Low-gloss, high-performance and thin-walled polypropylene composite material and preparation method thereof

A composite material and polypropylene technology, applied in the field of polymer modification and processing, can solve the problems of high gloss of parts, high gloss of mold parts, affecting the comfort and safety of drivers and passengers in the car, and achieve low production costs , The effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with specific examples. Unless otherwise specified, each component in the examples is by weight.

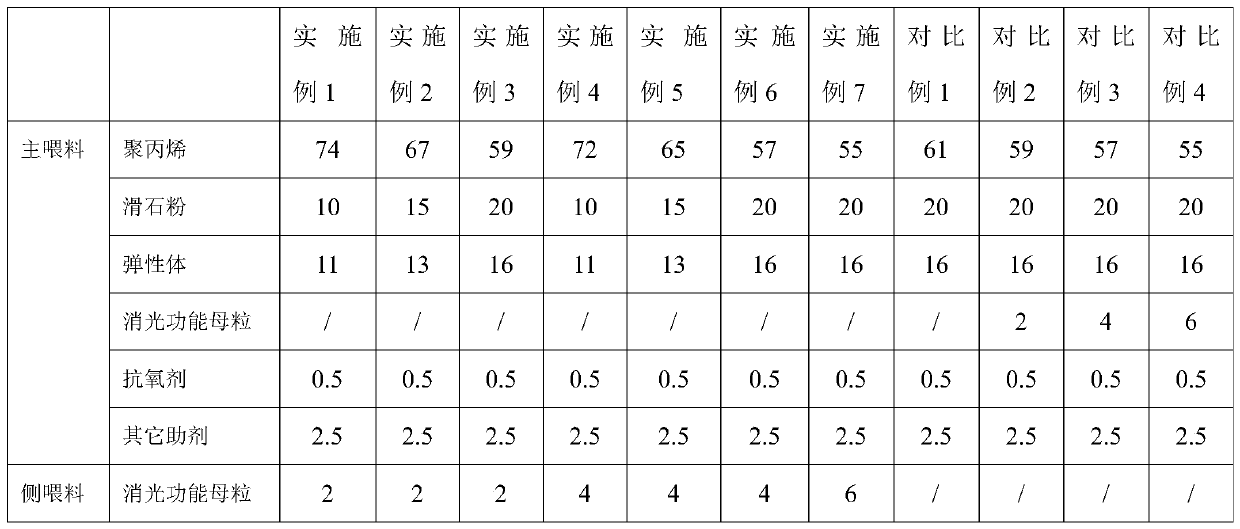

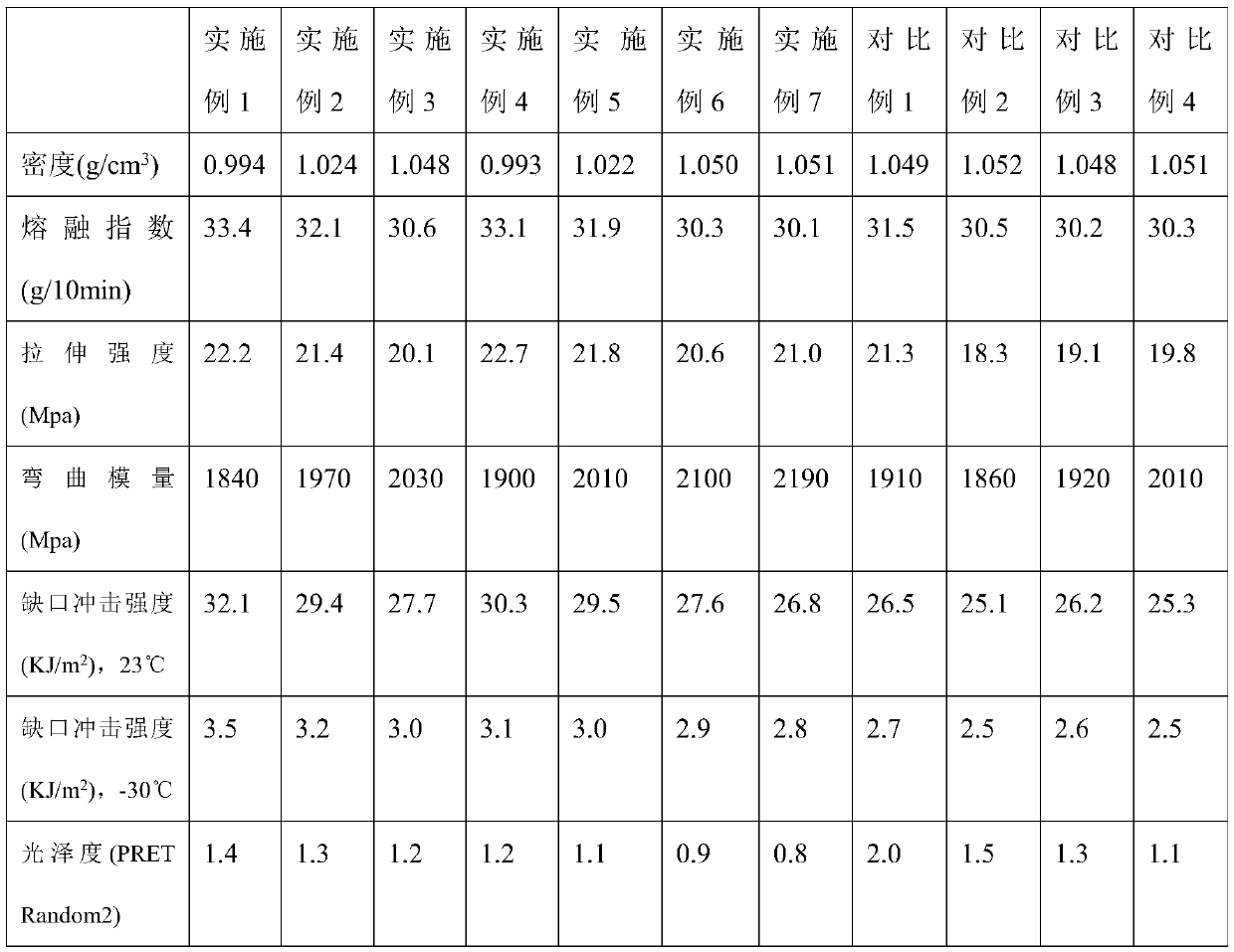

[0030] The contents of each component contained in the examples of the present invention and the comparative examples are shown in Table 1.

[0031] Table 1

[0032] Each main component content (mass percentage composition) in embodiment and comparative example

[0033]

[0034] The polypropylene described in the examples and comparative examples in Table 1 above is a copolymerized polypropylene, which is compounded with M30RH, M50RH, and BX3920 at a ratio of 1:1:1. The grades M30RH and M50RH are produced by Zhenhai Petrochemical. The melt flow The speeds are 30g / 10min and 50g / 10min respectively; the grade BX3920 is produced by SK Company in South Korea, and the melt flow rate is 100g / 10min. The talcum powder is talcum powder with a mesh number of about 2500 mesh. Described elastomer is the therm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com