System and method for controlling lifting spray arm of dish washer based on three-dimensional scanning

A technology of three-dimensional scanning and dishwasher, which is applied to the washing machine/washing machine of tableware, the parts of washing machine/rinsing washing machine of tableware, household cleaning device, etc. Washing, tableware cannot be stored for a long time, etc., to achieve the effect of improving cleaning efficiency and improving practical experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

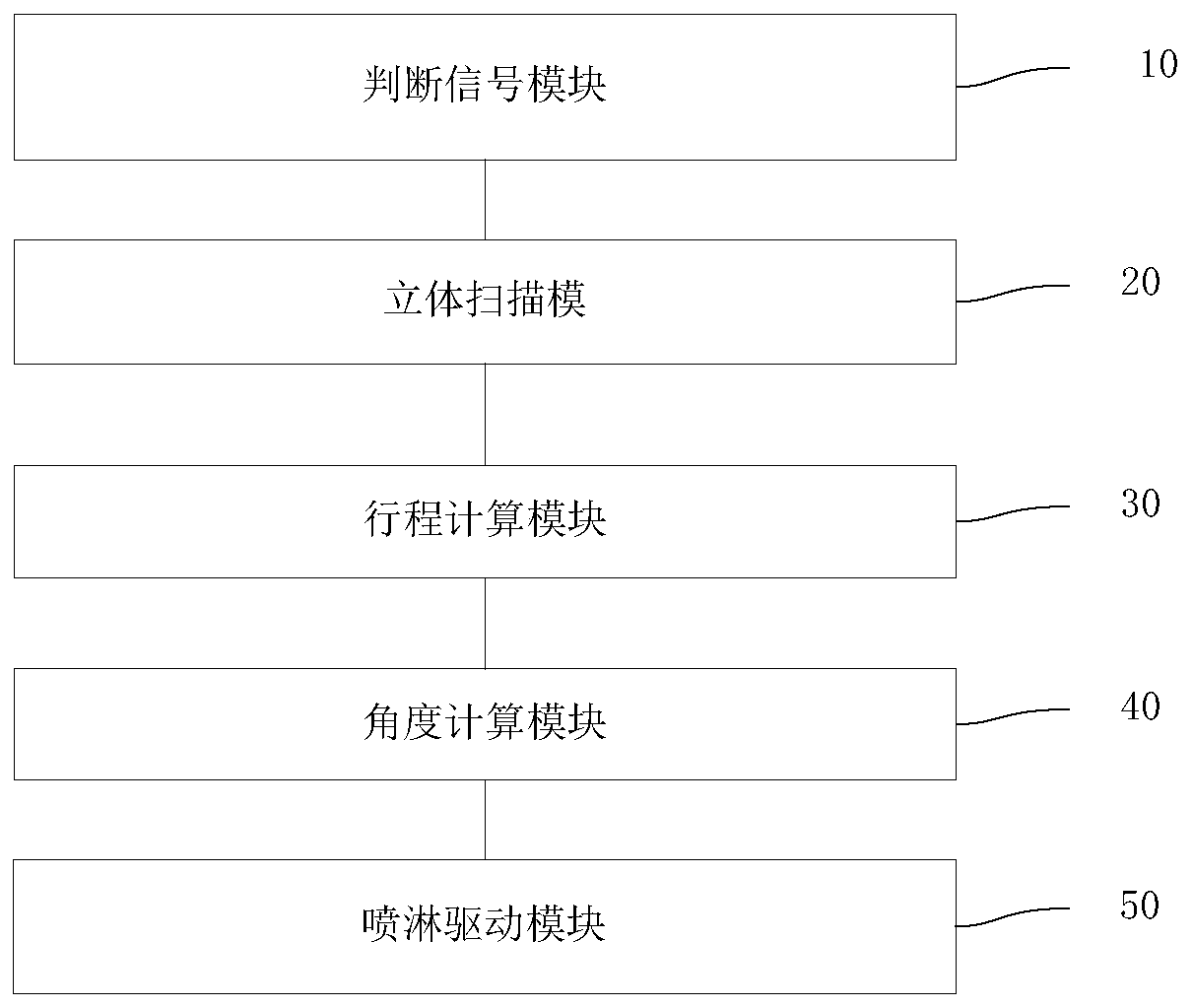

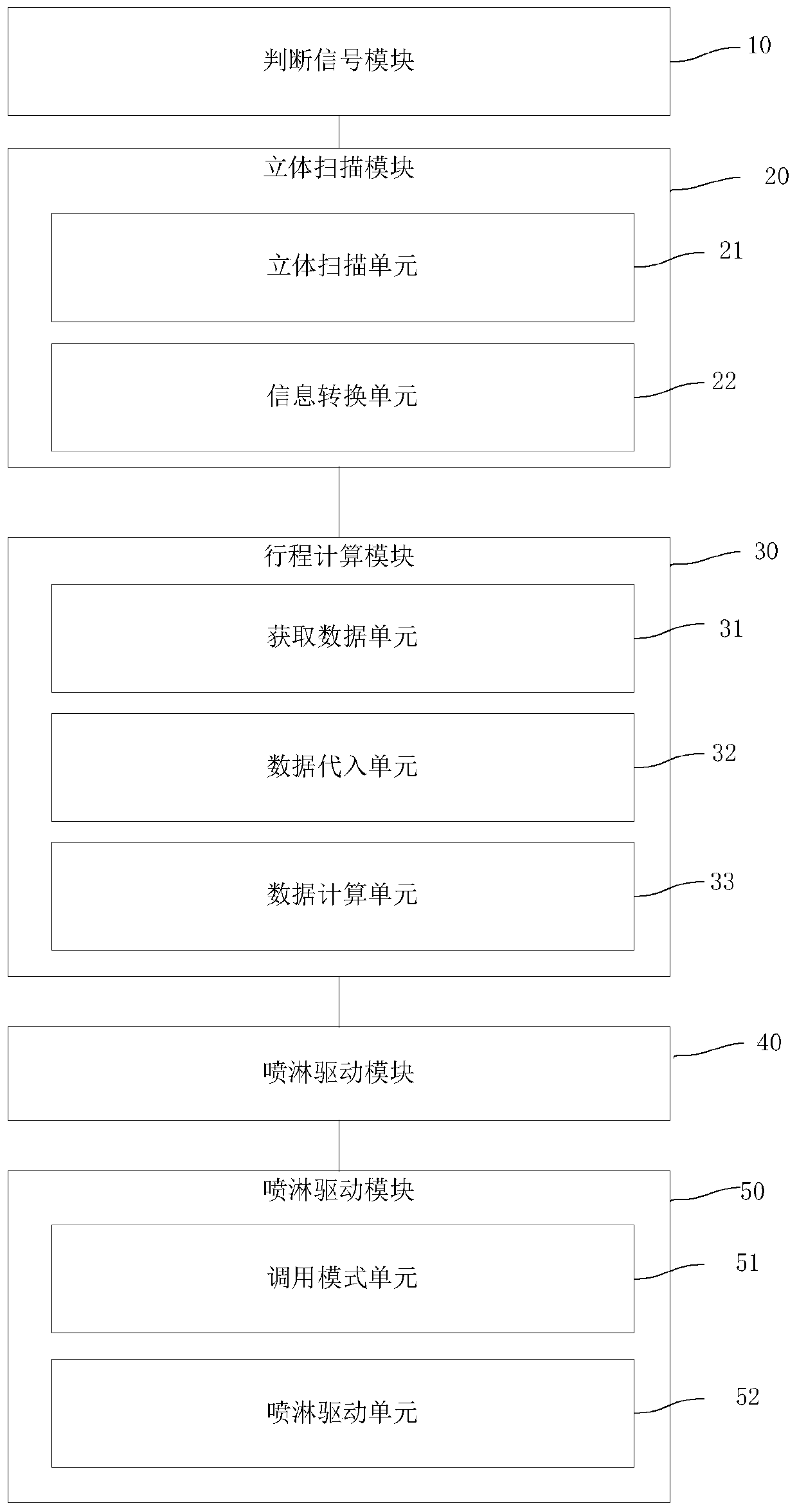

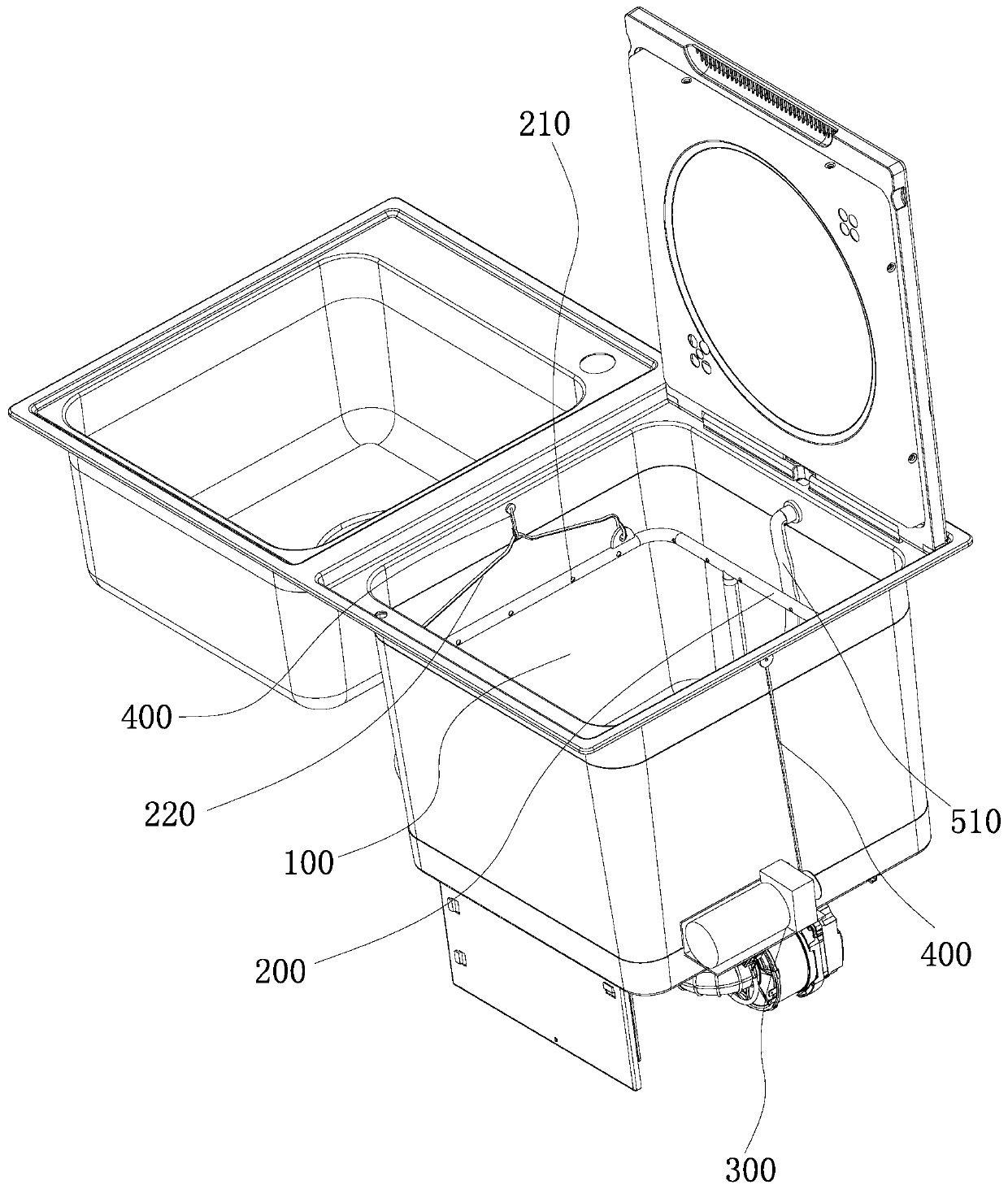

[0057] This implementation provides a system for controlling the lifting and lowering spray arms of dishwashers based on three-dimensional scanning, such as Figure 1 to Figure 3 As shown, the system includes:

[0058] Judging signal module, used for judging whether to receive the dishwasher cleaning start signal;

[0059] The three-dimensional scanning module is used to perform three-dimensional scanning on the object to be washed in the dishwasher after receiving the washing start signal of the dishwasher, and save the result of the three-dimensional scanning;

[0060] The stroke calculation module is used to calculate the spray stroke corresponding to the lifting spray arm of the dishwasher according to the preset spray stroke algorithm according to the result of the three-dimensional scanning;

[0061] The angle calculation module is used to calculate the spray angle corresponding to the lifting spray arm of the dishwasher according to the preset spray angle algorithm acc...

Embodiment 2

[0091] This embodiment provides a method for controlling the lifting and lowering spray arms of dishwashers based on three-dimensional scanning, such as Figure 4 to Figure 5 , the method provided in this implementation based on three-dimensional scanning to control the lifting and lowering spray arm of the dishwasher includes the steps:

[0092] S1: judging whether a dishwasher cleaning start signal is received;

[0093] S2: If yes, perform a three-dimensional scan on the object to be washed in the dishwasher, and save the result of the three-dimensional scan;

[0094] S3: Calculate the spray stroke corresponding to the lifting spray arm of the dishwasher according to the preset spray stroke algorithm according to the result of the three-dimensional scanning;

[0095] S4: Calculate the spray angle corresponding to the lifting spray arm of the dishwasher according to the preset spray angle algorithm according to the result of the three-dimensional scanning;

[0096] S5: Acco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com