Intelligent dust removal and explosion-proof and waste gas purification device for casting industry

An exhaust gas purification device and industry technology, applied in foundry equipment, manufacturing tools, metal processing equipment, etc., to reduce air volume requirements, reduce cleaning and maintenance costs, and improve integrity and safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

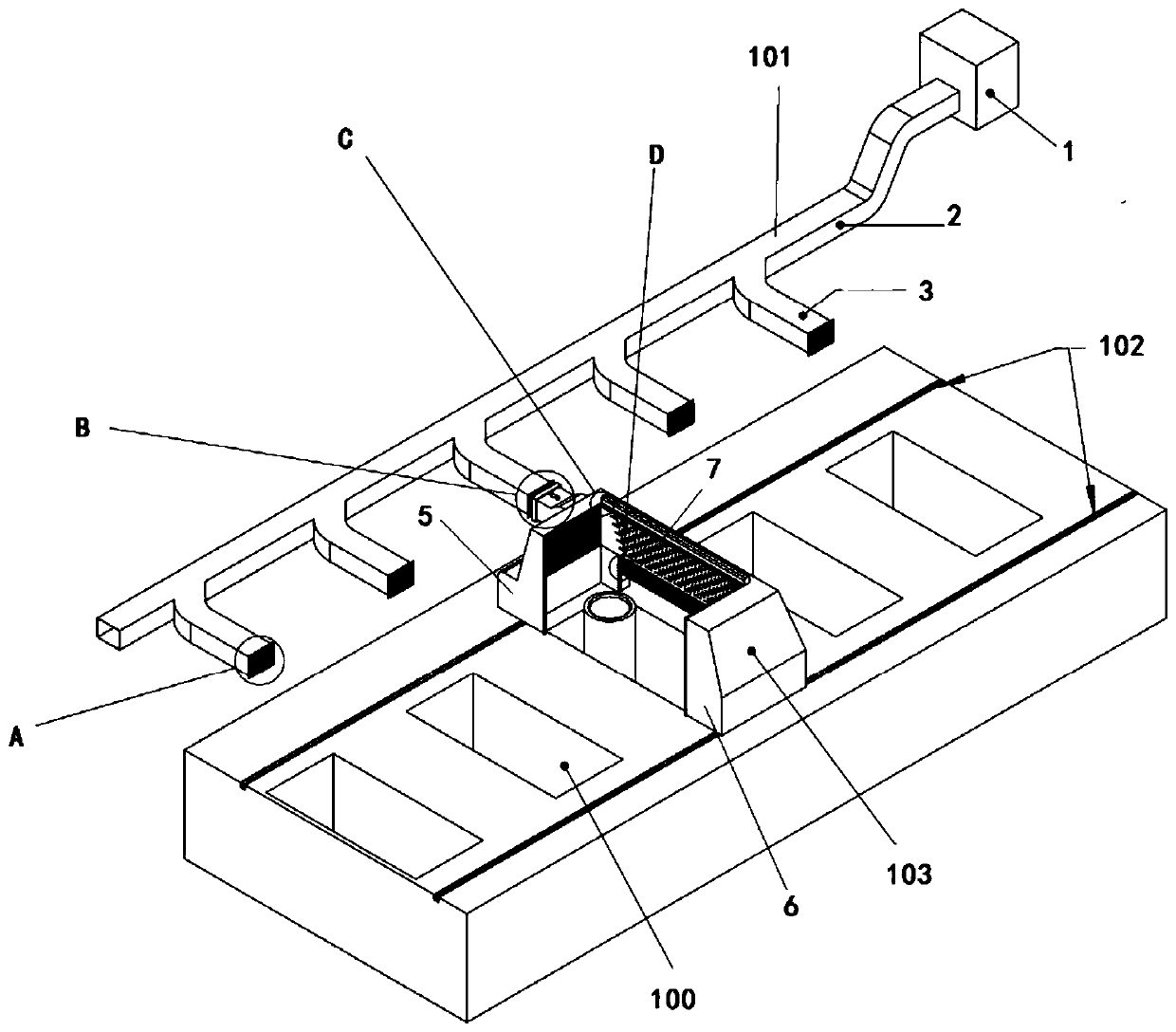

[0022] Such as Figures 1 to 5 As shown, an intelligent dust removal and explosion-proof exhaust gas purification device in the foundry industry is used to collect dust and exhaust gas generated by multiple pouring pits 100 in the workshop. It includes a collection system 101 installed on one side of the workshop, along the pouring pit A pair of guide rails 102 arranged on both sides, and an absorption room 103 that can move along the guide rails and collect dust and waste gas generated in the pouring pit.

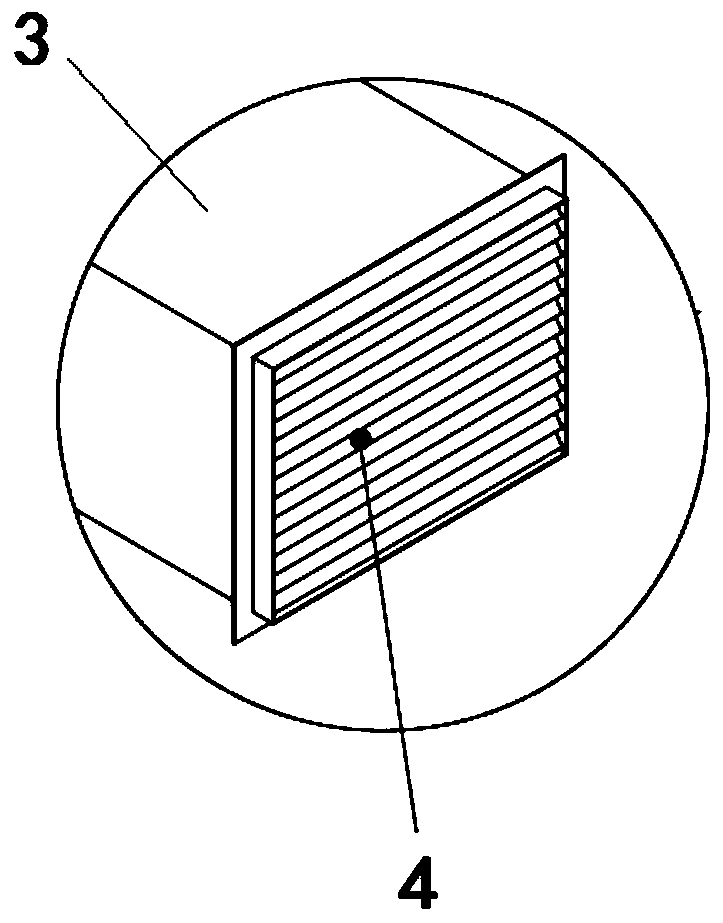

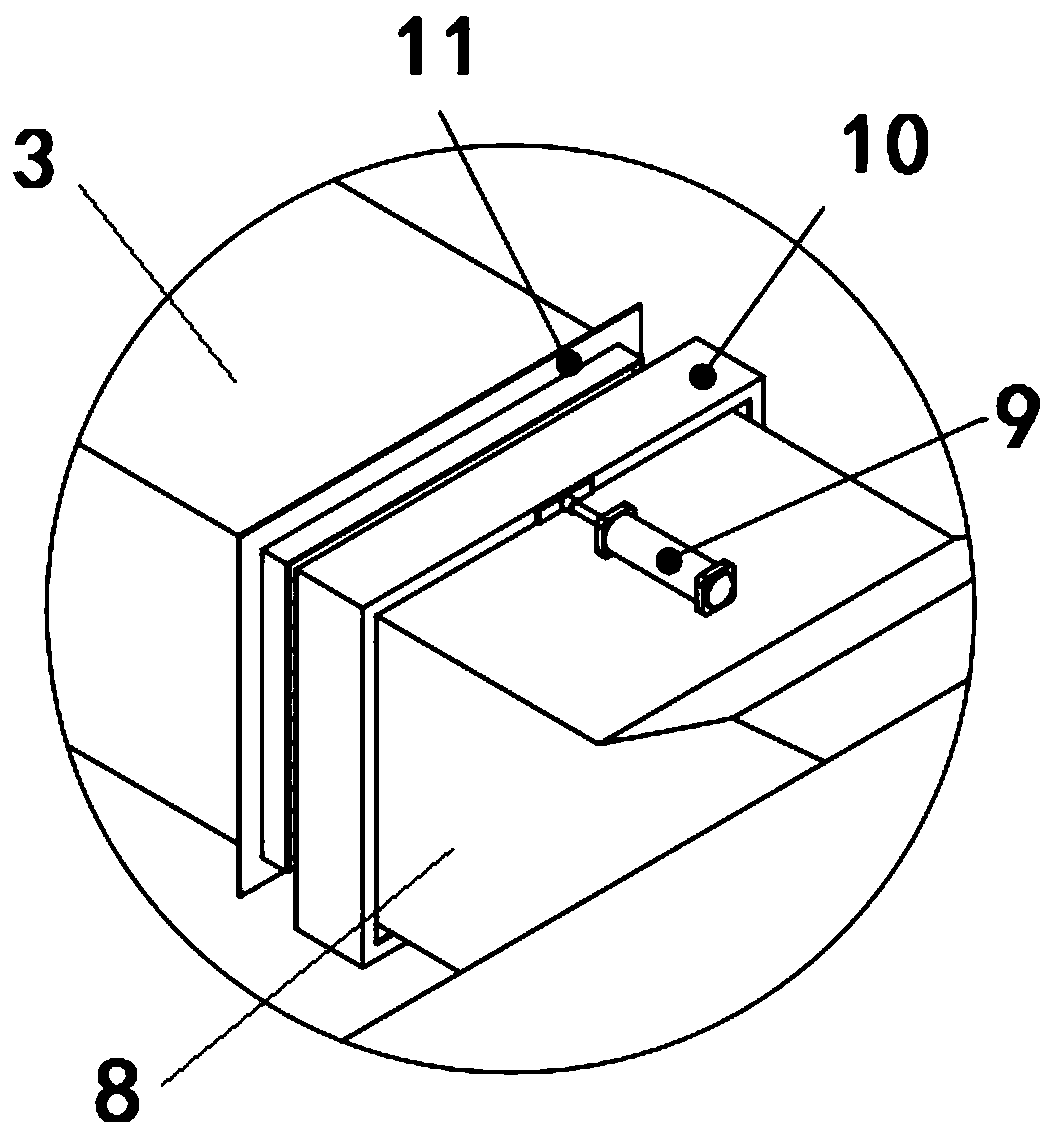

[0023] Wherein, the collection system 101 includes: a fan 1 providing negative pressure air source, a main pipeline 2 connected with the fan, and several branch pipelines 3 respectively corresponding to multiple pouring pits and communicating with the main pipeline.

[0024] Fan blades 4 are also provided on the end nozzles of the branch pipes 3 . When pouring, the fan blades are automatically opened, and the fan blades are automatically closed when the pouring operation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com