Negative plate of secondary nickel-hydrogen battery and manufacturing method thereof

A technology of nickel-hydrogen battery and production method, which is applied to nickel storage battery, battery electrode, alkaline storage battery electrode and other directions, can solve the problems of expensive alloy powder and high cost of negative electrode production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

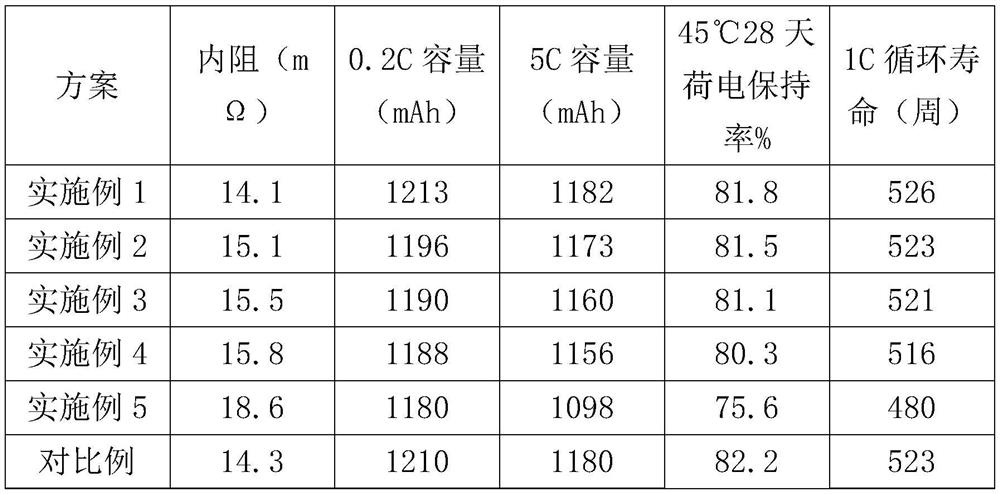

Examples

Embodiment 1

[0055] Mix and stir alloy powder, ferric oxide, nickel hydroxide, ferrous sulfide, graphite, and binder in a weight ratio of 80:18.5:0.5:0.5:0.5:32 to obtain slurry, and apply the slurry to The steel strip is rolled and cut to obtain the negative electrode sheet.

Embodiment 2

[0057] Mix alloy powder, ferric oxide, nickel hydroxide, ferrous sulfide, graphite, and binder in a weight ratio of 70:27.5:1:1:0.5:34 to obtain a slurry, and apply the slurry to The steel strip is rolled and cut to obtain the negative electrode sheet.

Embodiment 3

[0059] Mix and stir alloy powder, ferric oxide, nickel hydroxide, ferrous sulfide, graphite, and binder at a weight ratio of 60:37:1:1.5:0.5:34 to obtain a slurry, and apply the slurry to The steel strip is rolled and cut to obtain the negative electrode sheet.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com