Firework inner cylinder and firework set-off equipment

An inner tube and fireworks technology, applied in the direction of offensive equipment, pyrotechnics, weapon types, etc., can solve the problems of low production efficiency, explosion tube, safety, reliability and convenience, etc., to reduce transportation and storage costs, sealing Improved air-sealing effect and good air-sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The invention will be further described below in conjunction with the accompanying drawings, but it is not used to limit the scope of the present invention.

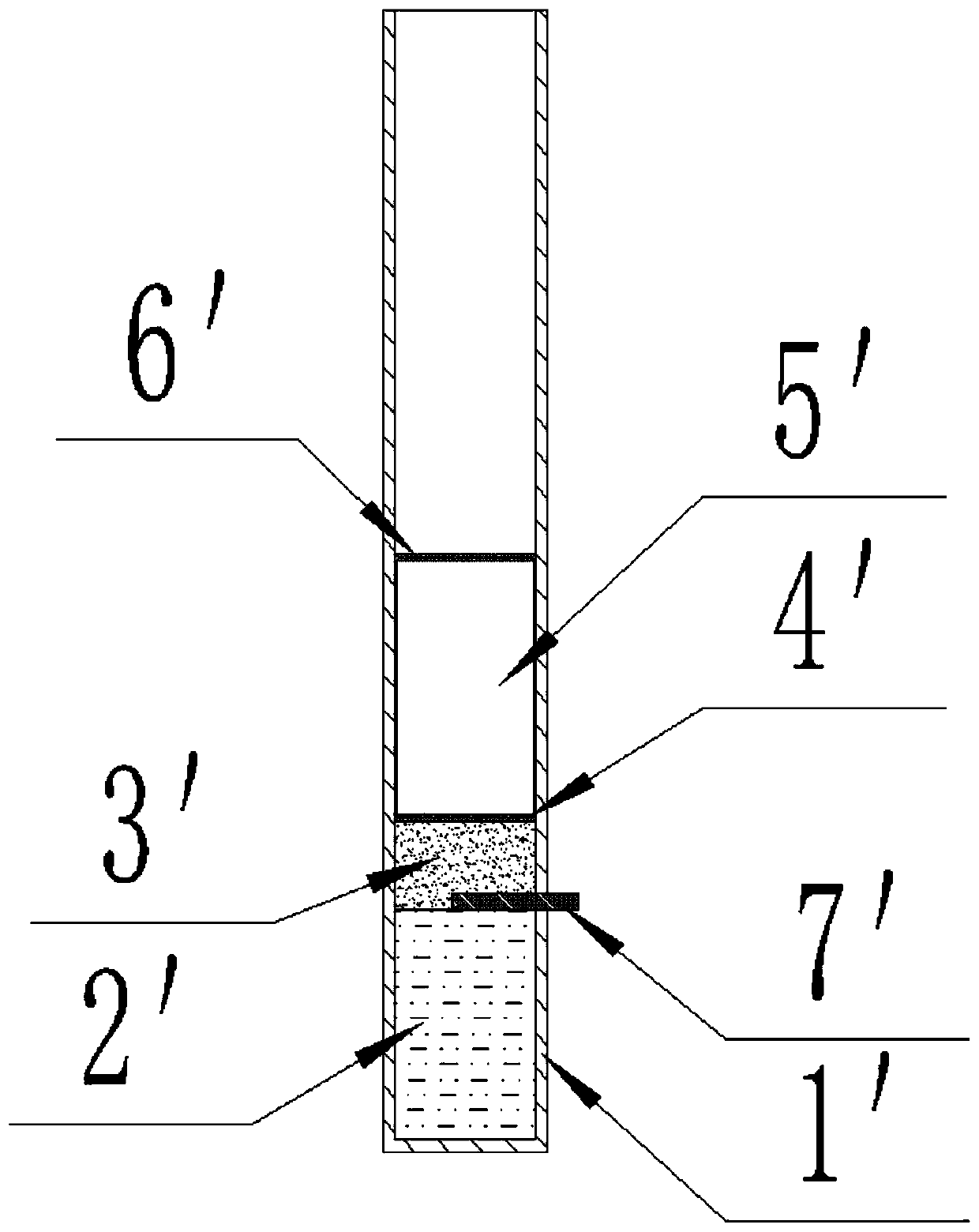

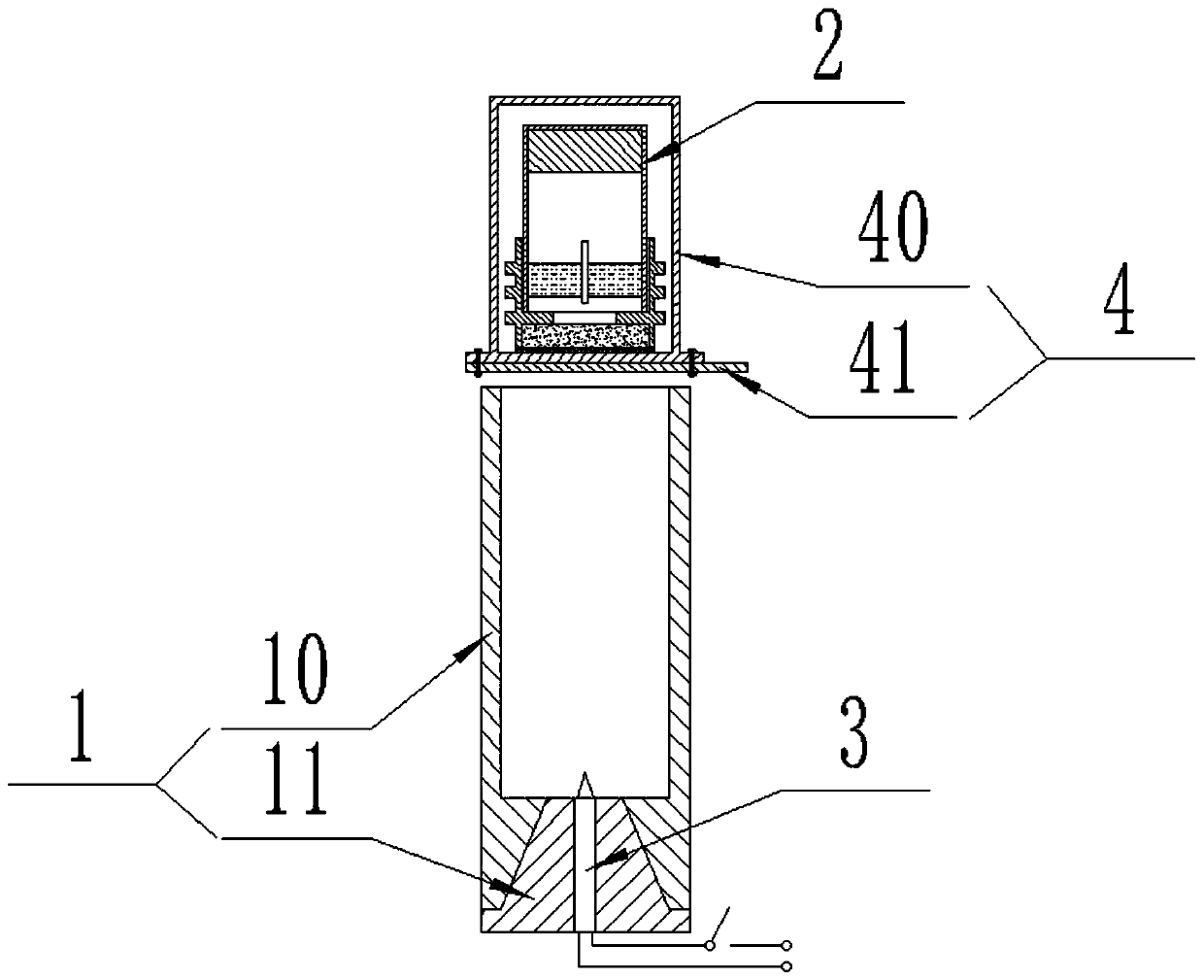

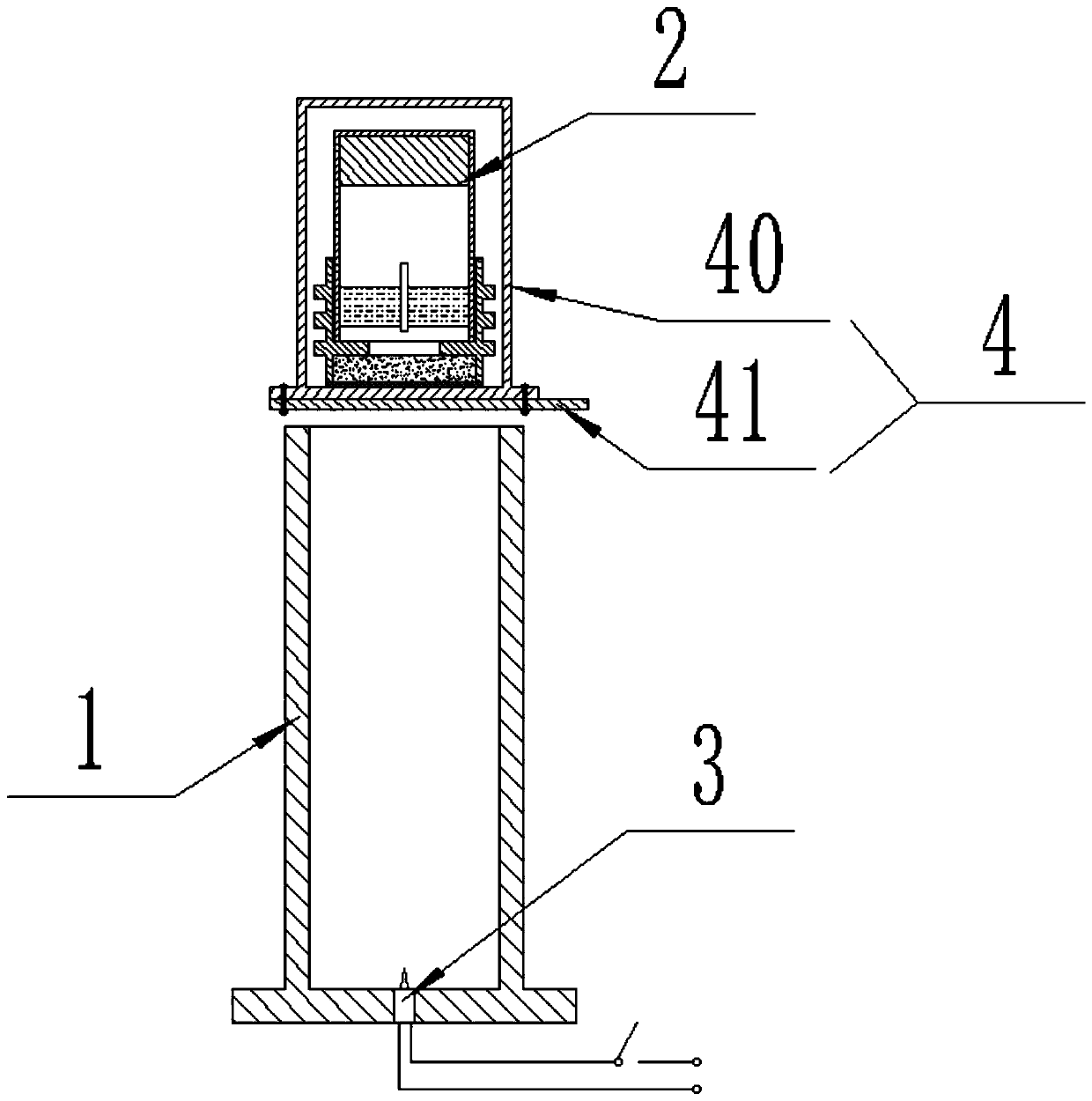

[0051] Such as Figure 2-13 As shown, a firework display device provided in this embodiment includes a launching tube 1 and an inner tube 2. There is a gap between the inner surface of the launching tube 1 and the outer surface of the inner tube 2, and the outer surface of the inner tube 2 is The surface is provided with at least one ring-shaped groove 201 . When the firework display device in this embodiment is a combined firework, it is formed by arranging and combining a plurality of launch tubes 1 .

[0052] In this embodiment, the gap range between the inner surface of the launch tube 1 and the outer surface of the inner tube 2 is generally determined according to the size of the launch tube 1 and the inner tube 2. The larger the size, the larger the gap, and the smaller the size, the smaller the gap. Commo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com