A method and apparatus for analyzing a semiconductor wafer

A semiconductor and wafer technology, applied in the field of defect analysis, can solve problems such as inability to monitor and analyze high defects, and achieve the effect of long-term effective monitoring and analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

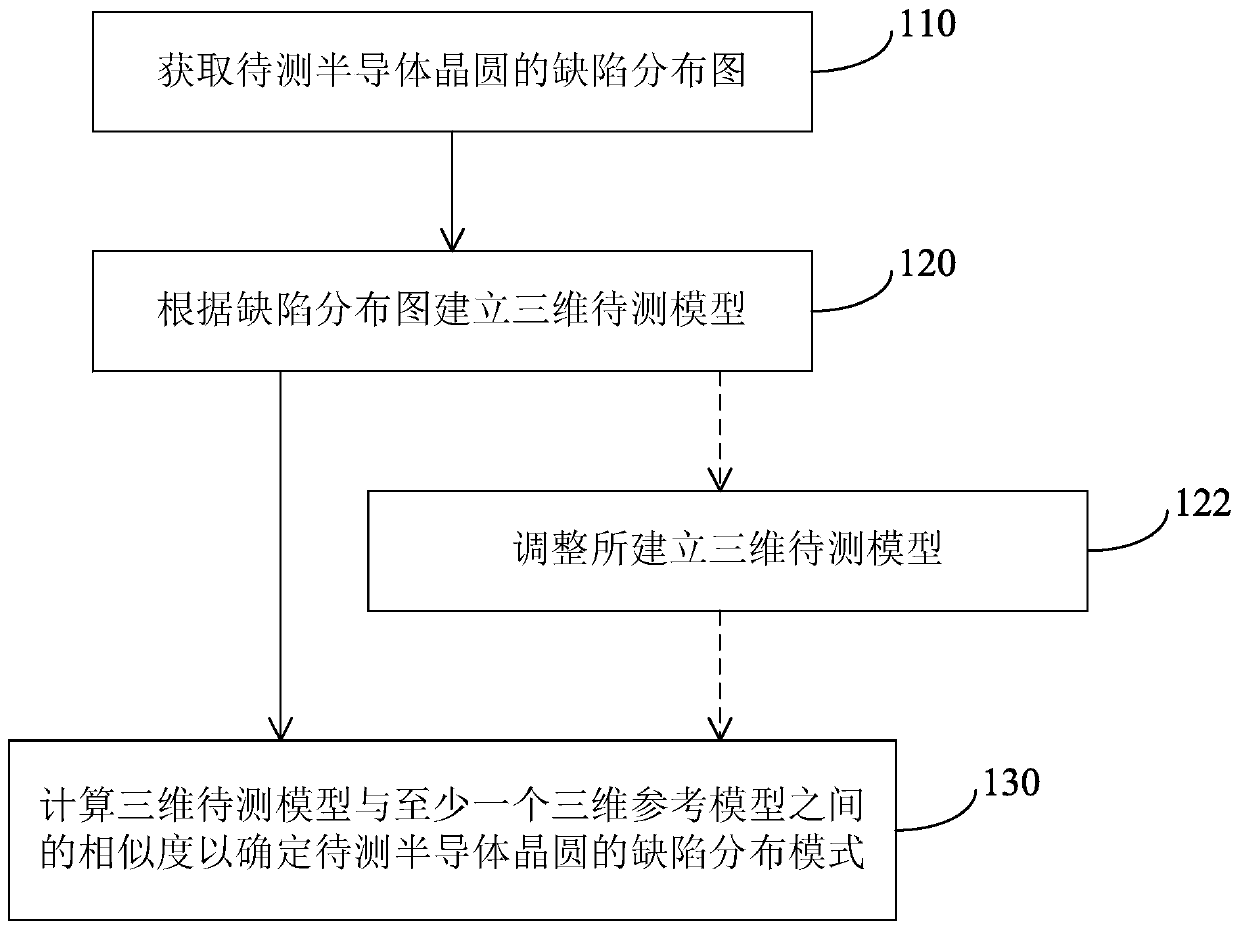

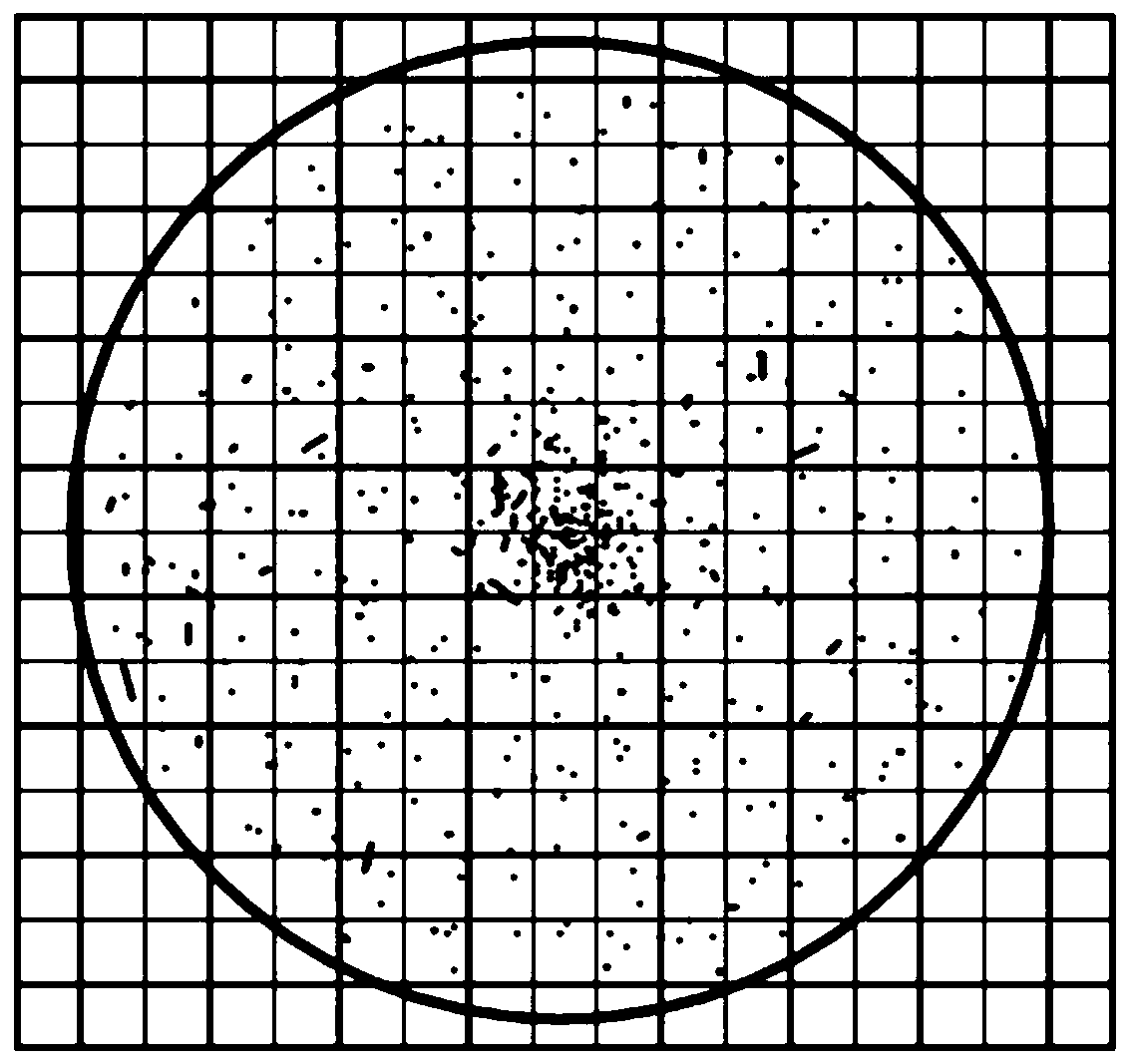

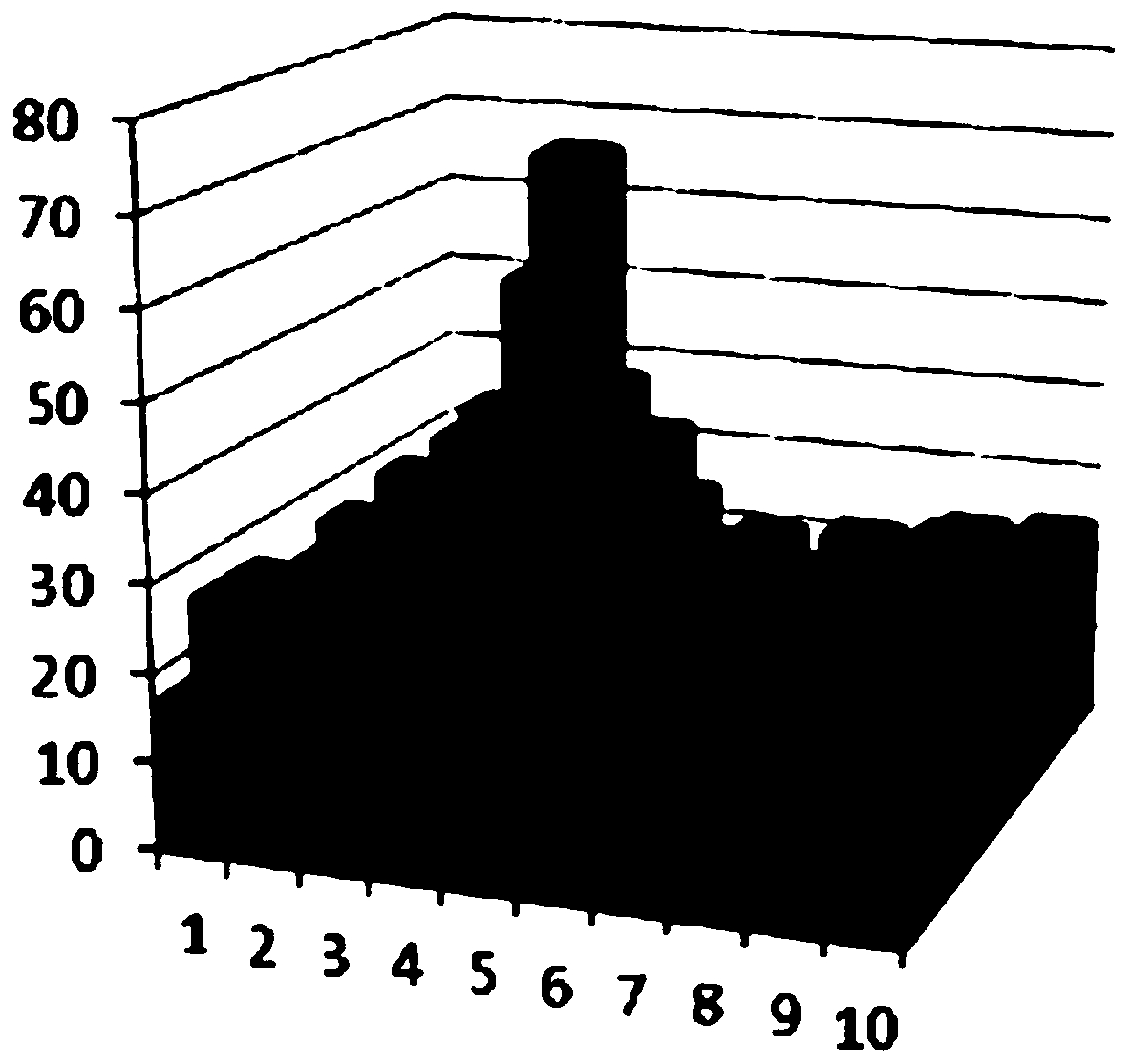

Method used

Image

Examples

Embodiment Construction

[0069] In the following detailed description, numerous specific details are set forth in order to provide a better understanding of the present invention. It will be apparent, however, to one skilled in the art that the practice of the present invention need not be limited to these specific details. In other words, well-known structures and devices are shown in block diagram form and not in detail in order to avoid obscuring the invention.

[0070] Readers are invited to pay attention to all documents and documents submitted simultaneously with this specification and open to public inspection of this specification, and the contents of all such documents and documents are incorporated herein by reference. All the features disclosed in this specification (including any accompanying claims, abstract and drawings), may be replaced by alternative features serving the same, equivalent or similar purpose, unless expressly stated otherwise. Thus, unless expressly stated otherwise, ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com