A method for detecting the falling of vending machine goods based on dual cameras

A vending machine and dual-camera technology, applied to coin-operated equipment for distributing discrete items, coin-operated equipment for distributing discrete items, image analysis, etc., can solve the difficult to determine delivery time and cannot be detected Problems such as light-weight goods and shipment failures, to achieve the effect of avoiding image mutation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030]The invention will be described below with reference to the drawings.

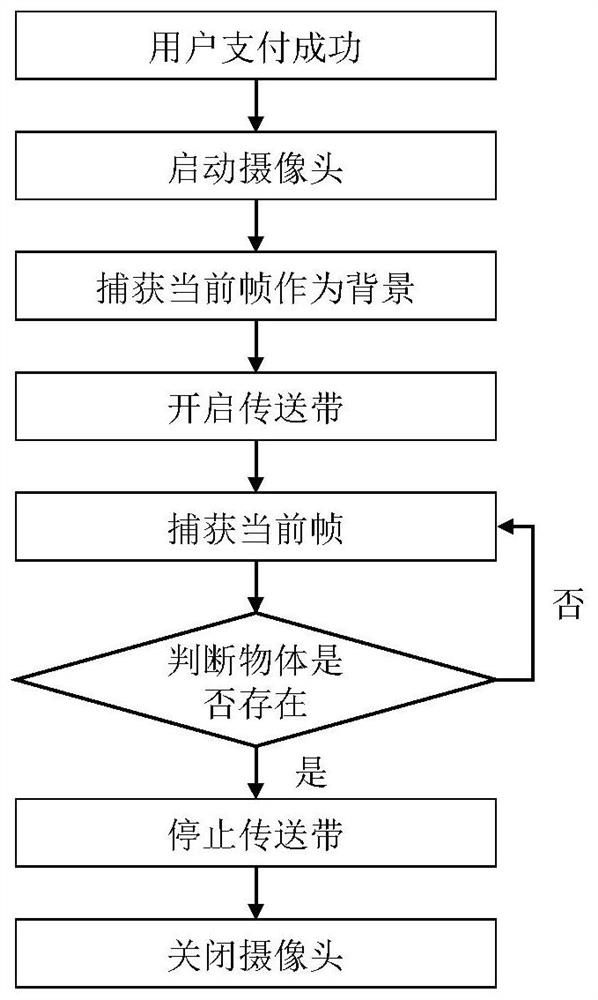

[0031]Appendfigure 1The present invention is shown in the dual-camera-based automatic vending machine cargo drop detection method, including an automatic vending machine with a cloud station; the two side baffles of the vending machine is separately installed; The diagonal placement of the camera; the two side baffles of the cloud is pasted to draw stickers with black and white chess slats; the test step is:

[0032](1) When the user's payment is completed, the PTZ rises to the layer where the cargo is located. At this time, the camera is started to capture the camera on both sides of the cloud.

[0033](2) Start the image processing module of the machine to process the capture image, first cut the image according to the pre-measured cloud side panel, cut the captured image, remove the unrelated area, then make grayscale processing of cropping images, finally, use The Sobel edge detection operator performs edge det...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com