Spring-based battery anti-vibration and anti-shock mechanism

An anti-shock, battery technology, applied to secondary batteries, battery pack components, circuits, etc., can solve problems such as internal short circuit, explosion, and failure of internal components of lithium-ion batteries, and achieve the effect of reducing damage and preventing explosions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

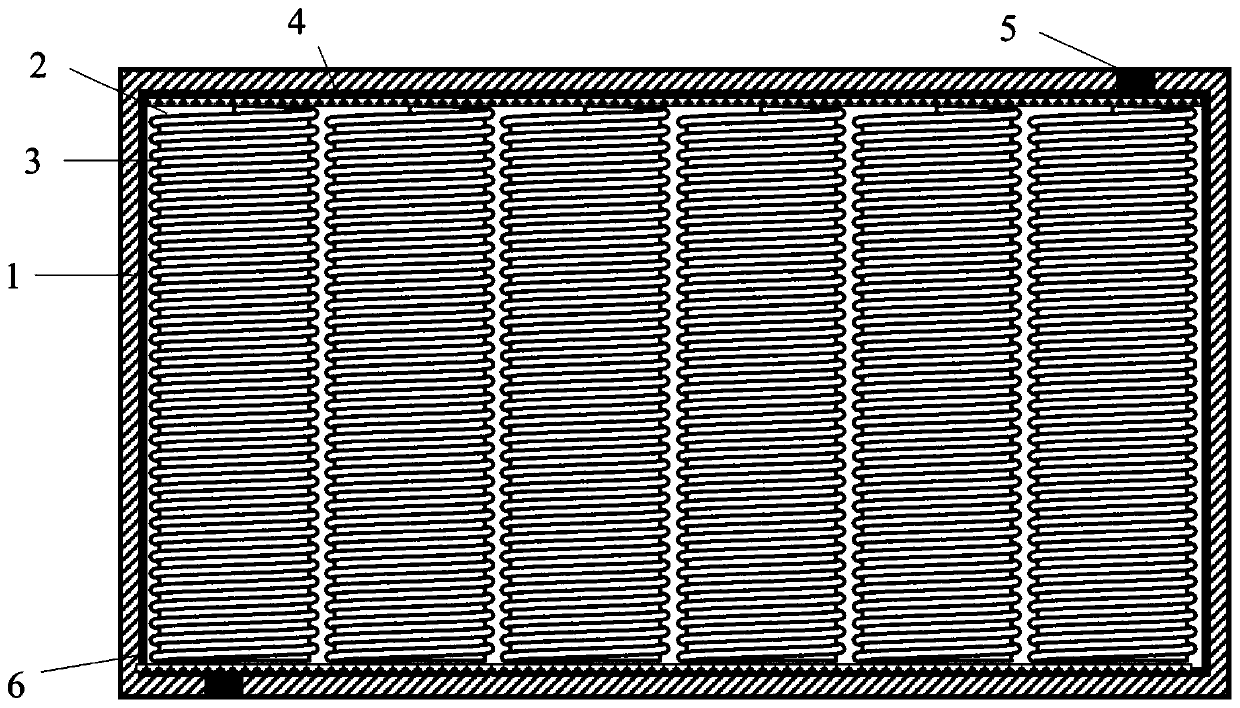

[0019] Such as figure 1 As shown, the spring-based battery shockproof and shockproof mechanism of the present invention includes: a battery box 1 , a spring 2 , a cylindrical lithium-ion battery 3 , a heat-conducting glue 4 , a pressure relief valve 5 and a flame-retardant material 6 .

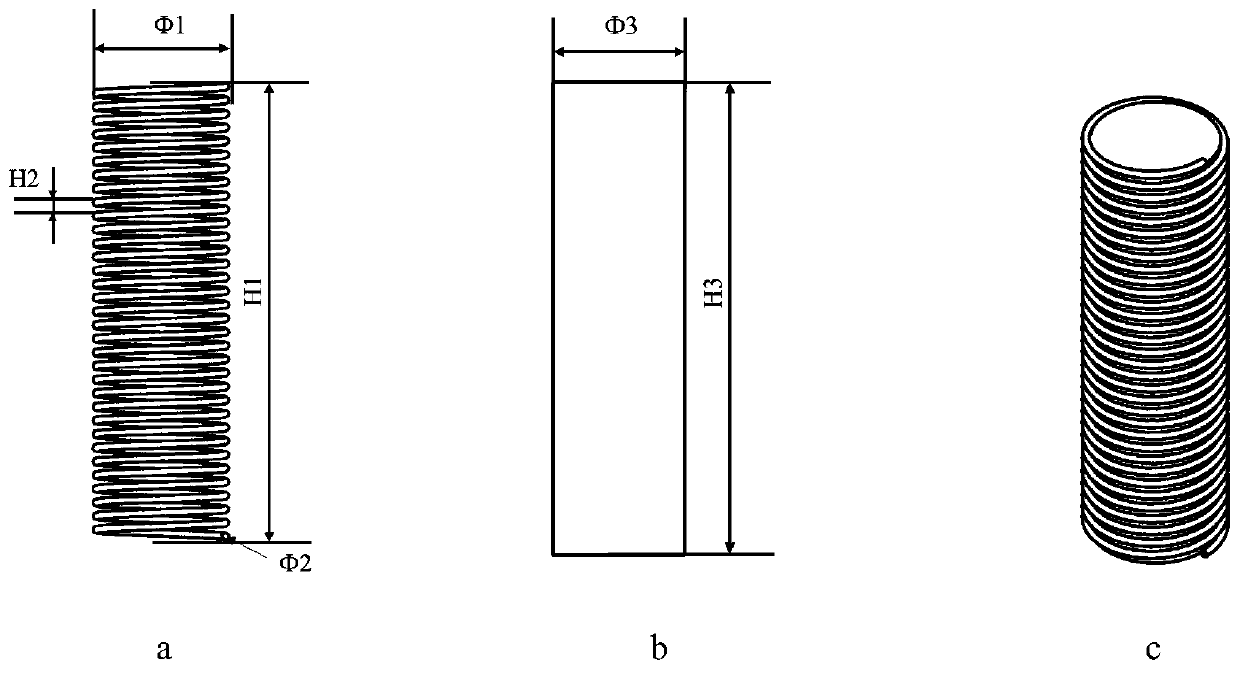

[0020] The cylindrical lithium-ion battery 3 is fixed in the battery box 1 through a thermally conductive glue 4, such as figure 1 shown. The upper and lower ends of the battery box 1 are equipped with a pressure relief valve 5, and the inside of the battery box 1 is coated with a flame retardant material 6. The cylindrical lithium-ion battery in this example is a 18650 nickel-cobalt-aluminum ternary lithium-ion battery. The spring is a steel spring with a thermal conductivity of 100W / (m·k). The size of the spring is designed to be 66cm in height and 18mm in inner diameter according to the size of the 18650 lithium-ion battery. The thermal conductivity of the thermally conductive adhesive i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com