Double-hoister scheduling method and system and coke dry quenching equipment

A dispatching method and dispatching system technology, applied in coke ovens, coke cooling, petroleum industry, etc., can solve problems affecting the normal production of the CDQ system, collision accidents of hoist cabs, etc., to improve coke loading efficiency, The effect of avoiding collision accidents and improving operating efficiency and productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

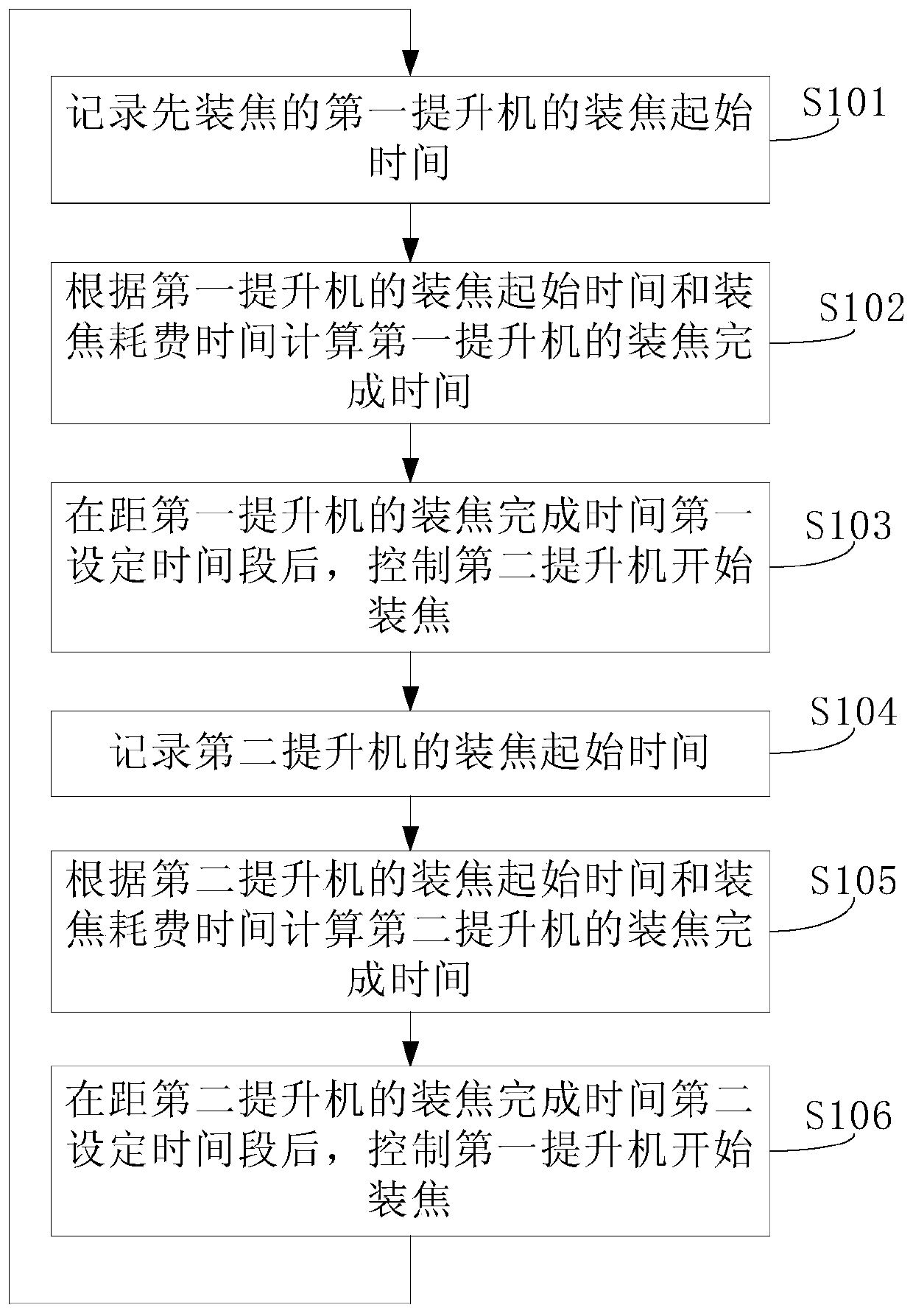

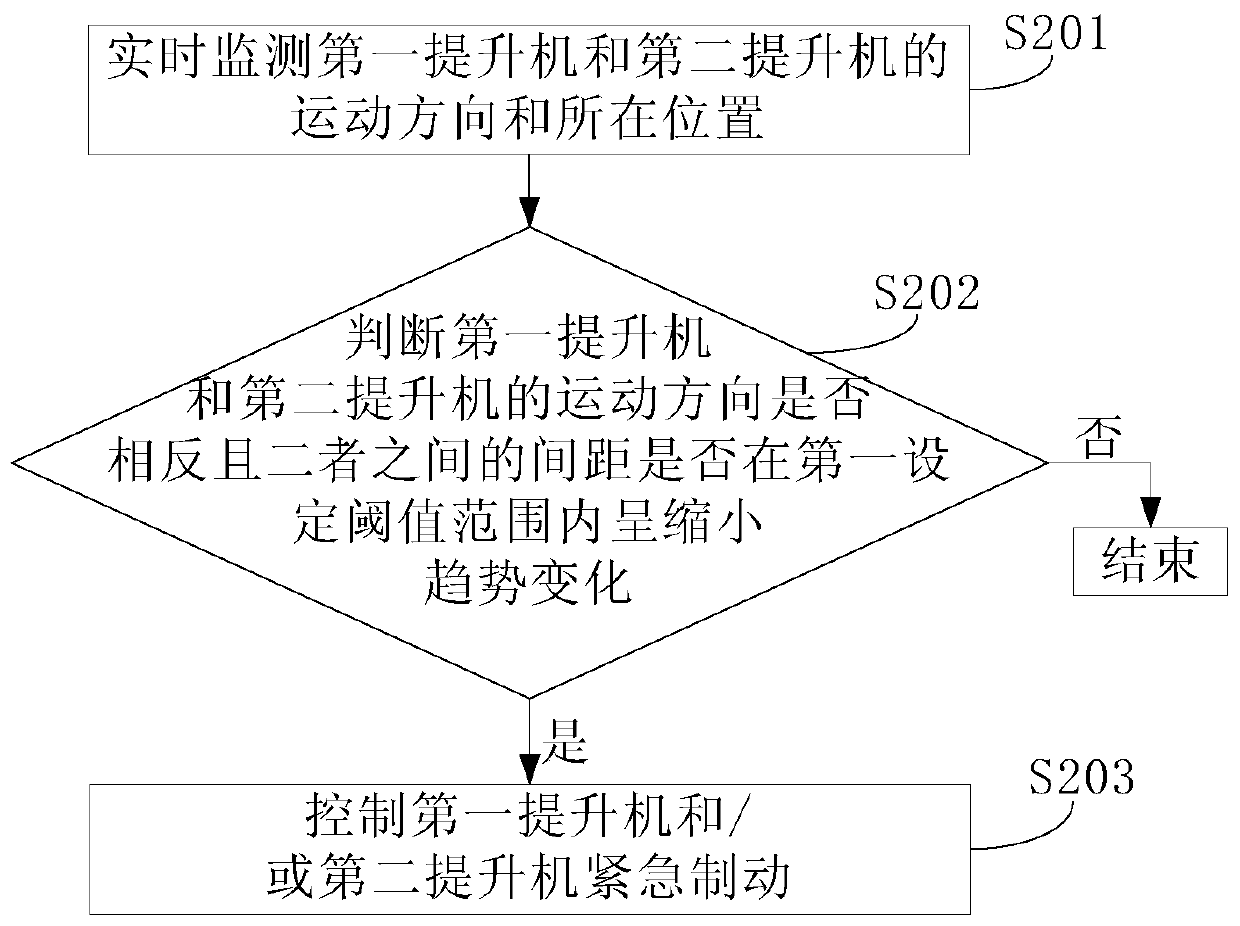

[0080] In order to enable those skilled in the art to better understand the technical solution of the present invention, a double-hoist scheduling method and system and CDQ equipment provided by the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0081] With my country's emphasis on environmental protection in recent years, the environmental protection requirements of the coking industry are also getting higher and higher. As an energy-saving and environment-friendly technology, coke CDQ is widely used in my country. The state also vigorously promotes this technology, and requires coking enterprises to build dry coke quenching within a limited time, so as to reduce the serious pollution caused by the application of conventional wet coke quenching.

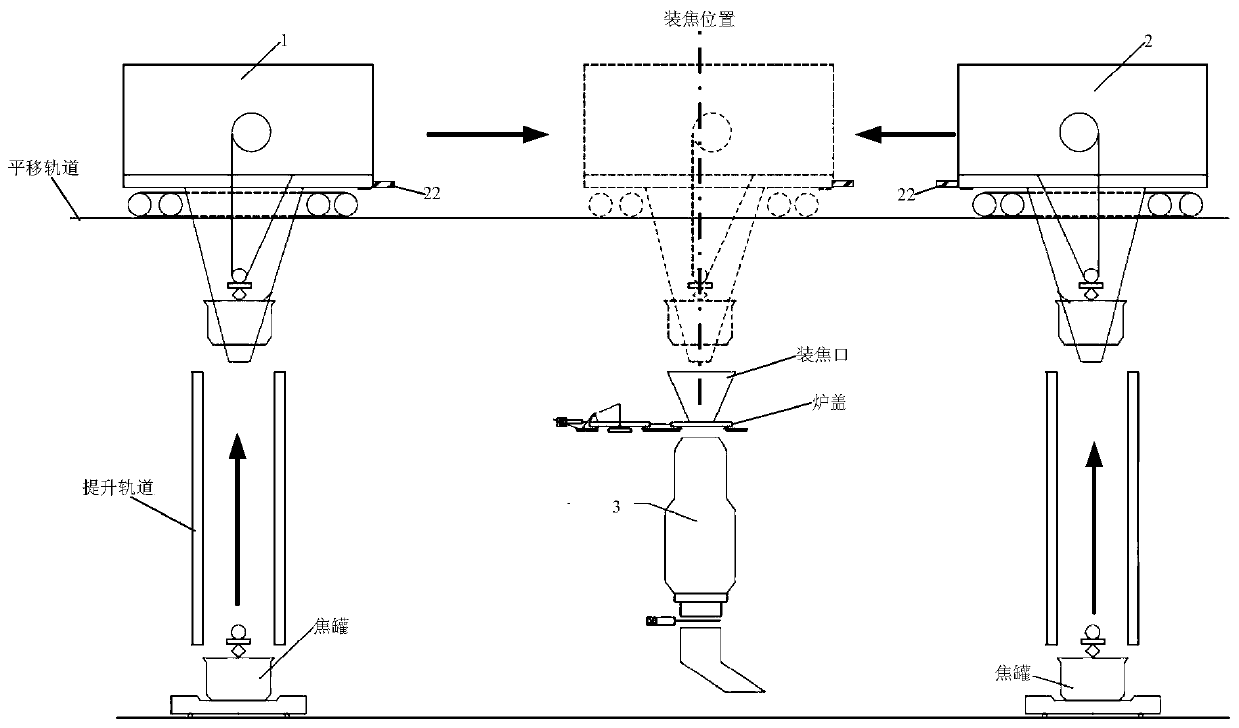

[0082] Therefore, coking enterprises all over the country have launched CDQ construction one after another. Conventional coke CDQ is one hoist c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com