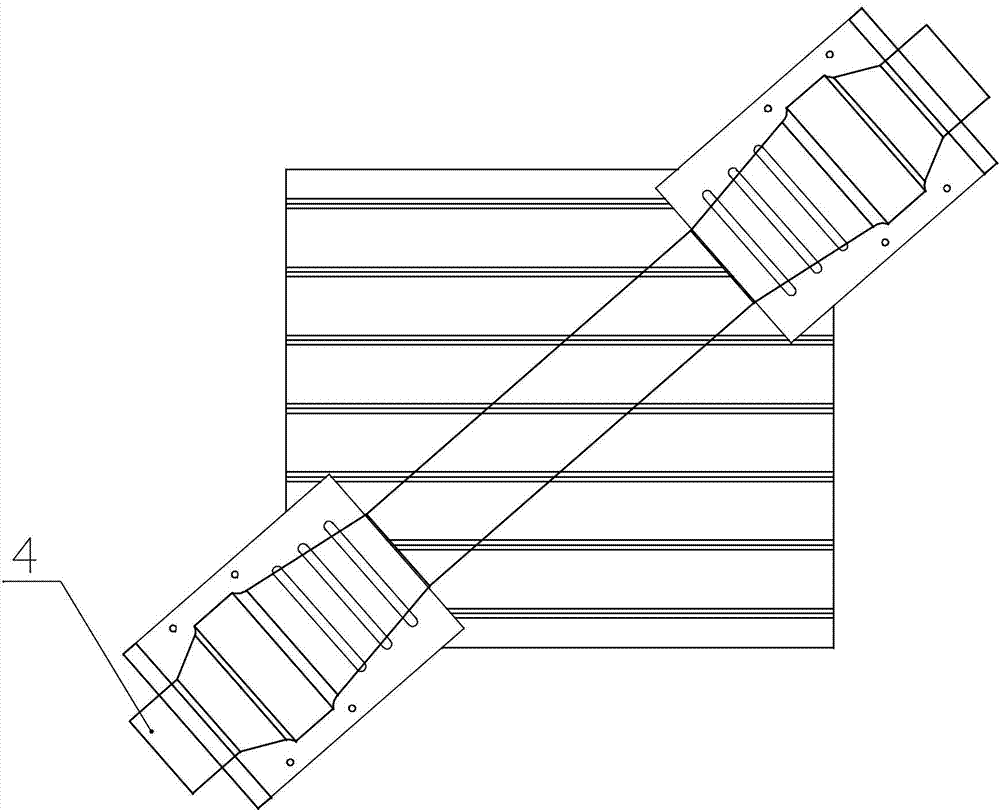

[0016] Such as Figure 1~3 An adjustable clamp for the torsion axis of a fan of more than 3 MW is shown, including a clamp body 1 and a support plate 2 perpendicular to the clamp body. The top of the support plate 2 is provided with a clamp 3 for placing a workpiece, and the clamp 3 is provided with a pair of Hexagon socket bolt 5 for aligning the workpiece 4; a long hole 9 is opened on the main body 1 of the fixture, and the bolt passes through the long hole 9 to tighten the fixture to the worktable. The main body 1 is also provided with a bolt hole 10, and the pressure plate passes through the bolt hole 10 The work piece 4 is pressed tightly; the clamp is also provided with a rib 11 that strengthens and supports the support plate 2.

[0017] As a preferred embodiment of the present invention, the hexagon socket bolt 5 extends from the clamping opening 3 of the supporting plate 2 int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com