Corn peeling device and method thereof

A technology of corn husks and corn, which is applied to agricultural machinery and tools, applications, harvesters, etc., can solve the problems of high labor cost, heavy hand injury, and low efficiency, so as to ensure food safety, save labor costs, and improve economic efficiency. benefit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

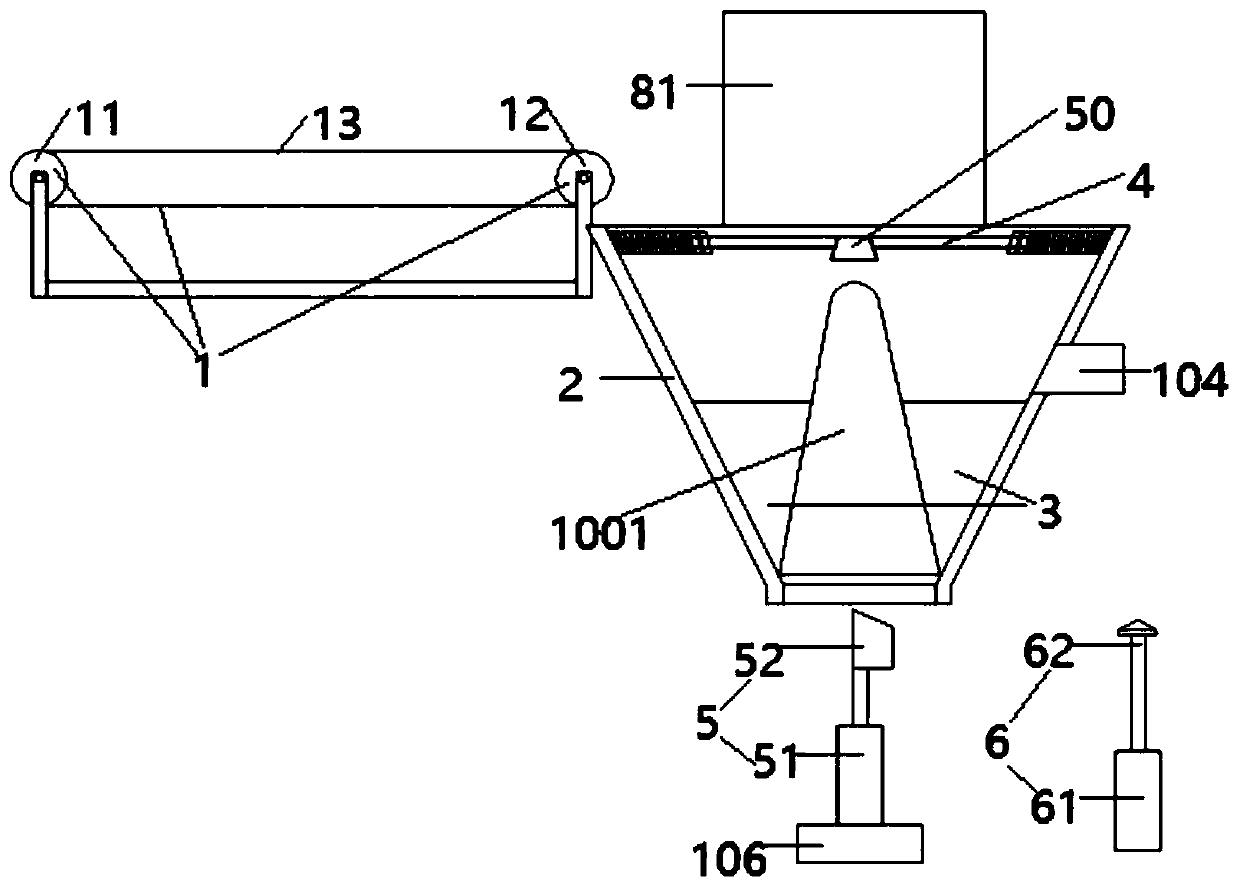

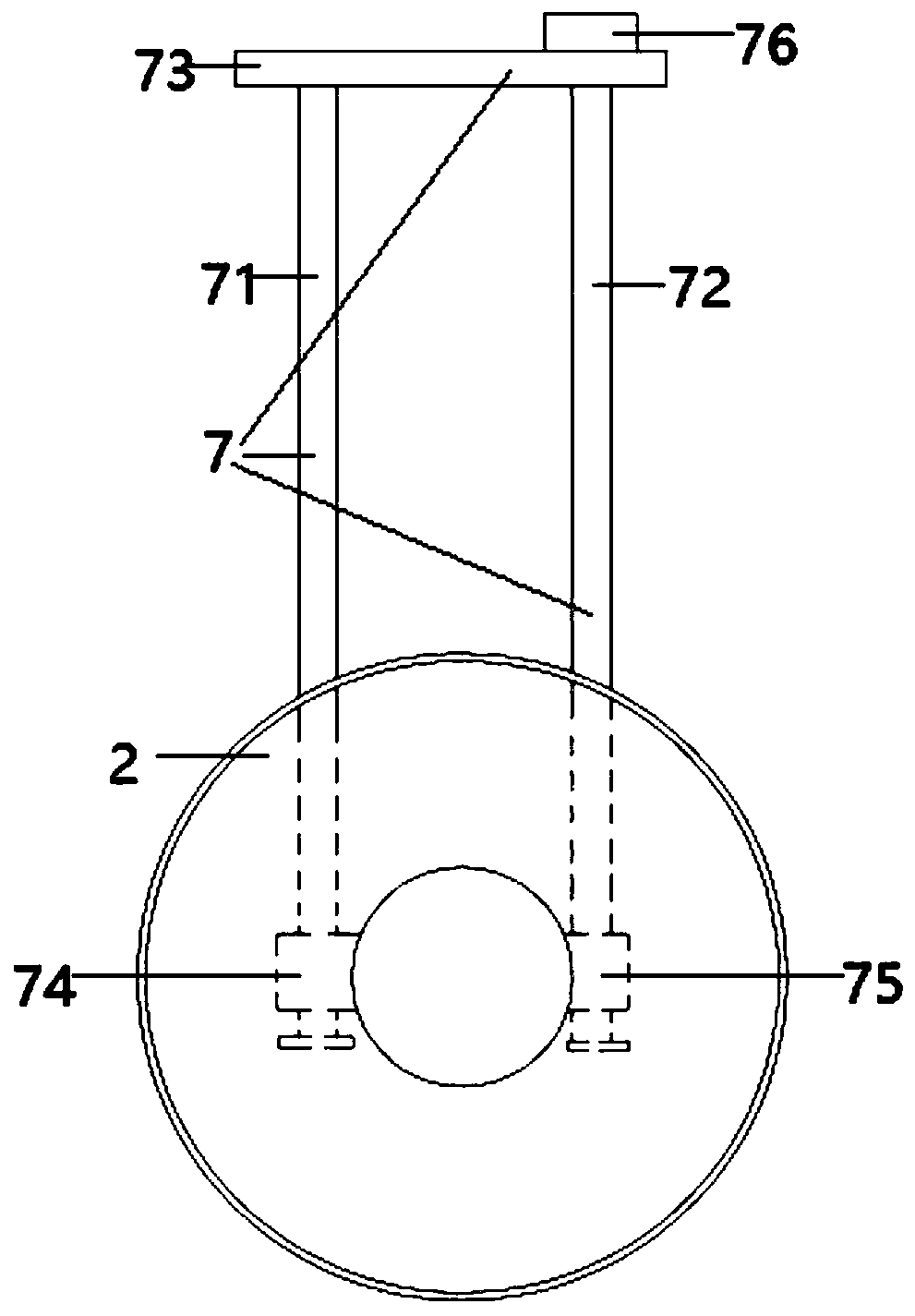

[0038] like figure 1 The shown embodiment is a corn peeling device, comprising a conveyor belt mechanism 1, a conical funnel 2 arranged on the right side of the conveyor belt mechanism, an annular air bag 3 arranged in the lower part of the funnel, and four airbags arranged on the upper edge of the funnel. The horizontal support rods 4 arranged along the upper edge of the funnel, the annular elastic sleeves 50 arranged on the free ends of each horizontal support rod, the cutting mechanism 5 and the push-up mechanism 6 arranged below the funnel are used to drive the funnel to move longitudinally The push-pull mechanism 7; the upper edge of the funnel is provided with a corn collection channel 8 and a toggle mechanism 9, the lower end of the corn collection channel is connected with the storage box 10, the annular air bag is connected with the air pump 101, the annular air bag is provided with a solenoid valve 102, and the cutting mechanism It includes a vertically placed first ...

Embodiment 2

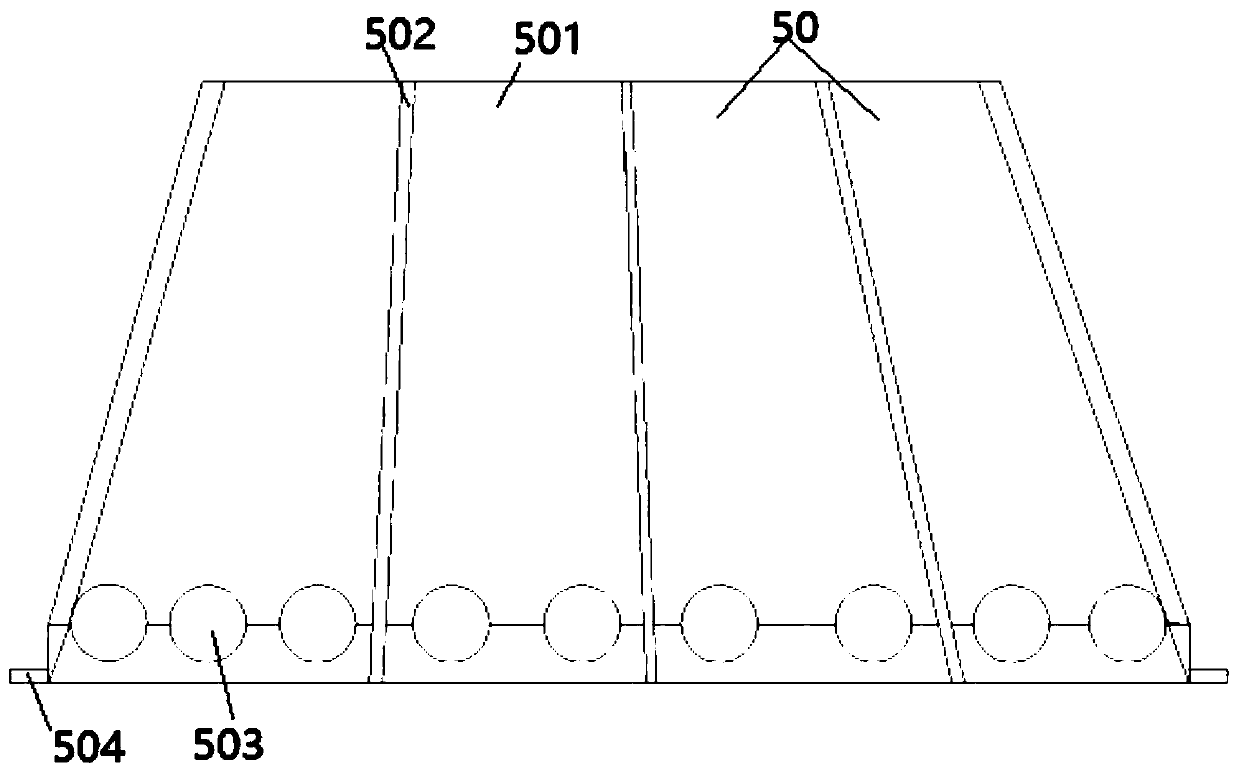

[0056] Embodiment 2 includes all structure and method parts of embodiment 1, such as figure 2 As shown, the annular elastic sleeve is in the shape of a conical tube with a large opening at the lower end; the annular elastic sleeve includes 8 connecting plates 501 arranged in a ring, and the adjacent connecting plates are connected by elastic bands 502, each connecting plate A plurality of balls 503 are arranged on the inner side of the edge, and a plurality of cutting knives 504 arranged at intervals are arranged on the outer side of the lower edge of each connecting plate, and the blade of each cutting knife is downward.

[0057] The ring-shaped elastic sleeve pushes the corn husk away and is replaced by the following steps:

[0058] Each cutter divides the corn husks into strips, and each connecting plate pushes the corn husks away to separate the corn husks from the cobs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com