Efficient anti-scale and enhanced heat exchange plate type falling film evaporation system and operation method thereof

A technology of enhanced heat transfer and falling film evaporation, applied in chemical instruments and methods, heating water/sewage treatment, water/sewage treatment, etc., can solve problems such as low evaporation efficiency, poor fluidity of evaporated mother liquor, and easy scaling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

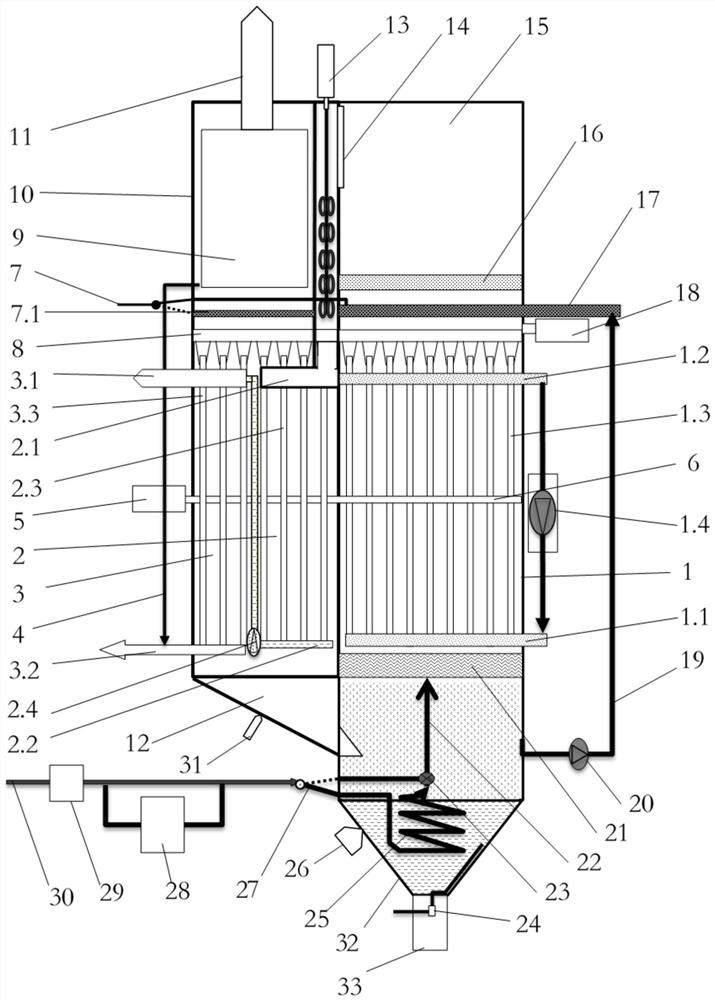

[0052] In this embodiment, according to the different management standards of the application site, the raw materials can be evaporated into materials with different water contents at one time. For example, the materials can be evaporated to a dry powder state at one time, but this operation method is uneconomical; It is more energy-saving for the material to be recycled for multiple times for evaporation and concentration. The following is a description of multiple cycle evaporation:

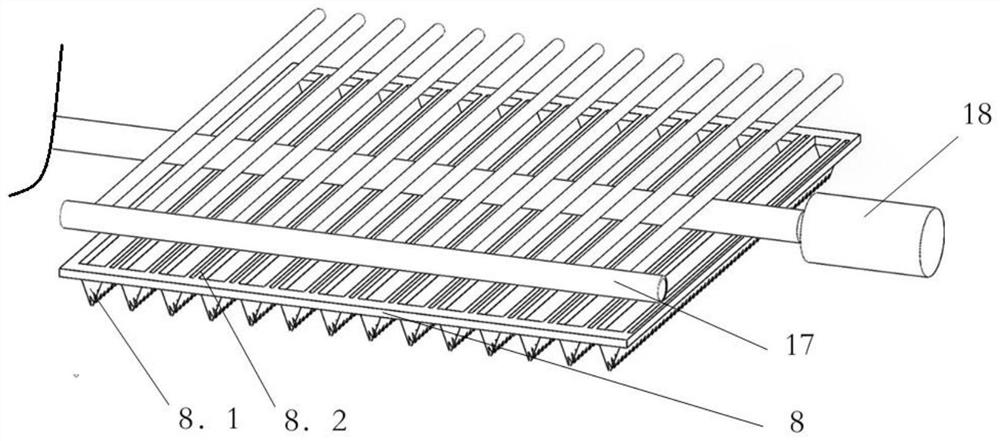

[0053] The bottom of the evaporating hopper 32 adopts a conical structure, and the bottom of the conical structure is connected to the concentrated liquid outlet 33. After the first-time heated and evaporated material is deposited in the evaporating hopper 32, the material is re-transported to the hot material circulation pump 20. Inside the material distribution shower pipe 17, the liquid film is formed on the main heat exchange plate 1.3 through the liquid distributor tank 8.1 of the liquid d...

Embodiment 2

[0055]Since the liquid film is continuously evaporated during the descending process, each main heat exchange plate 1.3 is filled with saturated steam, resulting in a decrease in the heat transfer pressure difference, thereby affecting heat transfer; The inert gas is the carrier gas, forming a vaporization core in the liquid phase body, changing the boiling mechanism, and changing the boiling heat transfer usually performed on the heated wall surface to the evaporation heat transfer process on the gas-liquid phase interface. Therefore, a carrier gas enhanced heat exchange system is provided below several groups of main heat exchange plates 1.3, and the carrier gas enhanced heat exchange system includes a carrier gas distributor 21, a carrier gas heater 25, a carrier gas three-way valve 27, a solar energy Heater 28 , air filter 29 , air inlet pipe 30 . The air inlet pipe 30 is provided with an air filter 29, the air inlet pipe 30 is connected to the carrier gas inlet pipe 22 th...

Embodiment 3

[0062] The working principle of the invention is a device for heating and evaporating the liquid film distributed on the heat exchange plates, so the uniform distribution of materials has a great influence on its production capacity and operating performance. An ideal liquid distributor can make the material form a stable and uniform liquid film on the wall of the heat exchange plate. If the liquid material is not evenly distributed, there will be bias flow or channel flow, which will cause the liquid film to be interrupted or evaporate to dryness, resulting in a dry path. This will cause fouling or scarring, which will reduce the heat transfer efficiency on the one hand and affect the service life of the evaporator on the other hand. In addition, since the carrier gas evaporating system is provided in the present invention, the carrier gas flows from bottom to top along the heat exchange plates, and reaches the evaporation chamber 15 after passing through the liquid distributo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com