An active prevention and control method for rockburst in gas tunnels under high ground stress

A high ground stress and tunnel technology, which is applied in the direction of gas discharge, earthwork drilling, borehole/well components, etc., can solve the problems of lack of gas tunnel rockburst, rockburst disasters, economic losses, etc., to reduce the amount of fracturing engineering, Reduce the brittleness of rock mass and increase the damage range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

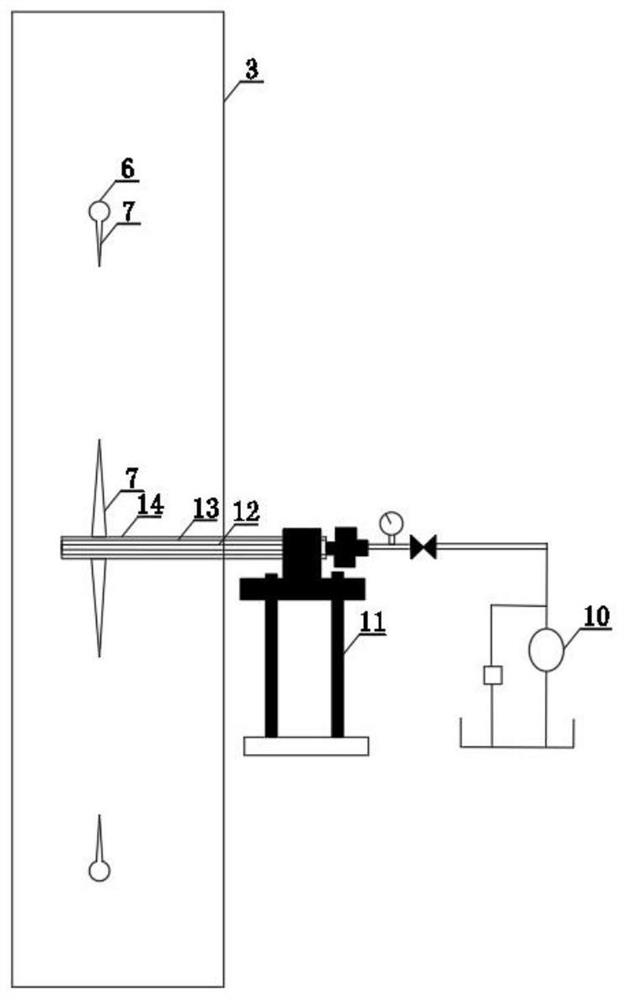

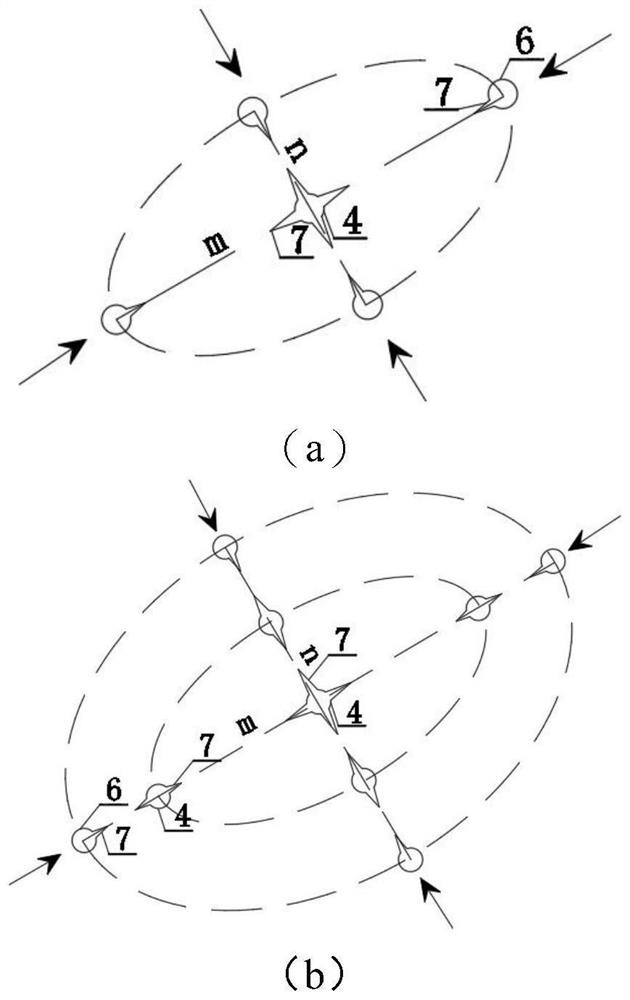

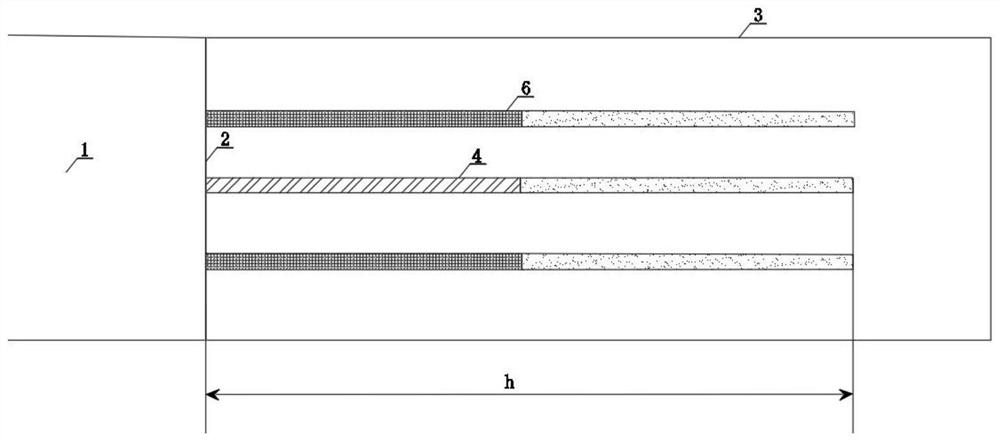

[0058] In this example, if Figure 1 to Figure 6 As shown, the location and range of the rockburst section 3 and the coal-excavation section 9 of the tunnel 1 are determined by using the advanced geological prediction of the tunnel;

[0059] Such as Figure 1 ~ Figure 3 As shown, for rockburst segment 3 has the following steps:

[0060] Step 1: Determine Rockburst Section 3

[0061] Predict the position, intensity and scale of the rockburst section 3 before excavation, and determine the maximum and minimum horizontal stress and direction of the rock mass in the rockburst section 3;

[0062] Step 2: Arranging advanced center hole 4, orientation hole 6 and wedge-shaped groove 7

[0063] If it is the rockburst section 3, when the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com