Mining modularized dry-type dedusting system and dedusting method

A dry dust removal and modular technology, which is applied to chemical instruments and methods, separation methods, dust prevention, etc., can solve problems such as time-consuming and labor-intensive, complicated operation procedures, and limitations of dry dust removal equipment, so as to improve the dust removal effect and reduce cleaning. Gray steps, the effect of reducing work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

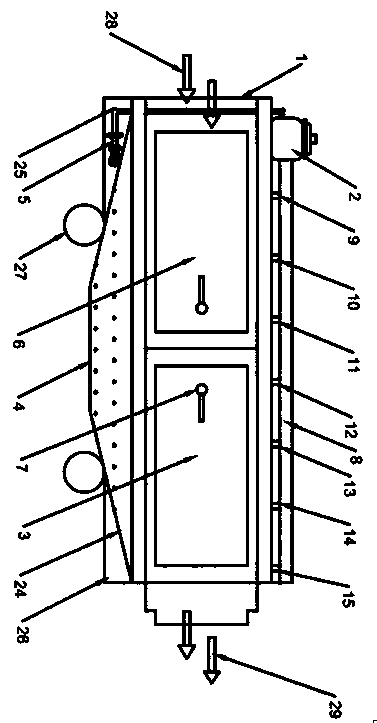

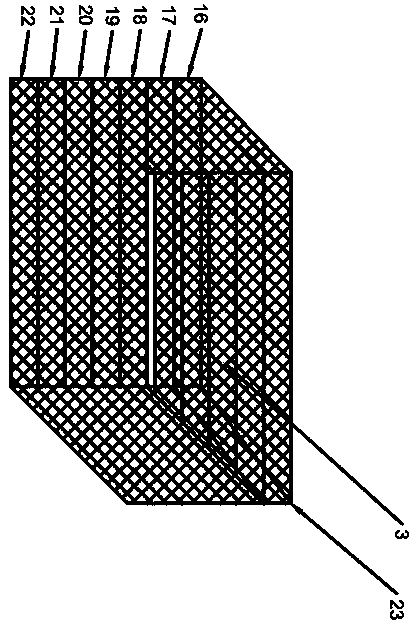

[0015] Such as figure 1 As shown, a modular dry dust removal system for mines includes a filter box 1, a pneumatic blowing device 2, a soft metal filter device 3, an automatic ash unloading device 4 and a percussion hammer 5;

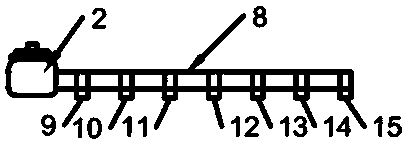

[0016] The filter box 1 is provided with a soft metal filter device 3, and the top of the filter box 1 is provided with a pneumatic blowing device 2. One end of the pneumatic blowing device 2 is connected to the air pipe I8, and one end of the pneumatic blowing device 2 is connected to the air pipe II25. The air duct II 25 is connected to the percussion hammer 5; the automatic ash unloading device 4 is installed under the filter box 1.

[0017] The top of the filter box 1 is provided with a pneumatic blowing device 2, the air outlet of the pneumatic blowing device 2 is connected to the air pipe I8, and the bottom of the air pipe I8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com