Power line

A technology for power cords and wires, which is applied to circuits, insulated cables, power cables, etc., can solve the problems of reduced service life of core wires, easy combustion of power cords, and swaying of outlets, achieving long service life, reducing incidence, and ensuring installation The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

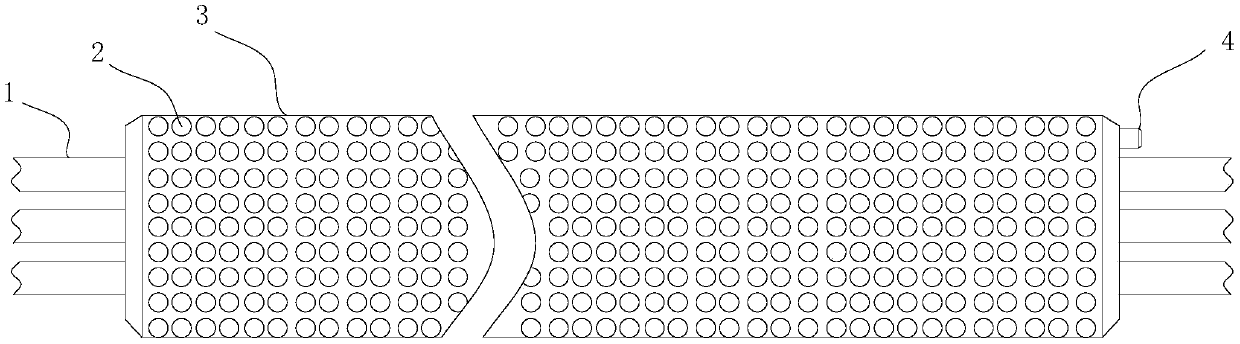

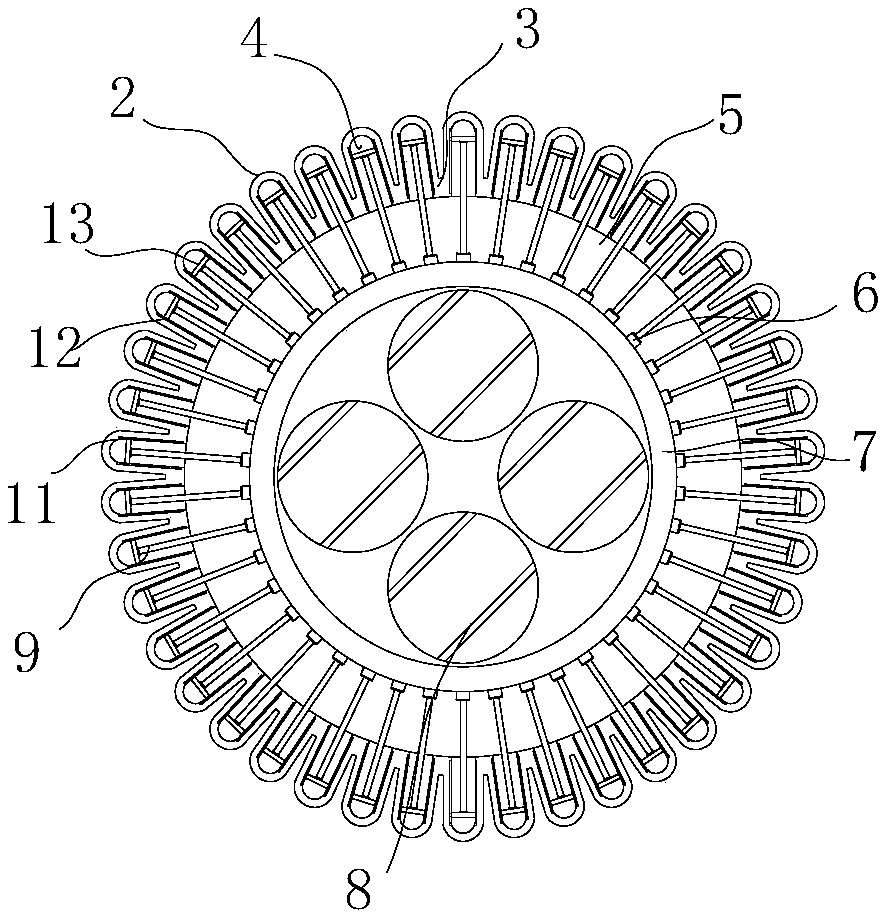

[0018] Such as figure 1 and figure 2 As shown, a power cord includes a wire outer coating layer 3, an air-filled cavity 5 is provided inside the wire outer coating layer 3, and more than one inner core wire 8 is arranged in the air-filled cavity 5, and more than one inner core wire 8 passes through The inner protective layer 7 is wrapped, and more than one positioning sleeve 2 is provided on the outer layer 3 of the wire rod, and each positioning sleeve 2 is provided with a movable cavity 4, and a guide chute is provided on both sides of the inner wall of the movable cavity 4 11. A piston 13 is installed in the movable chamber 4, and a slider 12 is arranged on both sides of the piston 13. The slider 12 is slidably installed in the guide chute 11, and the outer surfaces of more than one positioning sleeve 2 are in contact with each other. Interstitial cavities are formed between the positioning sleeves 2 .

[0019] In this embodiment, the wire rod outer layer 3 is made of el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com