Roller and fabrication method thereof

A manufacturing method and technology of shielding parts, which are applied in the direction of anodizing, coiling strips, thin material processing, etc., can solve the problems of sharp burrs on the roller surface, damage to the surface smoothness of the conveying roller, damage to the surface of the substrate, etc., to improve safety. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

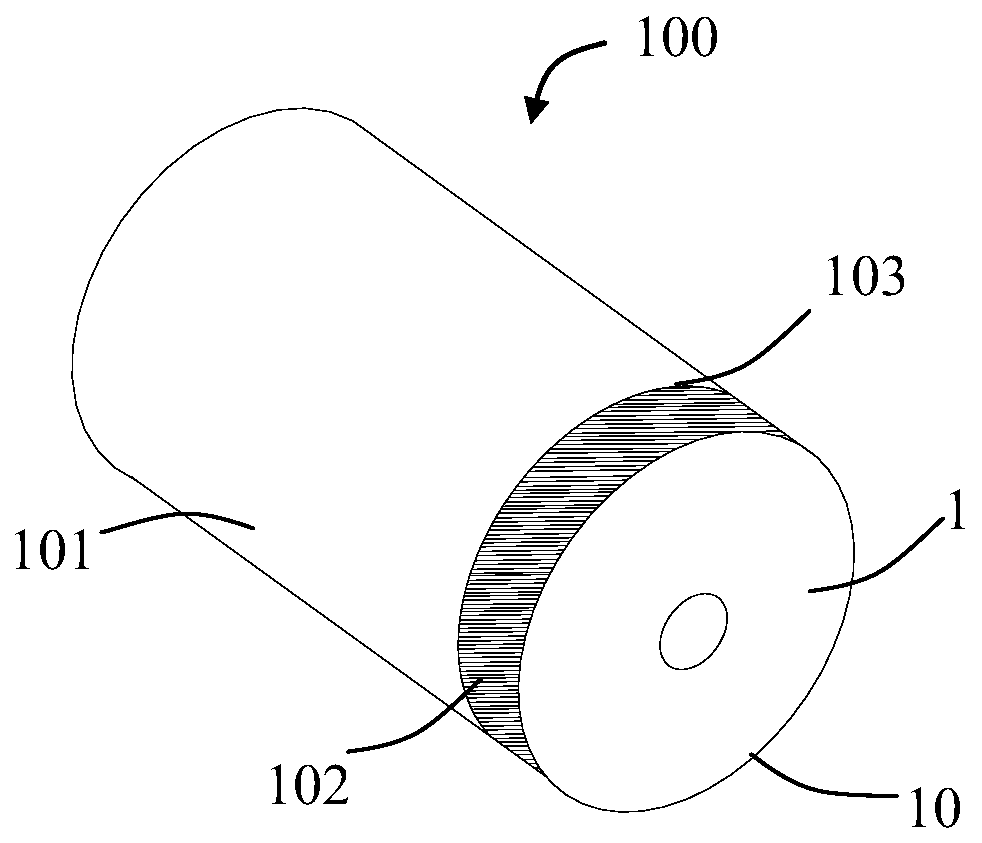

[0027] Please refer to figure 1 As shown, the present invention discloses a roll 100, which is a transport roll used in a winder (not shown) for transporting substrates. The roller 100 includes a body portion 1 and an outer surface 10 of the body portion 1 . The outer surface 10 is divided into a first part 101 and a second part 102 with different colors, and a mark extending around the radial direction of the roller 100 is formed at the junction of the first part 101 and the second part 102 Line 103.

[0028] In the first embodiment of the present invention, the first part 101 of the roller 100 may be a first part 101 with a first color formed by anodic oxidation to form an oxide layer and then dyed, and the second part 102 is only formed by The second part 102 having a second color after being dyed to form a dyed layer, the oxide layer is different in color from the dyed layer, and the marking line 103 is formed at the junction of the oxide layer and the dyed layer.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com