Pressure self-adjustment crankcase ventilation valve with composite filter structure

A composite filtering and self-adjusting technology, applied in crankcase ventilation, engine components, machines/engines, etc., can solve the problems of high crankcase pressure, high crankcase pressure, complex structure, etc., and achieve automatic adjustment of crankcase pressure, high Efficient oil and gas separation, compact structure and reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

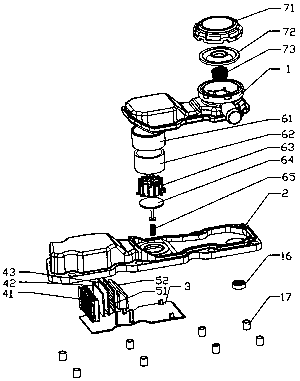

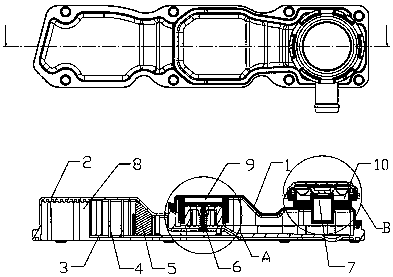

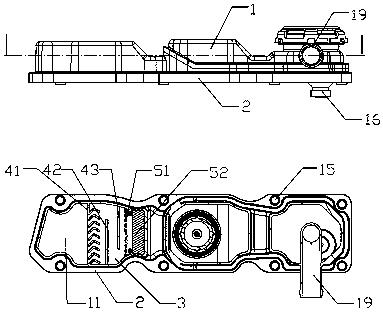

[0029] Such as Figures 1 to 7 The pressure self-adjusting crankcase breather valve of the composite filter structure of the present invention shown includes an upper cover plate 1, a middle cover plate 2, a bottom plate 3, an initial filter assembly 4, a fine filter assembly 5, and an ultrafine filter assembly 6 And the diaphragm valve assembly 7, the upper cover plate 1 and the bottom plate 3 are respectively welded to the upper and lower end faces of the middle cover plate 2, and form three cavities in sequence from left to right: the first cavity 8, the second cavity 9 and the third cavity Cavity 10, the bottom of the first cavity 8 and the second cavity 9 are connected, the primary filter assembly 4 and the fine filter assembly 5 are placed in the first cavity 8, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com