a prefabricated slope

A technology for slopes and slopes, applied in the direction of sewage discharge, waterway systems, buildings, etc., can solve the problems of long construction period, complicated and complicated slope construction process, etc., to reduce the burden, make the splicing and installation process easy and convenient, and facilitate construction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

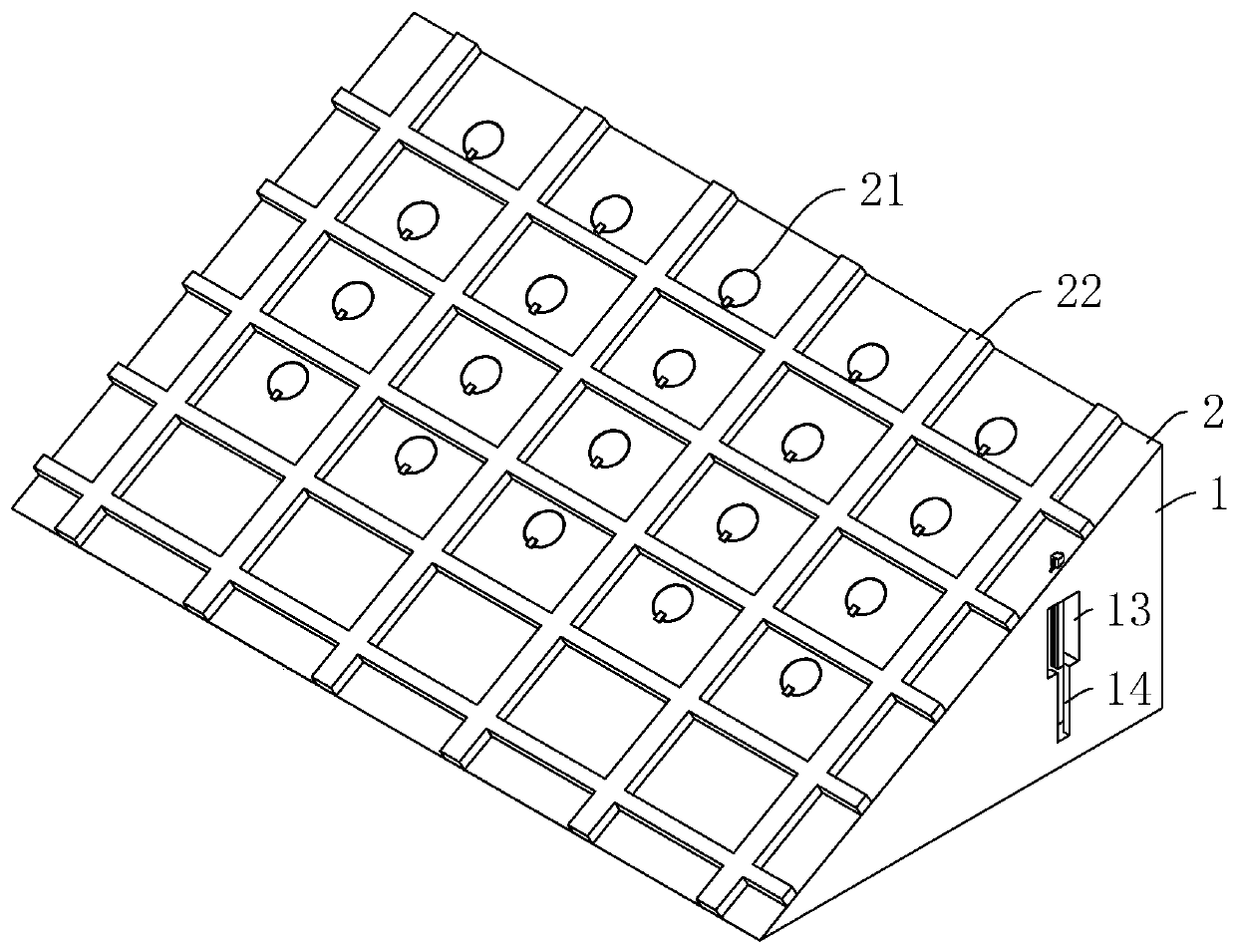

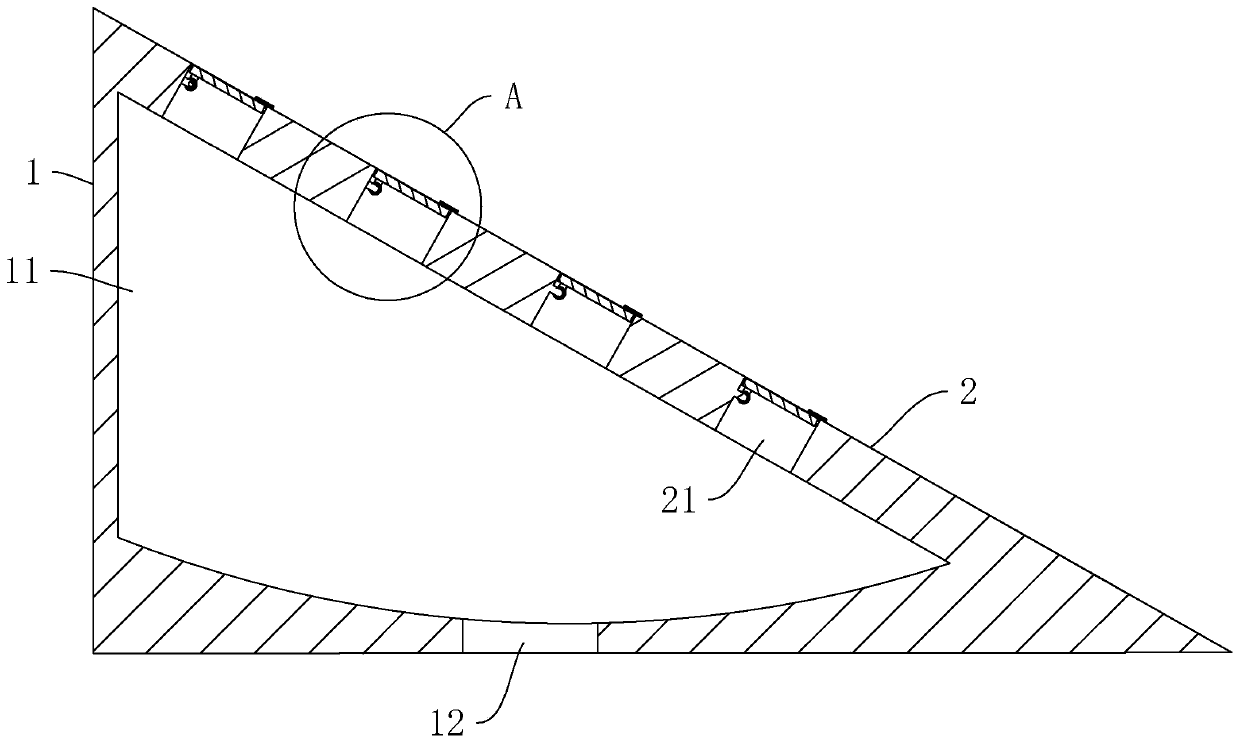

[0036] Embodiment 1: as figure 1 , figure 2 As shown, a prefabricated slope includes a slope body 1 on which a slope surface 2 is obliquely arranged. A water storage chamber 11 is arranged inside the slope body 1, and the middle part of the bottom wall of the water storage chamber 11 is lower than the surroundings, and is arranged in a circular arc transition shape. And the lower end surface of the slope body 1 is provided with a drainage hole 12 communicating with the inside of the water storage chamber 11 . A plurality of water leakage holes 21 connected to the water storage chamber 11 are evenly distributed on the slope surface 2 , and a plurality of water retaining strips 22 are intersected on the slope surface 2 .

[0037]When the above-mentioned prefabricated slopes are installed, multiple prefabricated slopes are spliced together, and the back side of the slope body 1 is fixed to the mountains on both sides of the road. When it rains, the rainwater flows along the...

Embodiment 2

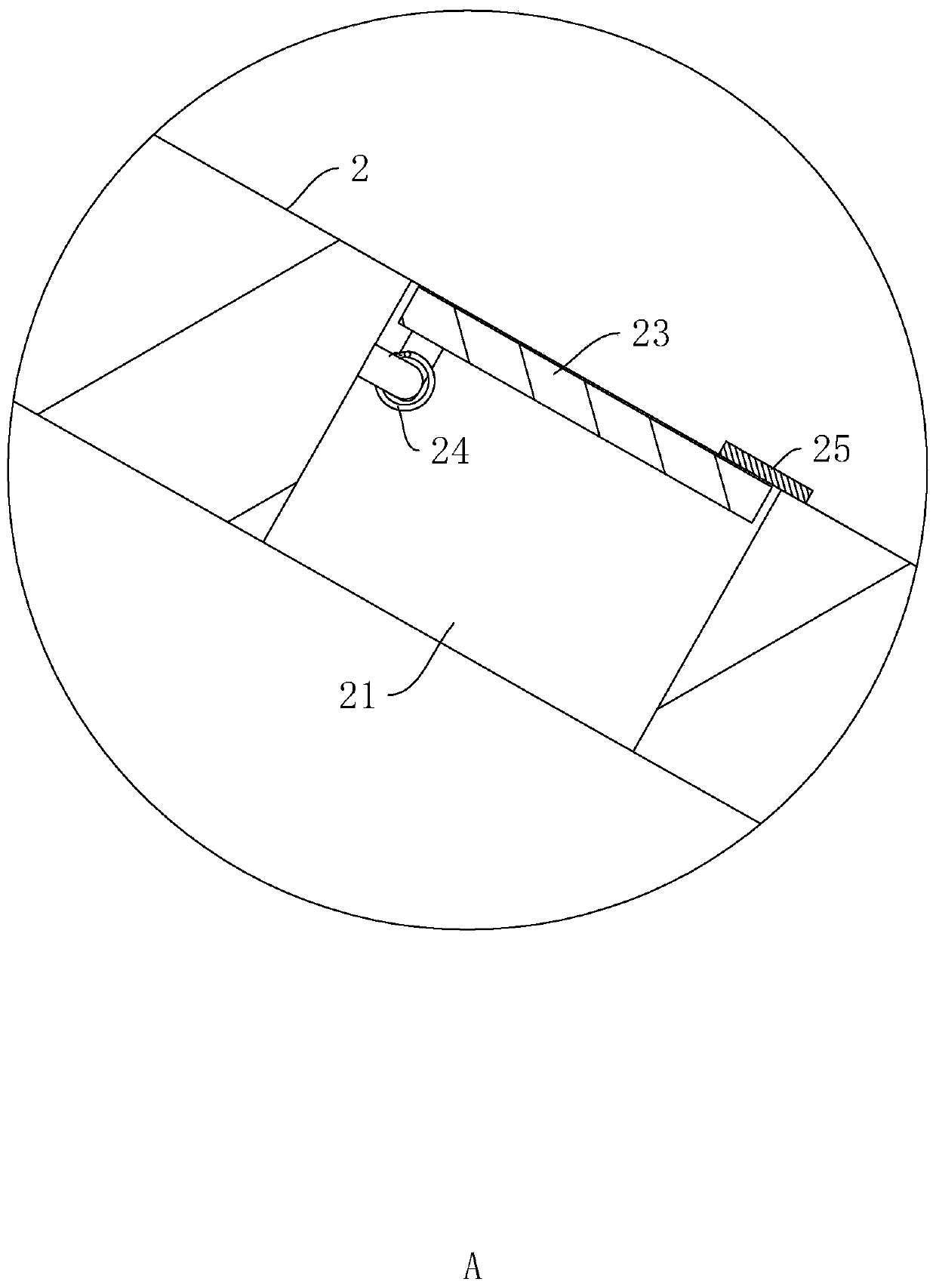

[0051] Embodiment 2: as Figure 6 As shown, the difference from Embodiment 1 is that the locking part 5 includes a locking block 52 slidably connected to the inner wall of the sliding hole 3, and the inner wall of the sliding hole 3 is provided with a sliding groove 32 for the sliding of the locking block 52, and the sliding groove 32 A return spring 33 is disposed between the bottom wall and the side wall of the locking block 52 .

[0052] Such as Figure 6 As shown, the sliding rod 4 includes a rod body 43 and an elastic block 44 disposed on the lower end surface of the rod body 43 . The side wall of the rod body 43 is also provided with a locking groove 45 for inserting the locking block 52 . Both the lower end of the elastic block 44 and the upper end of the locking block 52 are provided with arc-shaped guide surfaces 6 .

[0053] When installing the sliding rod 4 , make the side of the rod body 43 with the locking groove 45 face the locking block 52 , and then insert th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com