Electric vehicle power battery lower case

A technology for power batteries and electric vehicles, applied in the direction of secondary batteries, battery pack components, circuits, etc., can solve the problems of unfavorable battery system lightweight and system energy density, impact on ride comfort, cumbersome assembly process, etc., to achieve The effect of speeding up the production cycle, improving ride comfort, and reducing the number of assembly parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

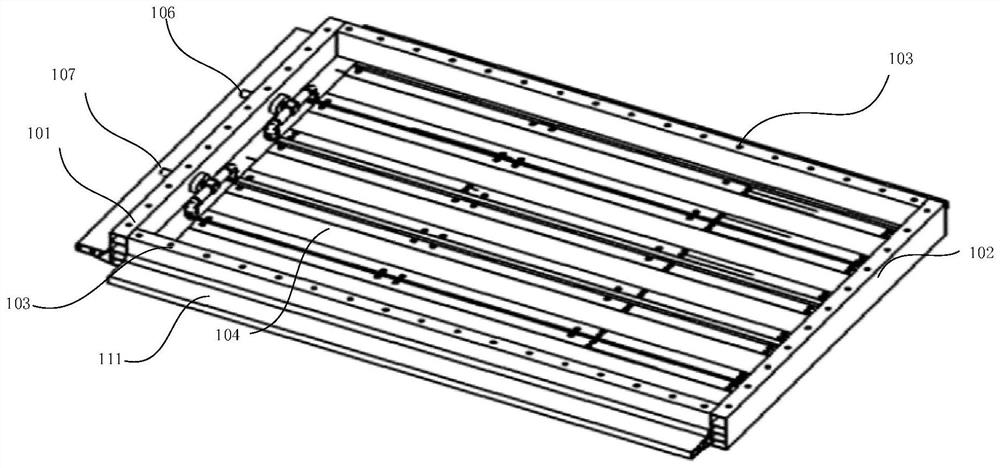

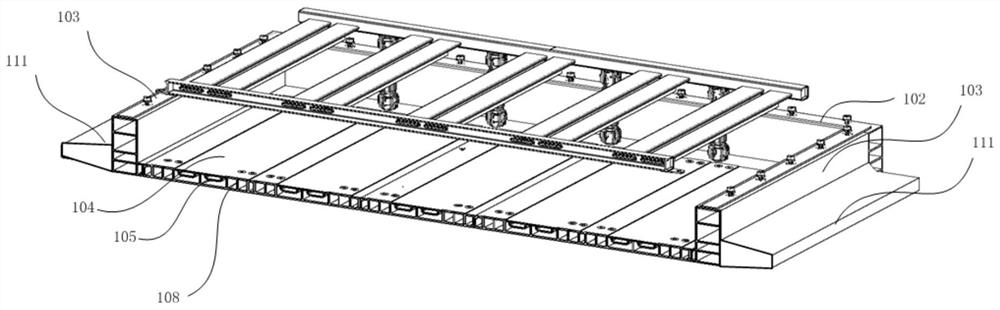

[0027] Such as figure 2 Shown is a schematic structural view of the lower casing 100 of the power battery of an electric vehicle according to the present invention, including: a front bracket 101 of the lower casing, a rear bracket 102 of the lower casing, and a front bracket 101 of the lower casing and a rear bracket 102 of the lower casing. The two lower shell side brackets 103, the water inlet 106, and the water outlet 107 on the side are in the space surrounded by the lower shell front bracket 101, the lower shell rear bracket 102, and the two lower shell side brackets 103. At least one lower shell inner bracket 104 extending from the lower housing front bracket 101 to the lower housing rear bracket 102 and hollow is provided, at least one lower housing inner bracket 104 is provided with the lower housing inner bracket The lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com