On-line remanufactured production method based on automatic identification of multiple models in main line buffer area

A technology of automatic identification and production methods, applied in the fields of motor vehicles, transportation and packaging, etc., which can solve problems such as energy and labor time waste, large impact on the production capacity of basic vehicles, identification omissions or errors, etc., to achieve short restructuring cycles and improve efficiency , to avoid the effect of quality problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] A certain car model launched a fashion version after the SOP (Standard Operating Procedure, meaning: standard operating procedure). Since there was no fashion version model in the early product planning, the mold could not increase the step installation holes, and the cost of new molds was too high. Therefore, the fashion version The vehicle model process strategy is off-line restructuring.

[0057] The original process path for the production of fashion models is: manual opening of 21 nut mounting holes for the complete vehicle off the assembly line, and manual welding of 18 nuts. It will also have a major impact on the production capacity of the main line of the base model.

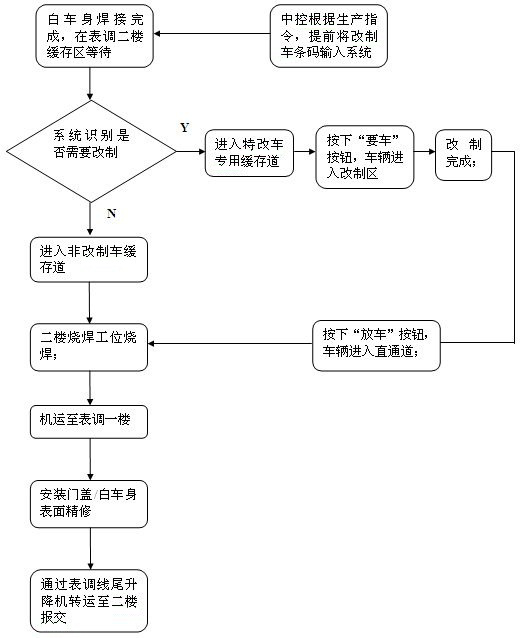

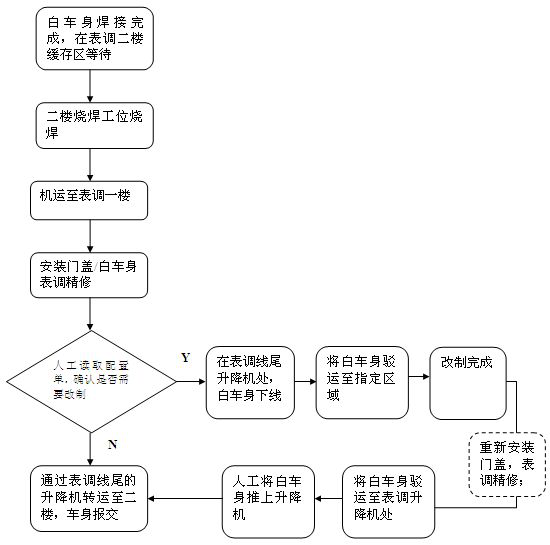

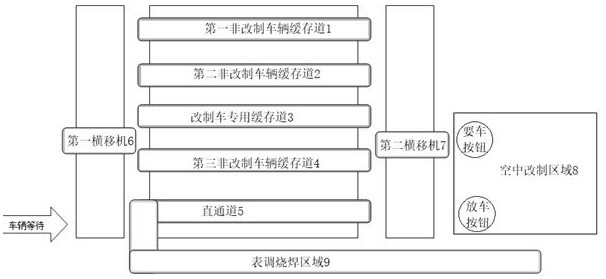

[0058] The process path adopting the present invention is as follows: the central control imports the car number of the day into the RC system of the buffer area, and sets the buffer area 3 as a special buffer lane for remanufactured vehicles; After the RFID head reads the car number, the RC sys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com