Touch panel and touch panel production method

A touch panel and one-sided technology, which is applied in the printing of special varieties of printed matter, the input/output process of data processing, printing technology, etc., can solve the problems of difficult to obtain electrical connection status, increase of contact resistance, etc., and achieve improved electrical connection Quality, good production results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Hereinafter, examples of this invention will be described.

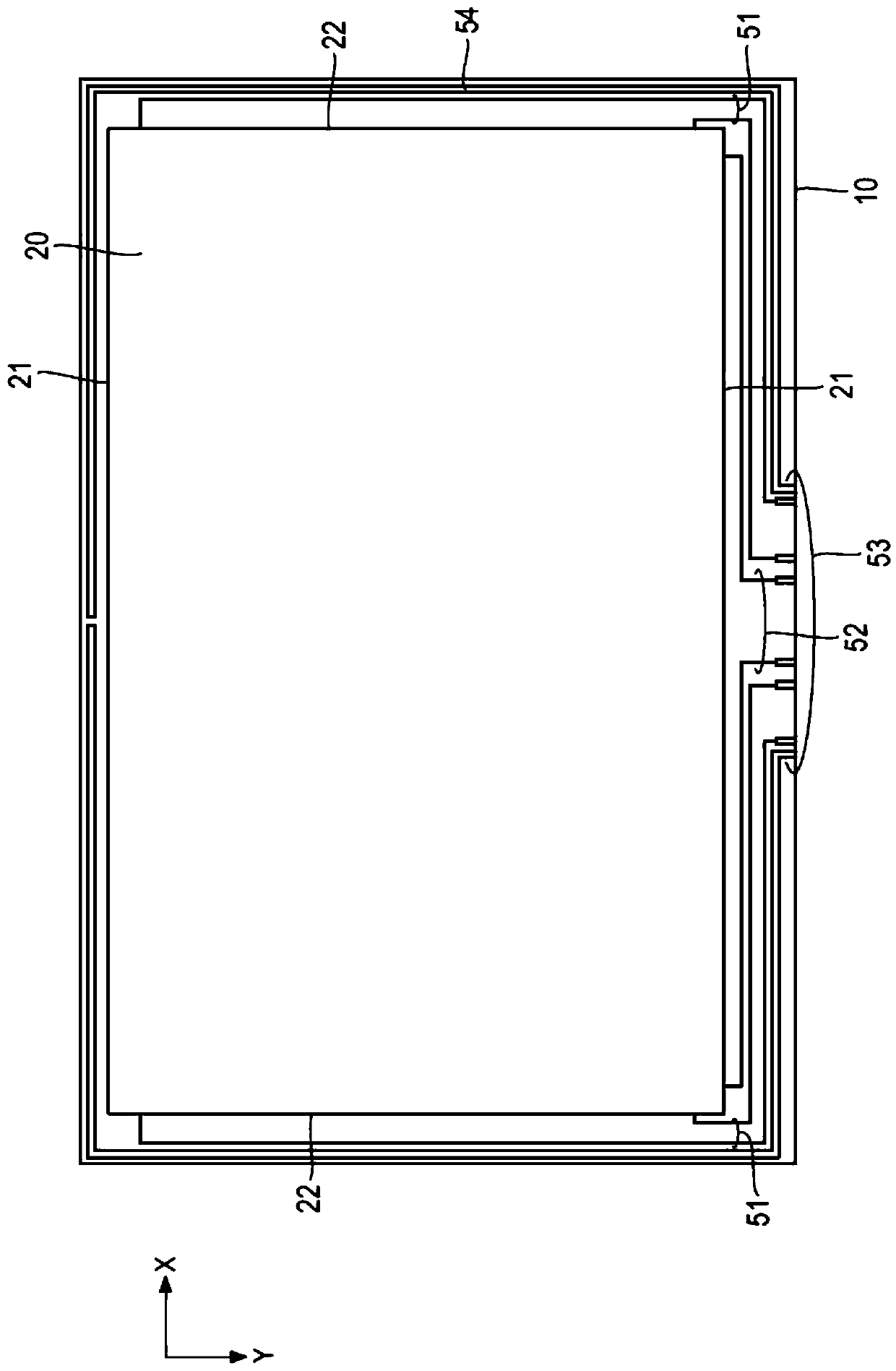

[0033] Figure 4A , Figure 4B and Figure 5 The details of the external connection terminals included in one embodiment of the touch panel of the present invention are shown, Figure 6 It is an example of the touch panel of this invention which shows the FPC which connected the external circuit to the external connection terminal.

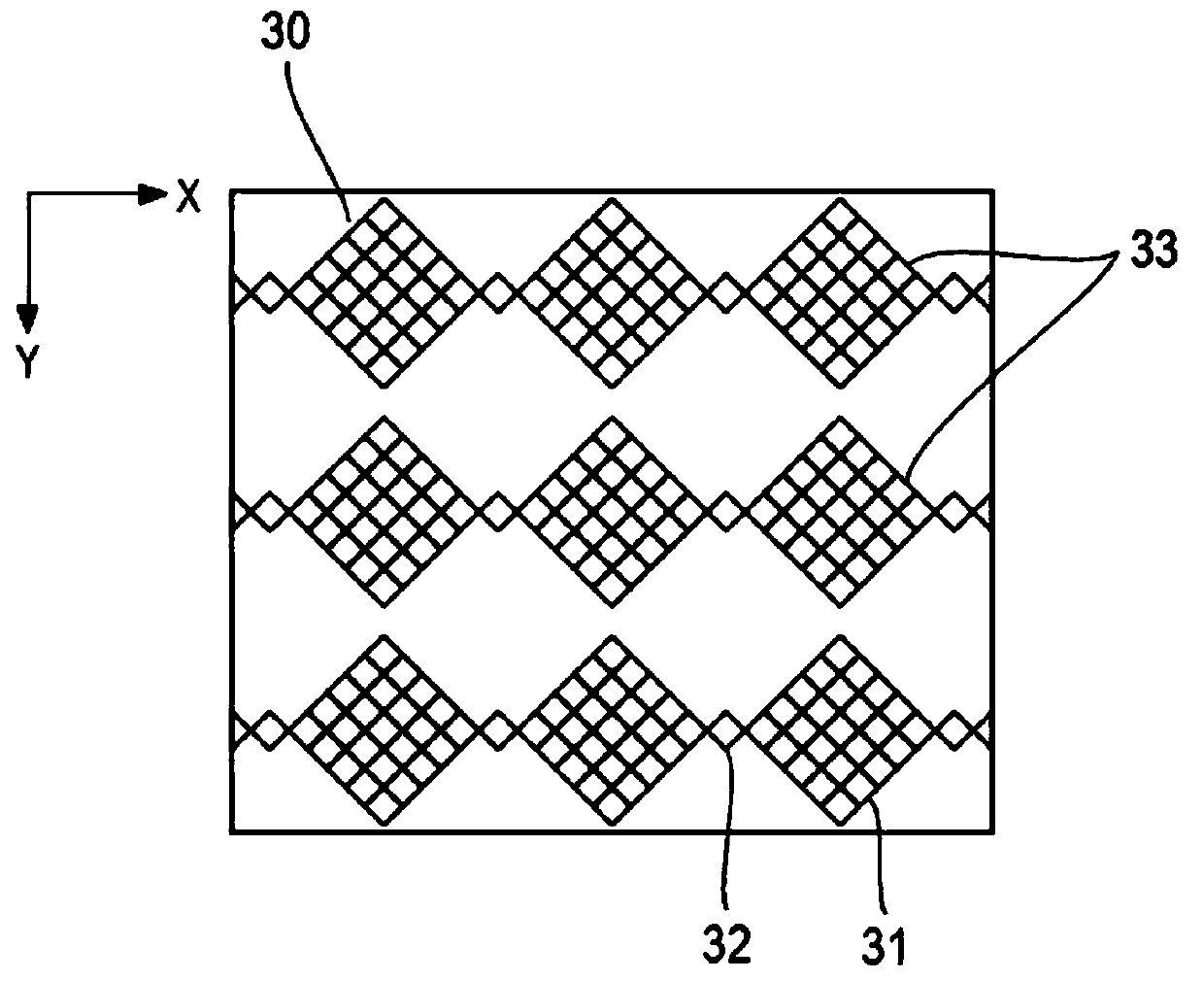

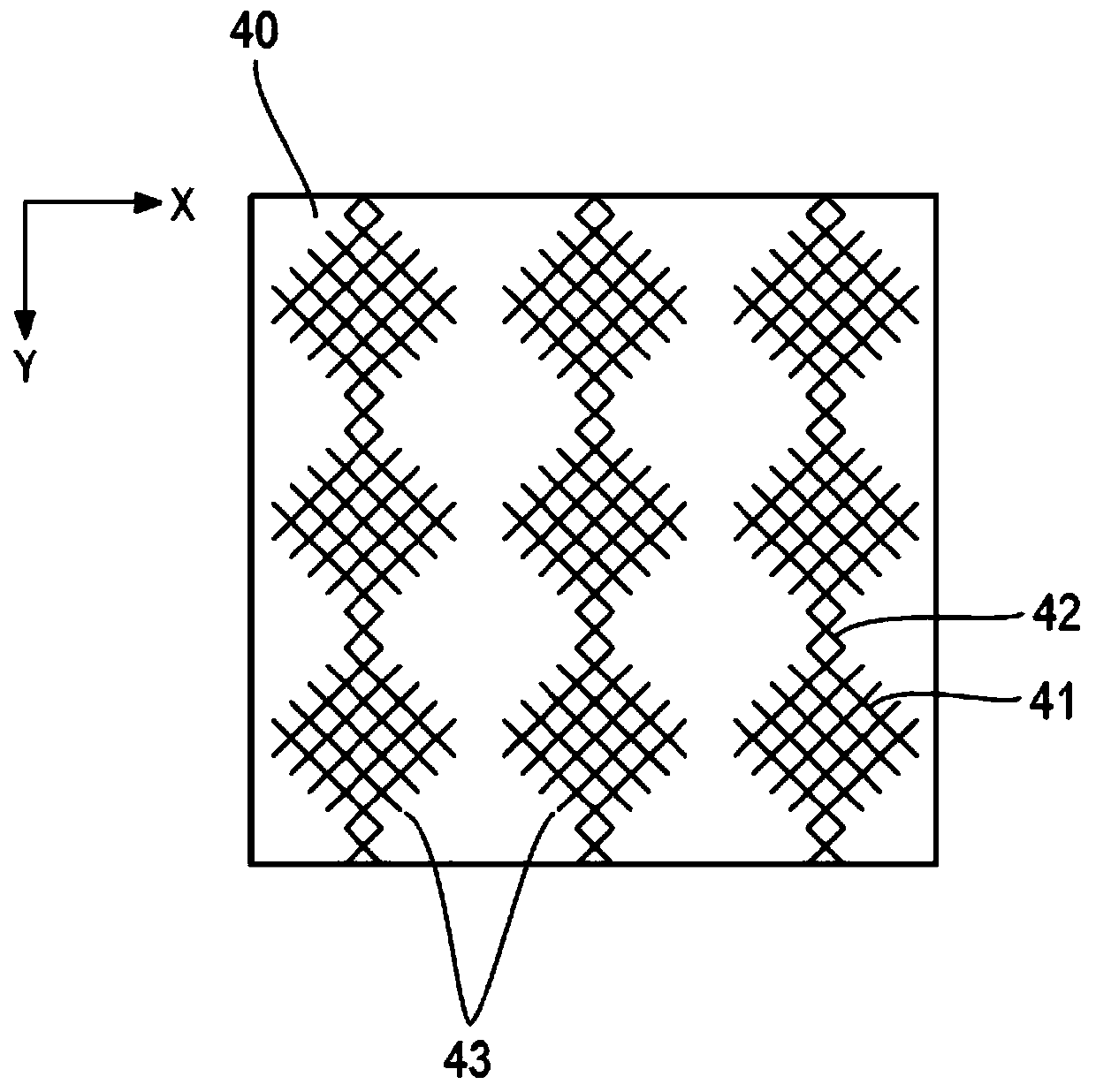

[0034] The touch panel is used in this example with figure 1 The touch panel of the conventional example shown is different in the structure of the external connection terminals formed in the center part of one long side of the base material 10 and the structure in the sensing area 20, and other structures are the same as figure 1 The structures shown are essentially the same. In addition, in Figure 6 The detailed illustration of the structure in the sensing region 20 is omitted in FIG.

[0035] The touch panel has a first conductive layer made of first cured conductive in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com