Data analysis method and device and computer readable storage medium

A data analysis and data technology, applied in the field of optical fiber manufacturing, can solve the problem of incomplete analysis of complex causes of fiber breakage, and achieve the effect of saving labor costs and time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

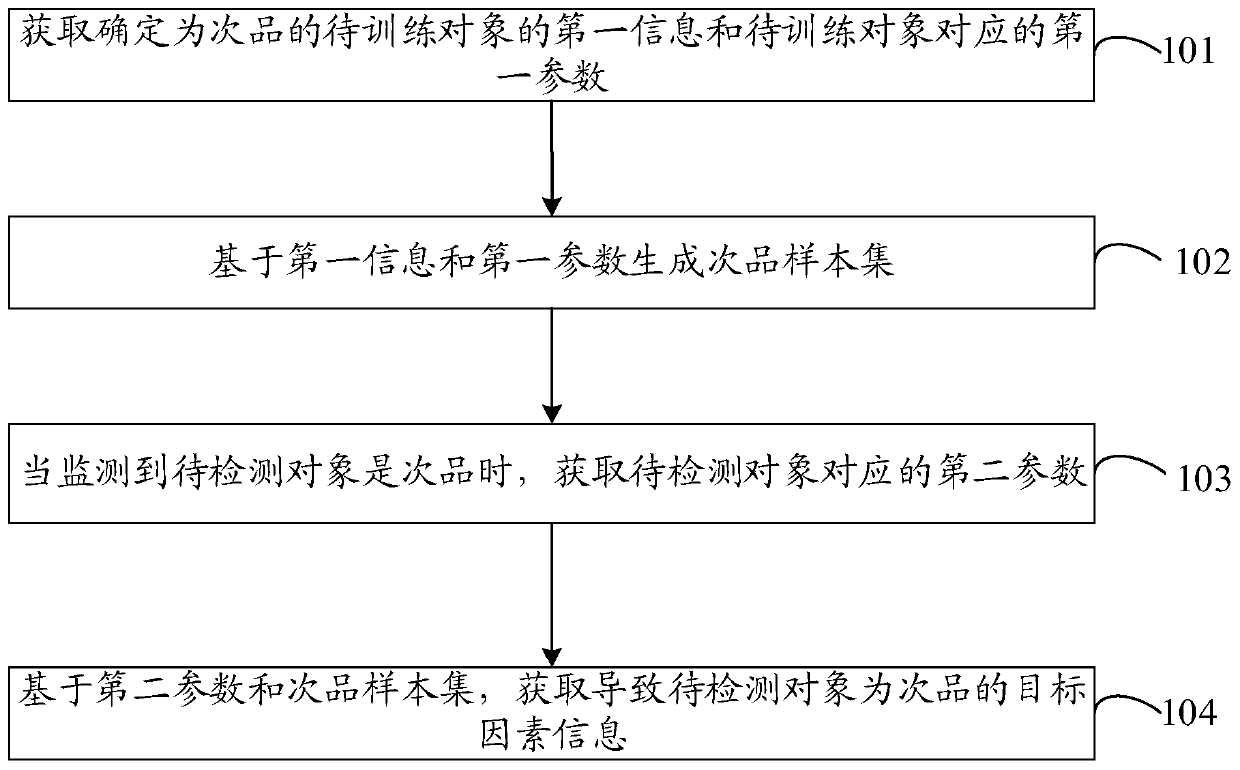

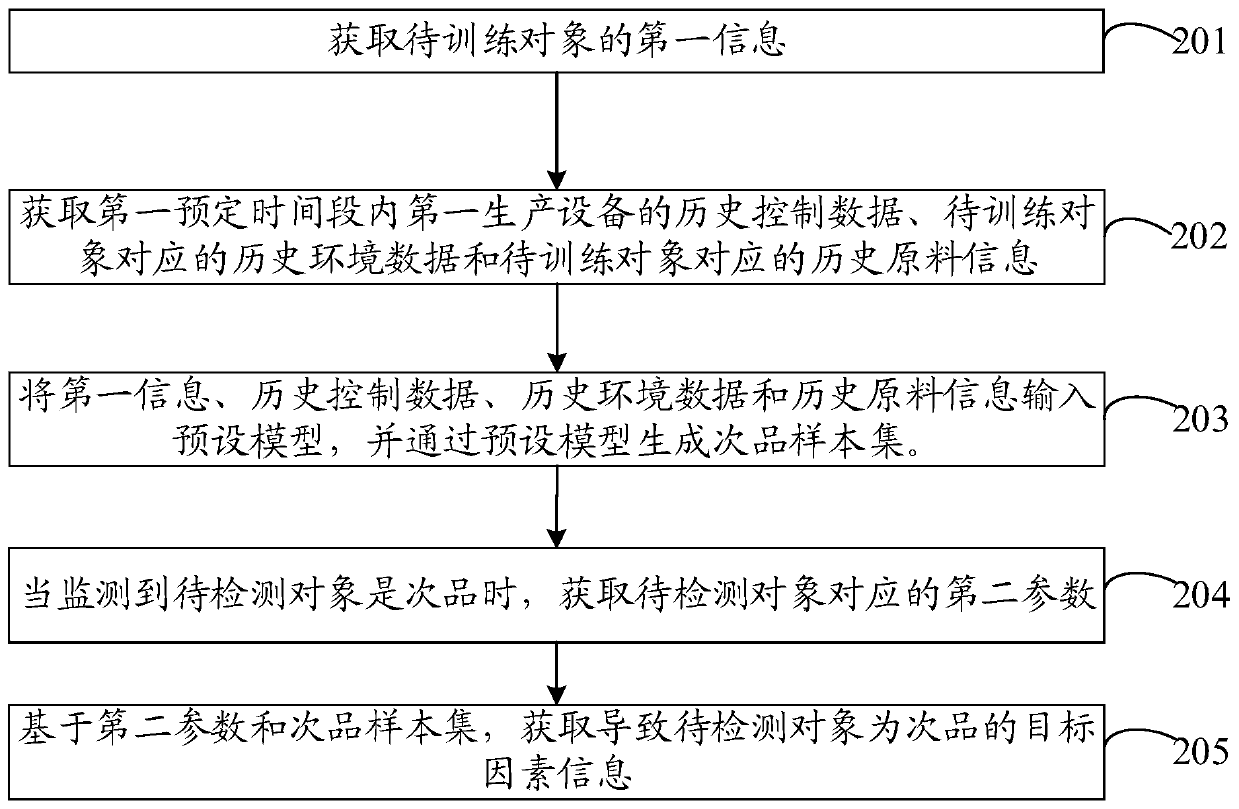

[0060] An embodiment of the present invention provides a data analysis method, the data analysis method is applied to data analysis equipment, refer to figure 1 As shown, the data analysis method of this embodiment includes the following steps:

[0061] Step 101: Obtain the first information of the object to be trained determined to be a defective product and the first parameter corresponding to the object to be trained, wherein the first information is used to represent the factor information that causes the object to be trained to be a defective product, and the first parameter is used for It represents the historical production data produced by the first production equipment producing the object to be trained within the first predetermined time period.

[0062] It can be u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com