Ash removal device before plating for cylinder body electroplating

A pre-plating and cylinder technology, which is applied in the direction of jewelry, etc., can solve the problems of scratching the workpiece, high equipment capacity requirements, non-professionals cannot operate, etc., and achieve the effect of increasing the overall strength, simple and compact structure, and compact structure layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

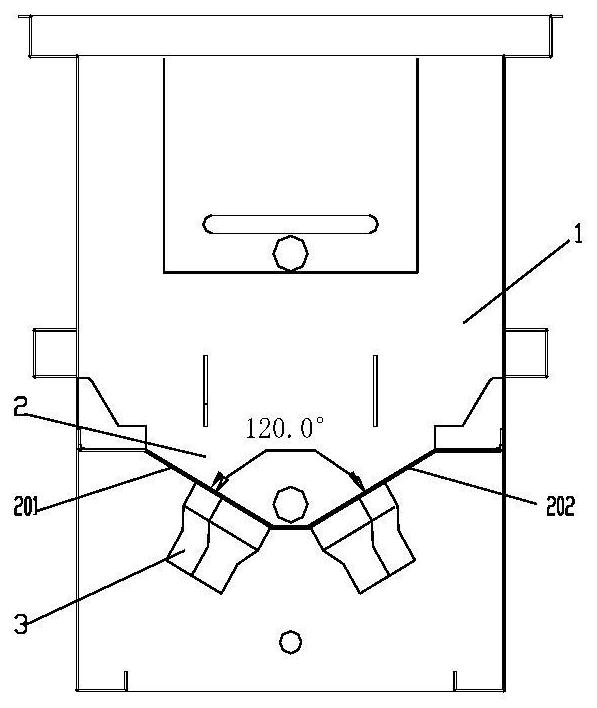

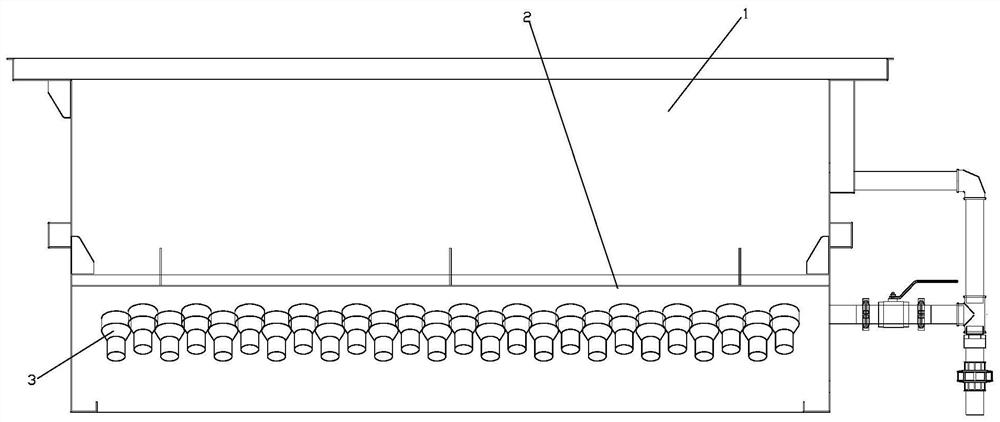

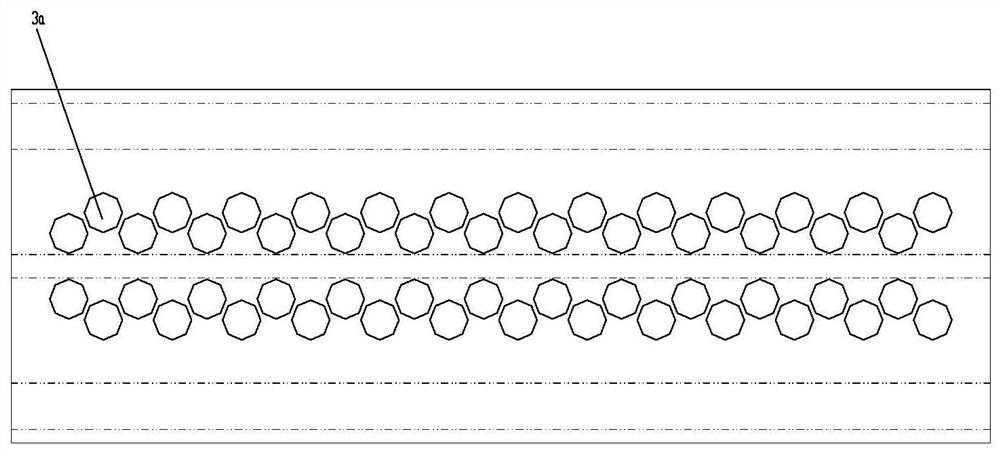

[0022] figure 1 It is a structural sectional view of the present invention, figure 2 for figure 1 Side view (remove one side of the tank wall), image 3 It is the expanded view of the V-shaped groove of the present invention, Figure 4 For the tooling diagram (with workpiece) matched with the present invention, as shown in the figure: the pre-plating ash removal device for cylinder electroplating of the present embodiment includes ash removal tank 1 and an ultrasonic generating assembly, and the ultrasonic generating assembly Including a transducing head 3 (vibrating head) and a driver (for driving the transducing head to generate ultrasonic waves, which belongs to the prior art and will not be described in detail here), the transducing head 3 is located on the lower outer side of the ash removal tank 1 , and the oblique setting makes the ultrasonic generation direction (referring to the main generation direction of the transducing head, which can be understood as the cent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com