Robot operation trajectory acquisition method based on line laser sensor

A laser sensor and robot technology, applied in the field of robots, can solve the problems of inconsistent line direction, low efficiency, unstable processing quality, etc., and achieve the effect of improving automation level and improving operation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to make the technical solutions and advantages of the present invention clearer, the implementation method of the present invention will be further described below in conjunction with the accompanying drawings.

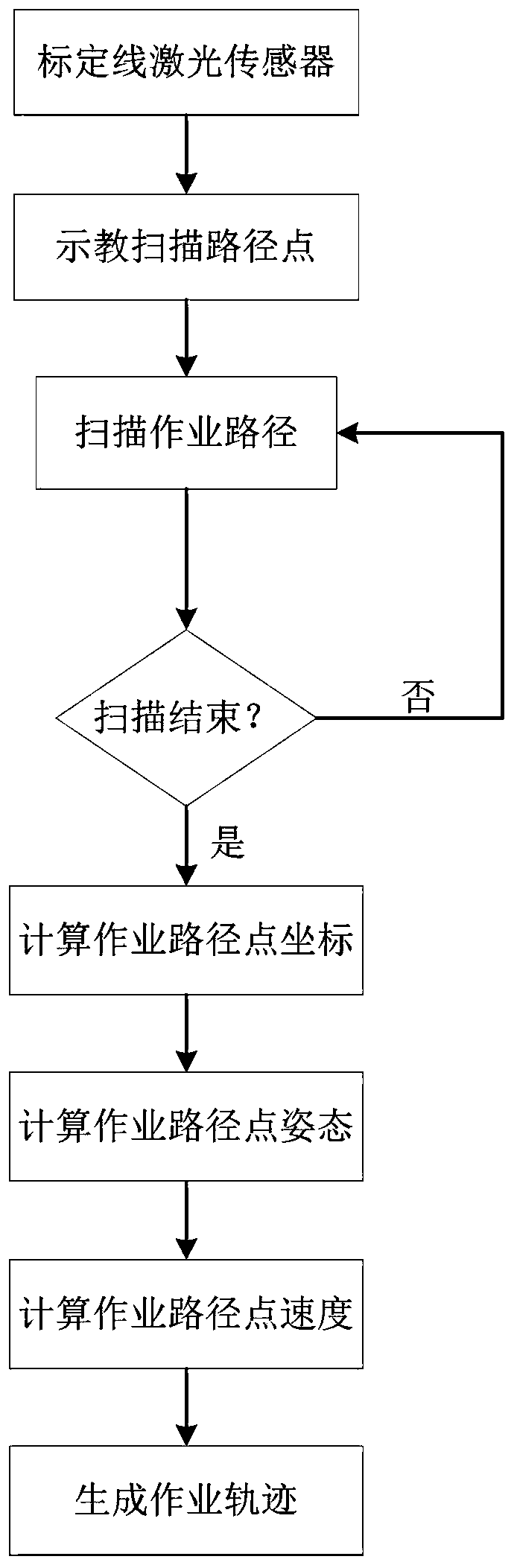

[0043] combine Figure 1-4 , a method for obtaining robot operation trajectory based on a line laser sensor, taking a certain high-grade leather bag sewing process as an example, comprising the following steps:

[0044] (1) Install the line laser sensor at the end of the robot through the end flange and calibrate the hand-eye relationship matrix between the outgoing line laser sensor and the coordinate system of the robot end flange;

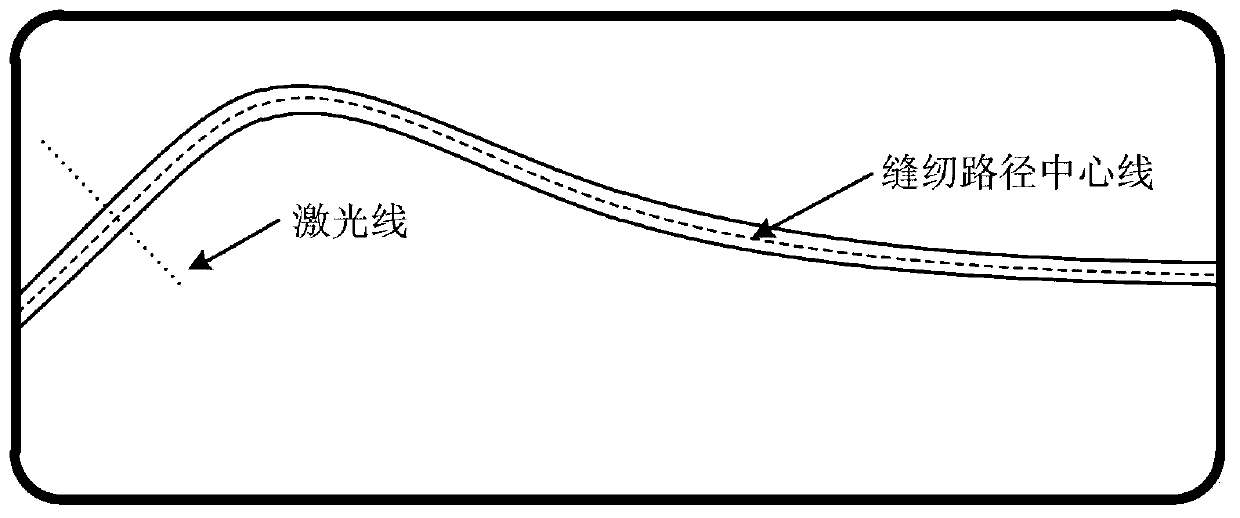

[0045] (2) The scanning trajectory of the manual teaching line laser sensor requires that on the scanning trajectory, each laser line intersects with the working path, and try to ensure that the laser line is perpendicular to the sewing path during the scanning process;

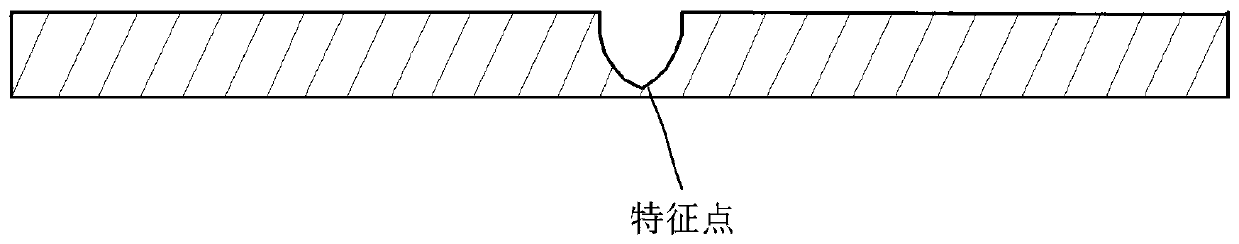

[0046] (3) After the online laser sensor moves a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com