Manufacturing method for composite foamed cement ultra-large plate

A technology for compounding foamed cement and foamed cement board, which is applied in the direction of manufacturing tools, ceramic molding machines, etc., to achieve the effects of saving labor, small ground area, and simple, convenient and fast construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The method of the present invention will be further described below in conjunction with the accompanying drawings.

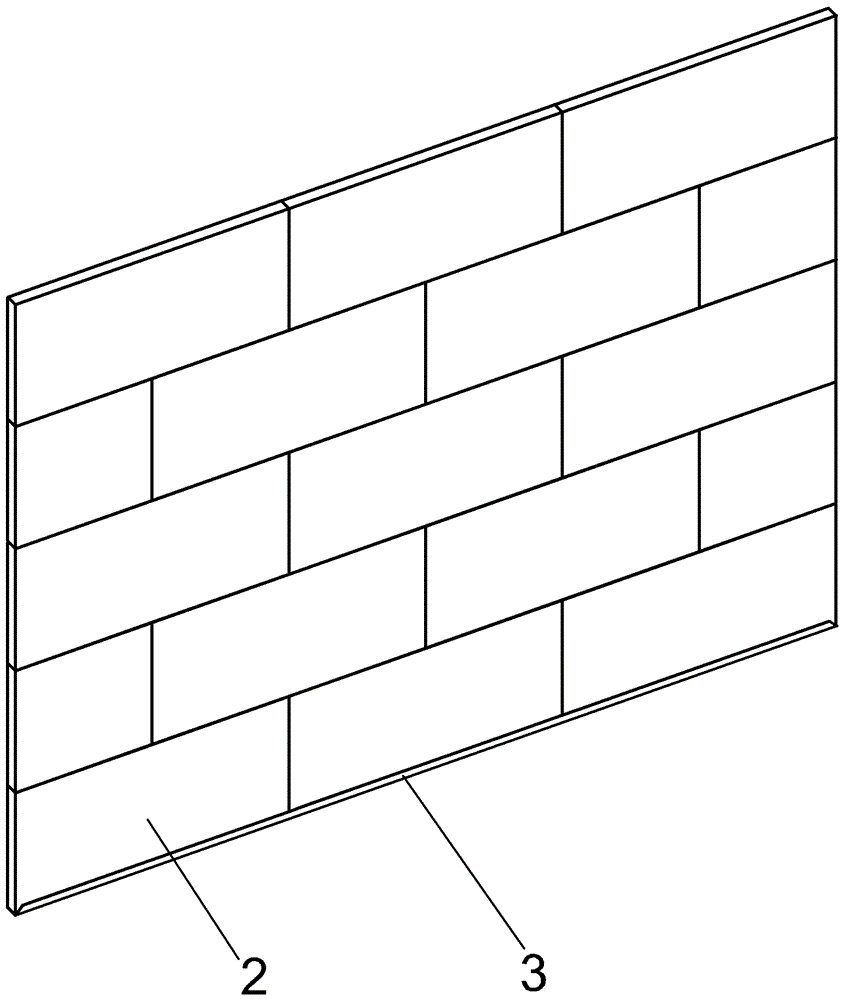

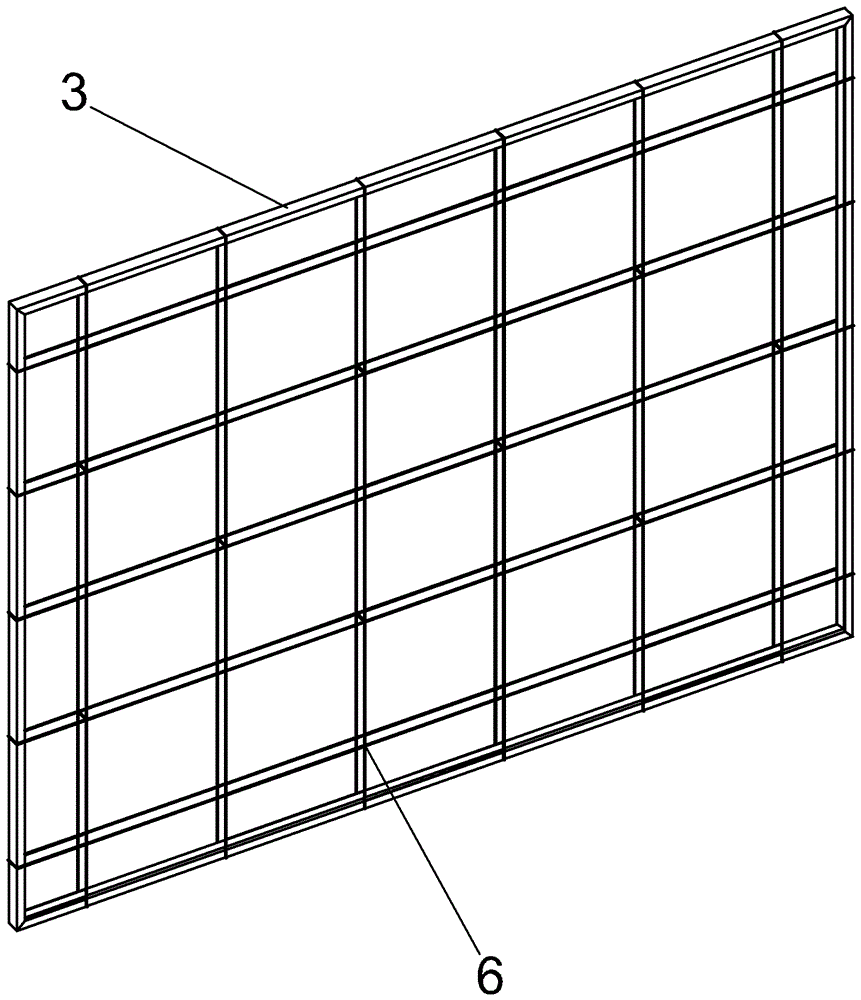

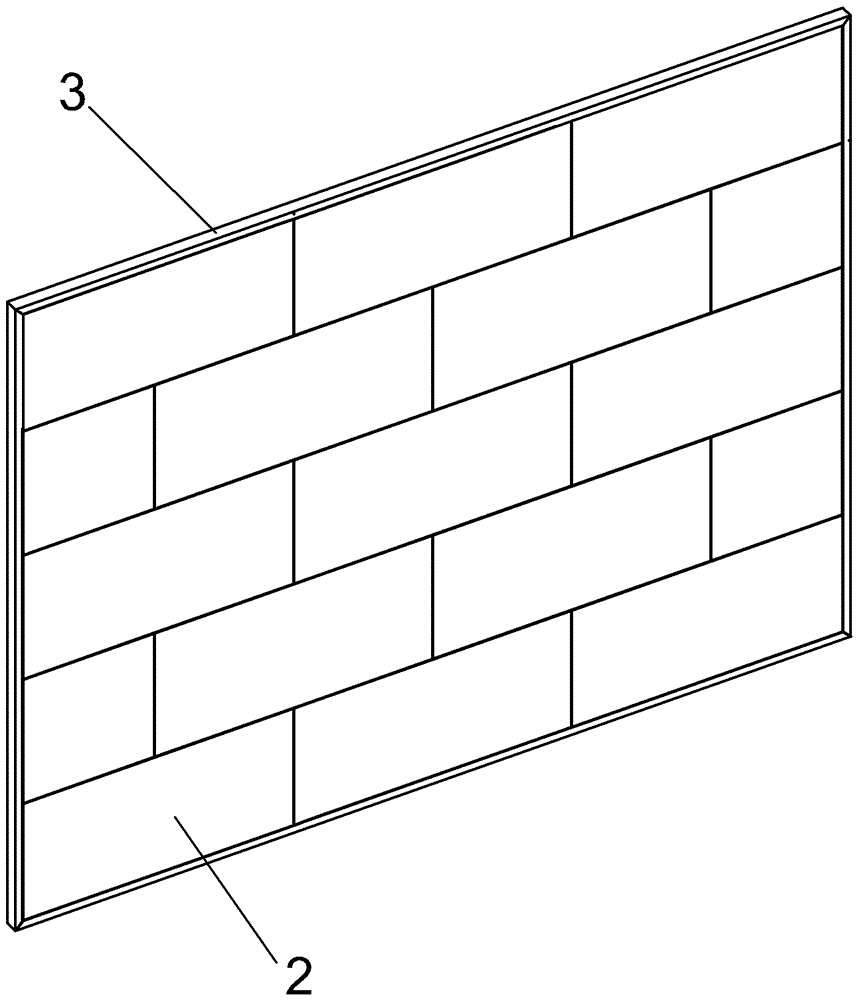

[0024] refer to figure 1 , in the manufacturing method of the composite foamed cement super-large slab of the present invention, firstly, more than 3 prefabricated foamed cement boards (2) are used to build a composite foamed cement super-large slab body of the required size, and the masonry method is a horizontal staggered type Splicing (similar to using bricks to build a wall), and the prefabricated foamed cement boards are bonded with high-strength mortar, so that the prefabricated foamed cement boards (2) can be interlaced and interlaced to bite and pull each other. The installation structure can fundamentally prevent cracking. Before laying the composite foamed cement super-large slab body, you can place the flat-shaped channel steel (3) on the ground first, put the bottom prefabricated foamed cement board in the notch of the flat-shaped channel ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com