Eucryptite microcrystal glass and preparation method thereof

A technology of glass-ceramics and eucryptite, which is applied in the field of eucryptite glass-ceramics and its preparation, can solve the problems of low utilization rate of eucryptite and high production cost of eucryptite glass-ceramics, and achieve good environmental resistance , Promote further development, excellent performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

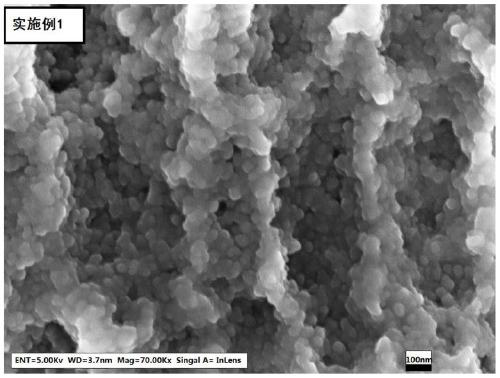

Embodiment 1

[0029] A kind of eucryptite glass-ceramic, by weight, the raw material of eucryptite glass-ceramic comprises: eucryptite: 67 parts, lepidolite: 2 parts, quartz sand: 20 parts, alumina: 2 parts, oxide Zirconium: 1.98 parts, titanium oxide: 2.75 parts, talc: 0.3 parts, barium carbonate: 1.91 parts, antimony trioxide: 0.50 parts, zinc oxide: 1 part.

[0030] Wherein, by weight percentage, the chemical composition of eucryptite includes: Li 2 O: 6.14%, Al 2 o 3 : 25.73%, SiO 2 : 63.74%, Na 2 O and K 2 Total O: 2.2%, TiO 2 , CaO, MnO and Fe 2 o 3 The total ≤ 2%, the loss on ignition and the remaining trace elements ≤ 1.5%; by weight percentage, the chemical composition of lepidolite includes: Li 2 O: 2.78%, Al 2 o 3 : 24.94%, SiO 2 : 54.41%, Na 2 O: 1.69%, K 2 O: 6.21%, F: 1.92%, TiO 2 , CaO, MnO and Fe 2 o 3 Total ≤ 2%, loss on ignition and residual trace elements ≤ 1.5%.

[0031] In terms of weight percentage, the corresponding oxide composition in the glass batc...

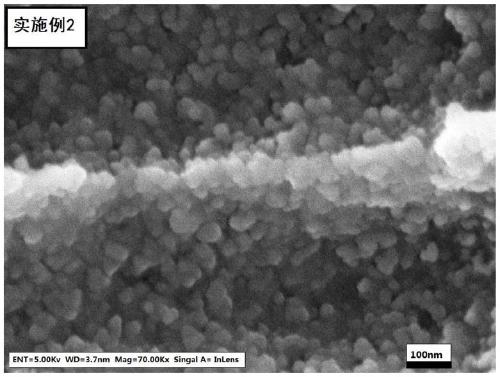

Embodiment 2

[0045] The difference between this embodiment and Embodiment 1 is that, in parts by weight, the raw materials of eutcryptite glass-ceramic include: eutcryptite: 62.61 parts, lepidolite: 3.25 parts, quartz sand: 23.65 parts, alumina: 3.36 parts , soda ash: 0.12 parts, zirconia: 1.98 parts, titanium oxide: 2.75 parts, talc: 0.5 parts, barium carbonate: 1.92 parts, antimony trioxide: 0.50 parts, zinc oxide: 1 part.

[0046] In terms of weight percentage, the corresponding oxide composition in the glass batch prepared from the above raw materials is: Li 2 O: 3.85%, Na 2 O: 1.22%, Al 2 o 3 : 0.25%, SiO 2 : 64.64%, K 2 O: 0.28%, TiO 2 : 2.78%, BaO: 1.49%, Sb 2 o 3 : 0.5%, ZnO: 1.00%, Zr 2 O: 2.00%, P 2 o 5 , MgO, and F total: 0.8%, other oxides with less content (Fe 2 o 3 +MnO+CaO) total: 0.65%.

[0047] The difference between the preparation method of the above-mentioned eucryptite glass-ceramic and that of Example 1 is that when the raw materials in step 1) are mixed,...

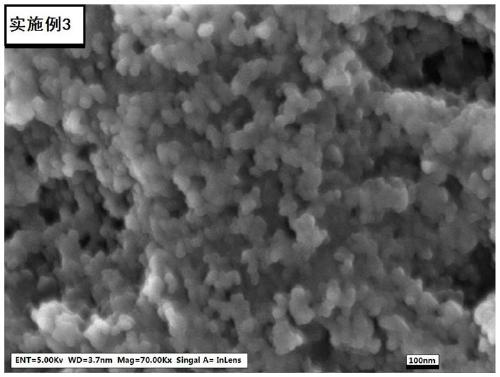

Embodiment 3

[0057] The difference between this embodiment and Embodiment 1 is that, in parts by weight, the raw materials of eutcryptite glass-ceramic include: eutcryptite: 57.01 parts, lepidolite: 6.23 parts, quartz sand: 28.42 parts, alumina: 5.26 parts , soda ash: 0.25 parts, zirconia: 1.98 parts, titanium oxide: 2.77 parts, talc: 0.45 parts, barium carbonate: 1.92 parts, antimony trioxide: 0.50 parts, zinc oxide: 1 part.

[0058] In terms of weight percentage, the corresponding oxide composition in the glass batch prepared from the above raw materials is:

[0059] Li 2 O: 3.51%, Na 2 O: 1.23%, Al 2 o 3 : 20.11%, SiO 2 : 64.96%, K 2 O: 0.28%, TiO 2 : 2.80%, BaO: 1.50%, Sb 2 o 3 : 0.50%, ZnO: 1.00%, Zr 2 O: 2.00%, P 2 o 5 , F and MgO total: 0.78%, other less oxides (Fe 2 o 3 , MnO and CaO) a total of 0.65%

[0060] The difference between the preparation method of the above-mentioned eucryptite glass-ceramics and that of Example 1 is that when the raw materials in step 1) a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com