Water turbine rotating shaft state monitoring method and system based on a neural network

A neural network and hydraulic turbine technology, applied in the neural network-based hydraulic turbine shaft state monitoring method and system field, can solve the problem of affecting the safety and stability of the power grid, unplanned outage of hydraulic turbine failures and increased sudden impact faults, unable to meet rapid fault location and timely processing of actual engineering needs and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to facilitate those skilled in the art to understand the technical content of the present invention, the content of the present invention will be further explained below in conjunction with the accompanying drawings.

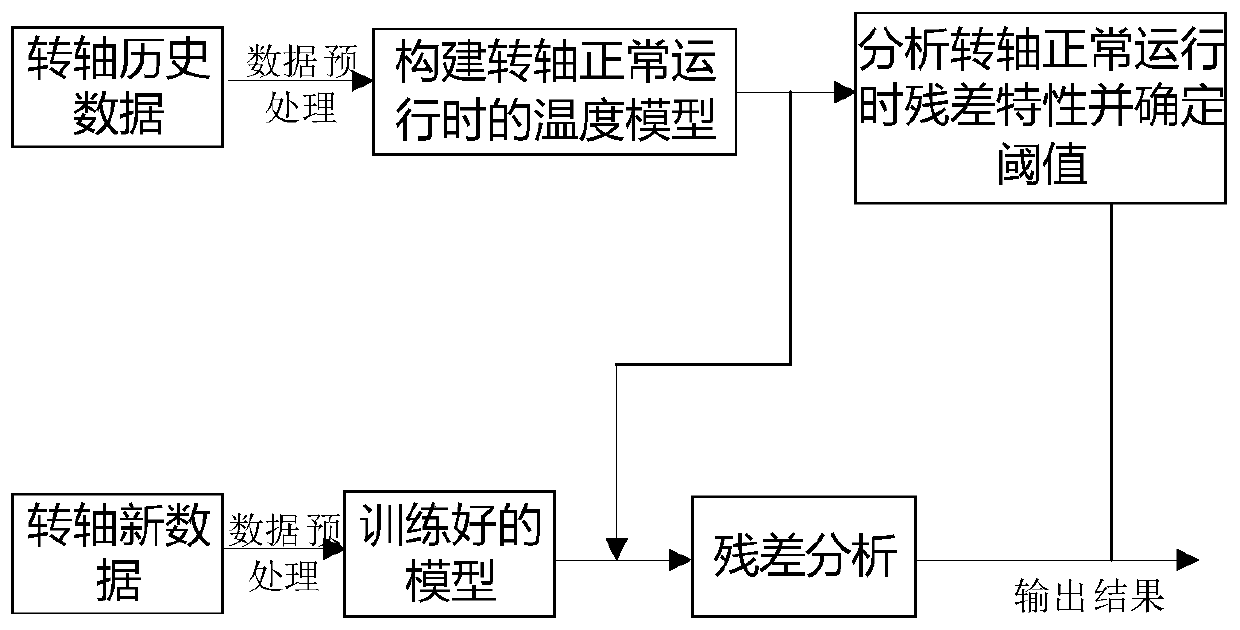

[0029] figure 1 It is a system framework diagram of the present invention. The present invention will be described in detail below according to the accompanying drawings and in combination with actual conditions. Such as figure 1 The forecasting flow chart is shown.

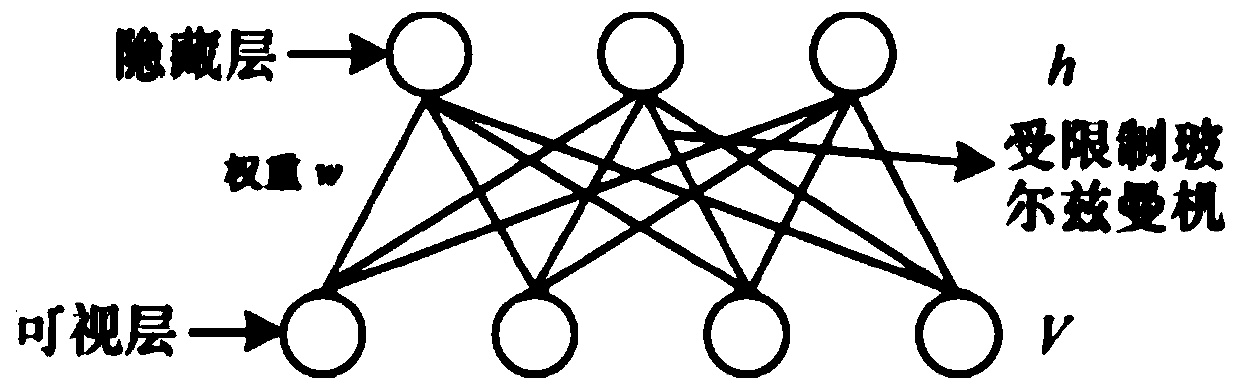

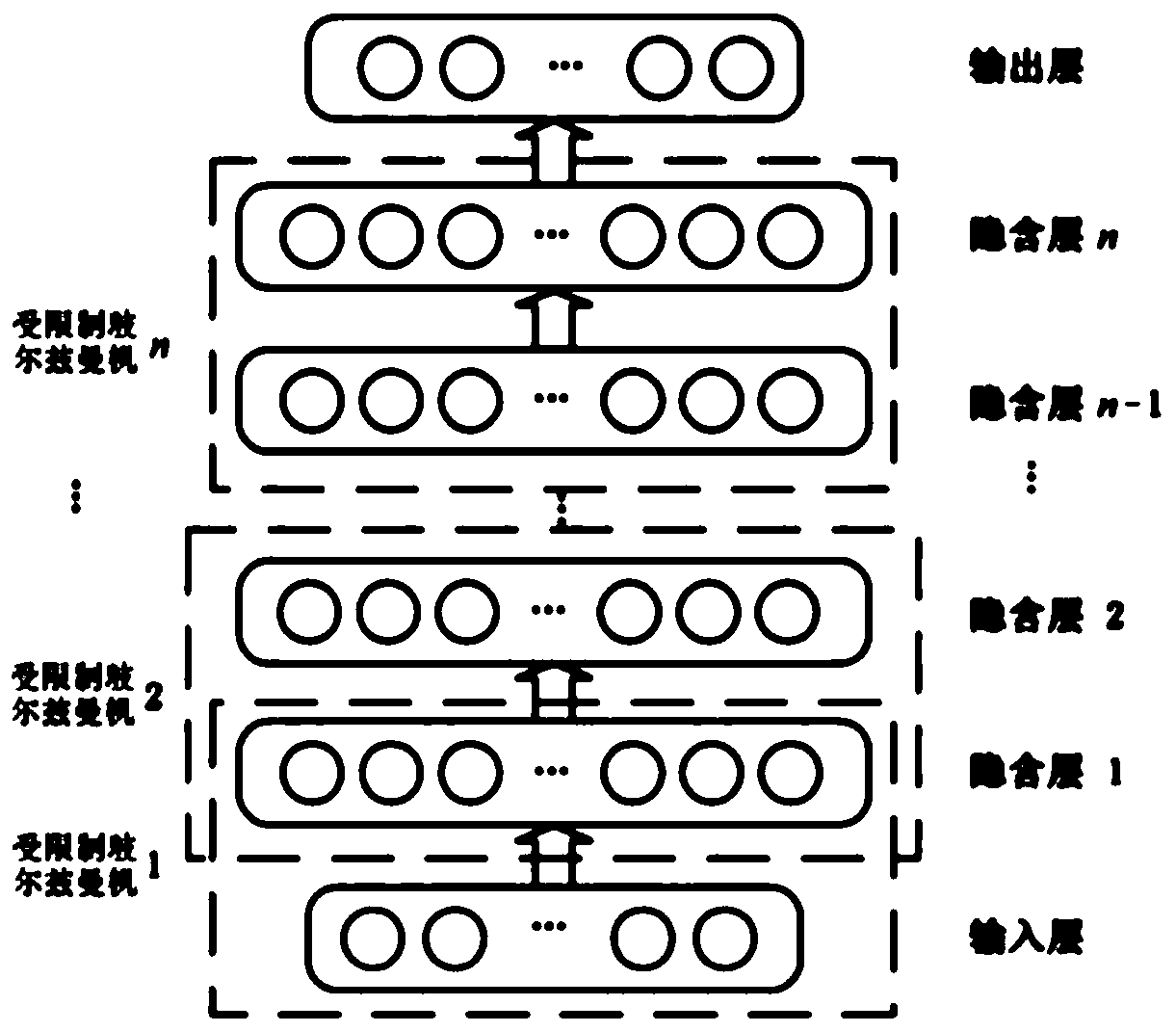

[0030] The historical data of the rotating shaft includes many continuous parameters such as the temperature, rotating speed and ambient temperature of the rotating shaft. Pre-train these data, and initialize the connection weights and bias values between the layers of the neural network in an unsupervised greedy layer-by-layer manner. After training, after the first layer is completed, the parameters of its hidden layer are used as the second layer The input to train the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com