Fiber push-out device based on laminated piezoelectric ceramics and working method thereof

A technology of laminated piezoelectric ceramics and push-out device, which is applied to piezoelectric effect/electrostrictive or magnetostrictive motors, electrical components, generators/motors, etc. Easily affected by inertia, unable to guarantee displacement resolution, etc., to achieve the effect of ensuring accuracy, simple mechanism, and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

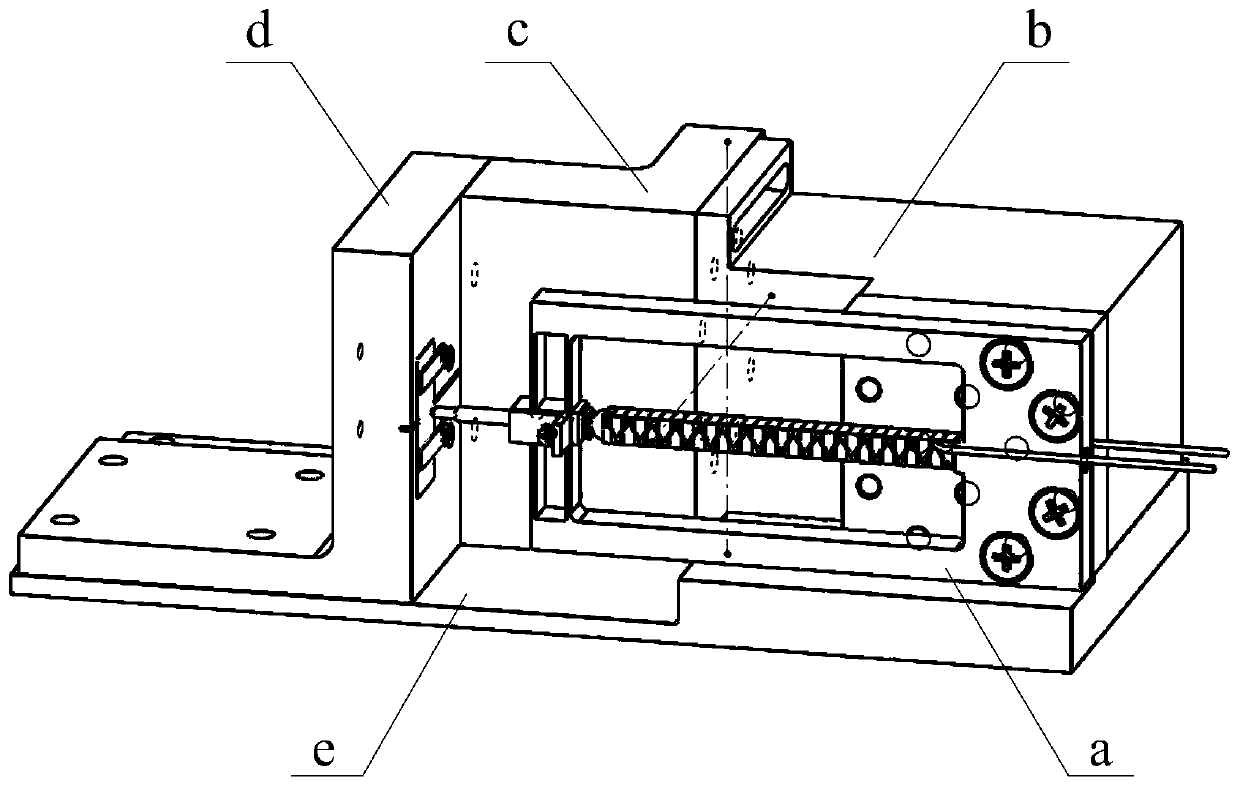

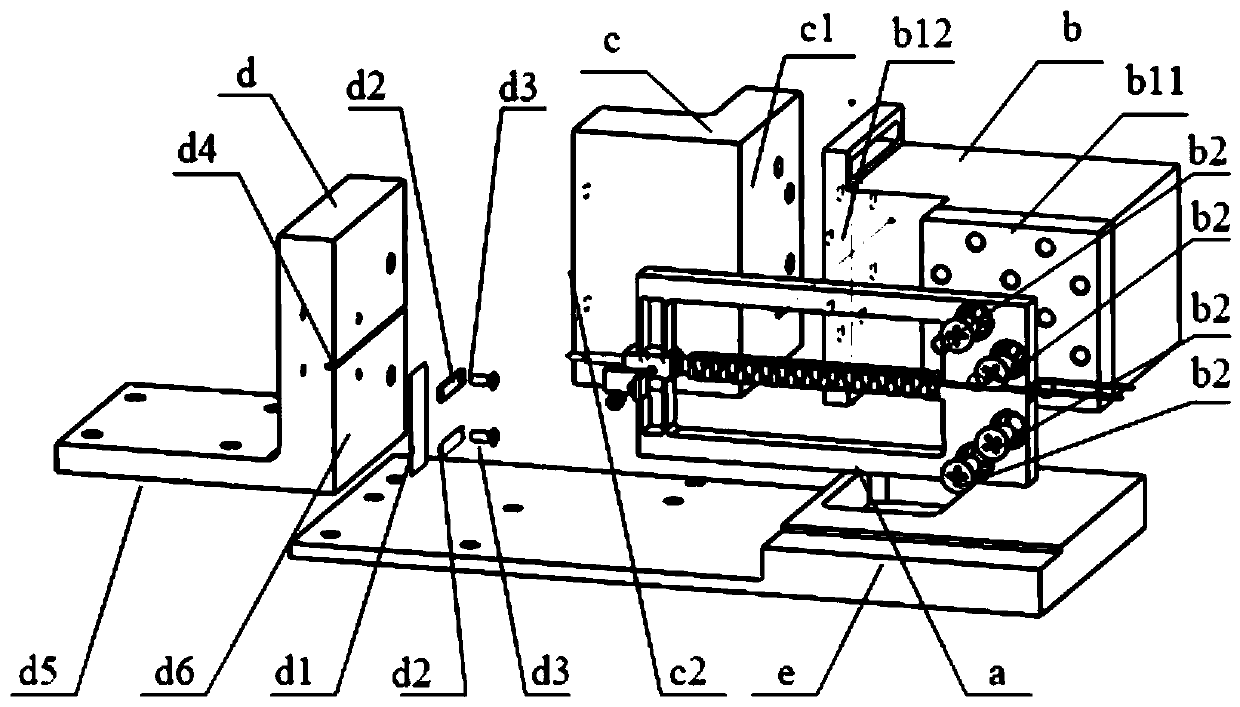

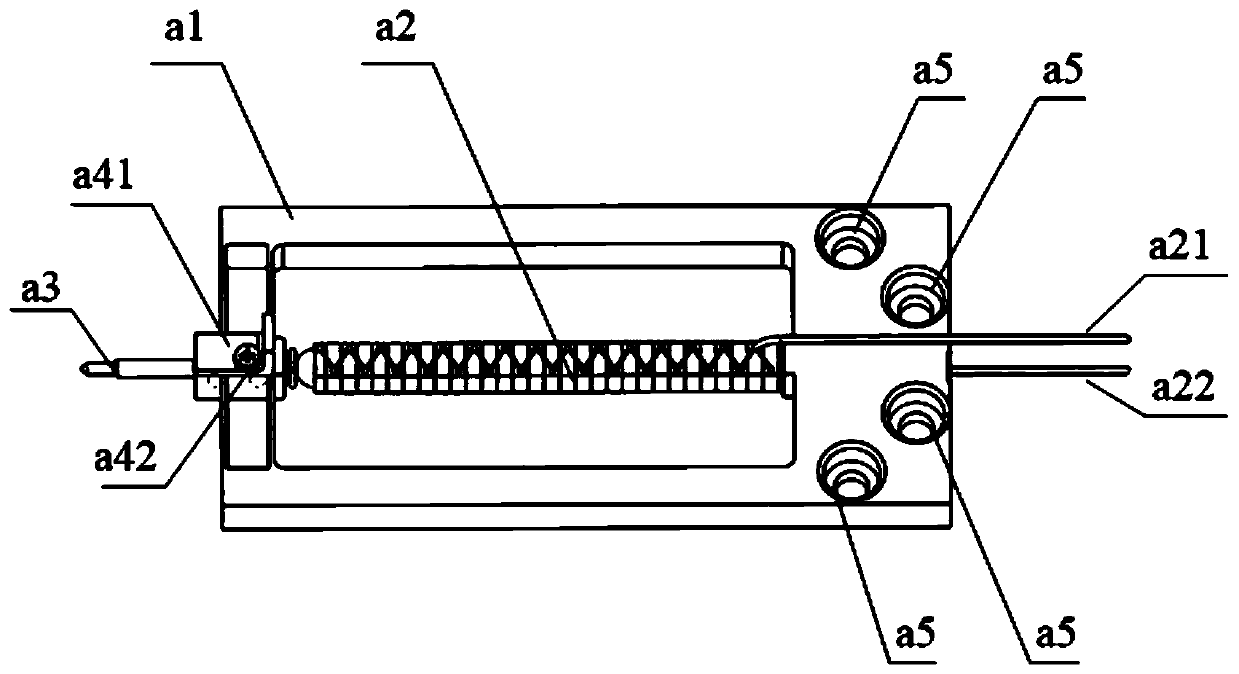

[0030] like Figure 1-2 Shown is a fiber push-out device based on laminated piezoelectric ceramics, including piezoelectric micro-displacement output unit a, manual adjustment micro-motion platform b, L-shaped connecting block Ic, L-shaped connecting block IId, and base e;

[0031] Among them, the L-shaped connecting block IId, the L-shaped connecting block Ic, and the manual adjustment micro-motion platform b are sequentially arranged on the base e, and the L-shaped connecting block IId with an L-shaped longitudinal section is threaded with the base e through the lower mounting surface d5 Fixed connection, the L-shaped connection block Ic with L-shaped cross section is screwed to the L-shaped connection block IId through the installation surface IIc2, and the manual adjustment micro-motion platform b is fixed to the installation surface Ic1 of the L-sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com