An ultra-thin heat pipe

A technology of ultra-thin heat pipe and heat insulation section, which is applied in the direction of indirect heat exchangers, lighting and heating equipment, semiconductor devices, etc., and can solve the lack of synergistic optimization of heat transfer and flow resistance, fluid flow, heat transport restrictions, and working fluid flow To solve problems such as large resistance, achieve the best cost performance, improve field synergy, and overcome the effect of large flow resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

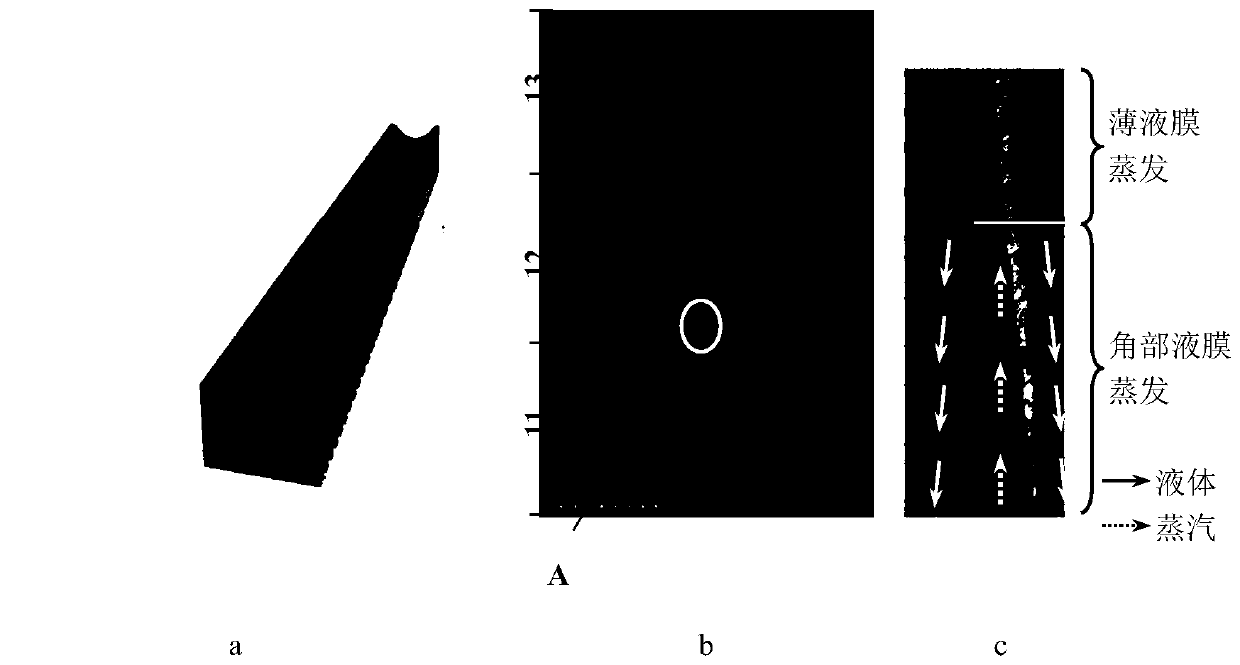

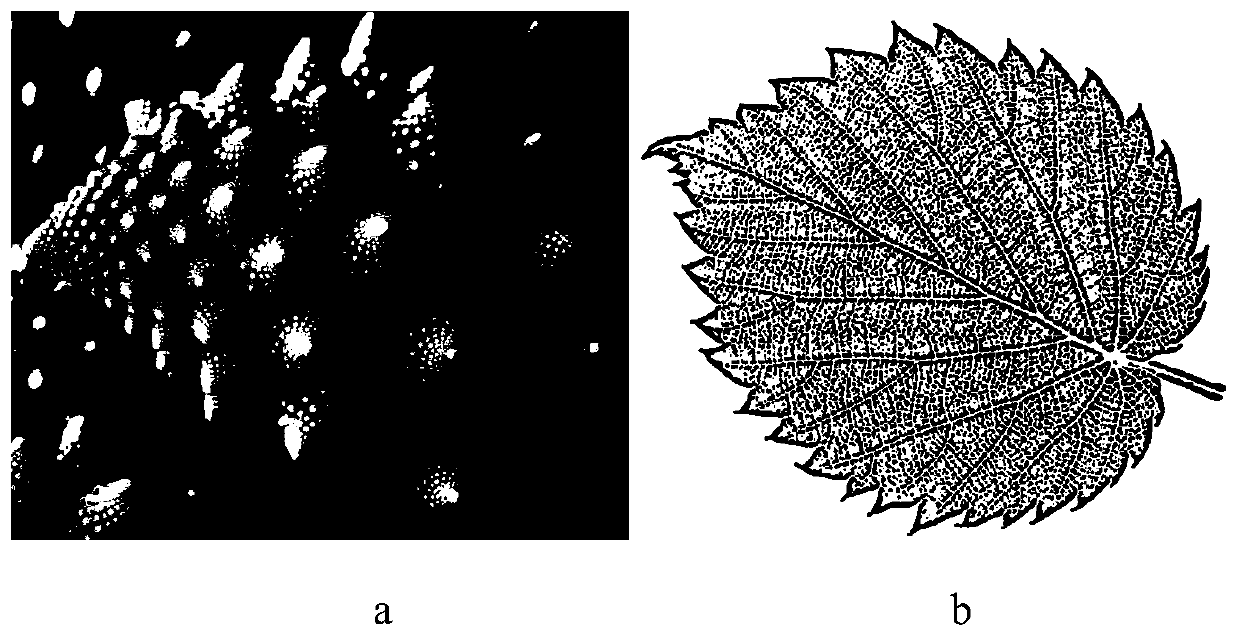

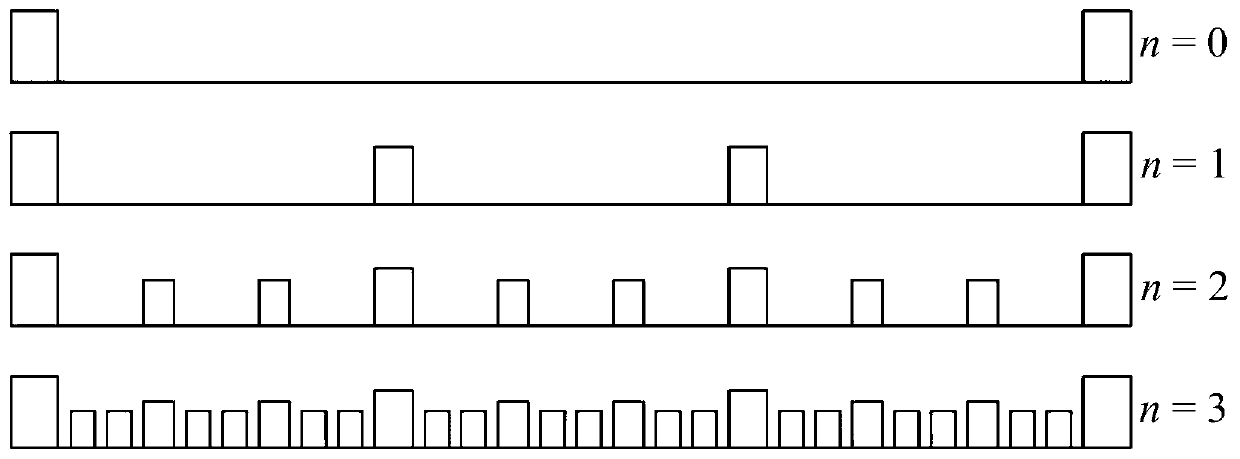

[0035] In order to solve the problems of large internal working medium flow resistance and limited maximum heat transfer capacity of existing ultra-thin heat pipes, the present invention provides a novel ultra-thin heat pipe with fractal stepped capillary core structure. The following describes the present invention in conjunction with the drawings and examples Further details. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0036] A further detailed description is carried out below in conjunction with the description of the accompanying drawings:

[0037] The invention relates to an ultra-thin heat pipe, which comprises a shell, a steam cavity and a capillary core. The inner space of the shell is a steam cavity, and the capillary core is arranged inside the shell. The ultra-thin heat pipe is provided with a condensing surface, an evaporating surface and an adiabatic sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com