A kind of phase change graphene thermal pad, preparation method and application thereof

A heat-conducting gasket, graphene technology, applied in chemical instruments and methods, materials for heat exchange, cooling/ventilation/heating transformation, etc. Problems such as poor thermal conductivity of high-power devices, to achieve the effects of close contact, low thermal resistance, and low production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Please check Figure 1-4 , a preparation method of a phase-change graphene thermal pad of the present embodiment, comprising the steps of:

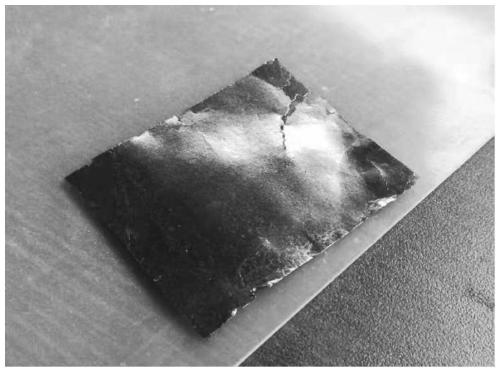

[0027] (1) Expanded graphite at 900°C, packed in a ziplock bag, repeatedly rolled into sheets by a double-roller rolling machine, soaked in GO solution for 2 days, dried in vacuum at 70°C for 24 hours, rolled tightly, and dried at 400°C Annealed in a water vapor atmosphere for 2 hours; the obtained intermediate layer 1 graphite sheet is as figure 2 shown;

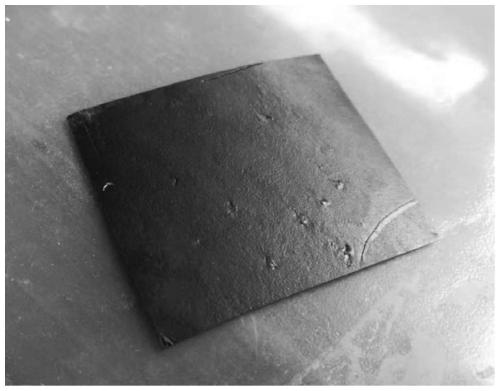

[0028] (2) The mass fraction of expanded graphite at 900°C is 75%, high-density polyethylene 15%, toughening agent POE-g-MAH 5%, and graphene oxide 5% are mixed and hot-pressed into sheets at 200°C to obtain the upper and lower layers of graphite / polymer phase change material sheet (coating layer 2) such as figure 2 shown.

[0029] (3) Take one piece of intermediate layer 1 obtained in step (1), stack the two pieces of cladding layer 2 obtained in step (2), center the gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com