Mechanical failure analysis method based on wavelet fuzzy recognition and image analysis theory

A technology of mechanical faults and analysis methods, applied in the field of signal processing, can solve problems such as difficult to deal with non-stationary signals, and diagnostic techniques that cannot meet diagnostic requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

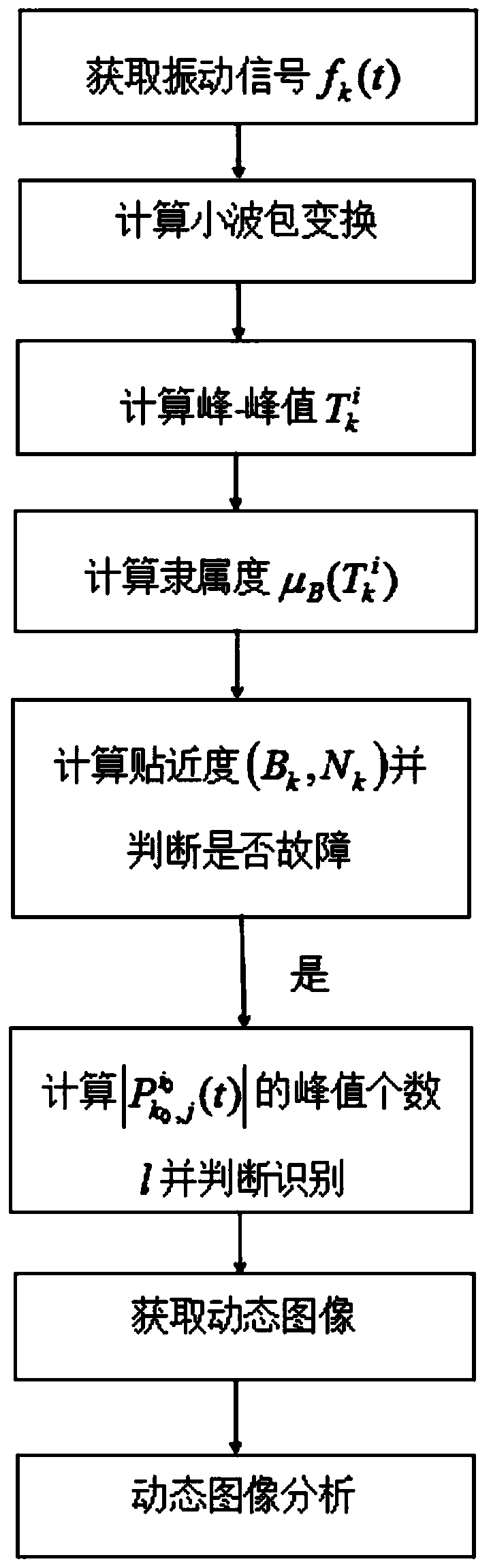

[0042] Such as figure 1 , using the mechanical failure analysis method based on wavelet fuzzy recognition and image analysis theory of the present invention to analyze the failure of rotating gears.

[0043] First, the vibration sensor is used to obtain the vibration signal f k (t) As the signal to be analyzed, the vibration signal f k (t) is determined by K vibration measuring sensors placed at different positions of the rotating machine. Assume that the vibration signal of the rotating gear is measured by K vibration sensors placed in different positions, so as to obtain K groups of vibration signals reflecting the operating state of the rotating gear {f k (t), t=1,2...N, k=1,2...K}.

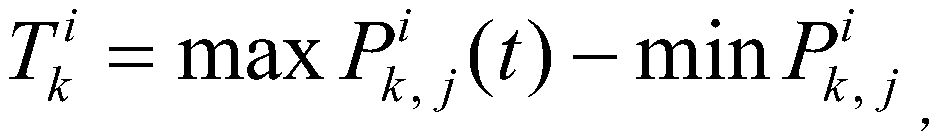

[0044] Then, for the pair of vibration signals f k (t) Decompose 4 layers of wavelet packets to get 2 4 K group weight

[0045] Then, determine whether there i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com