A green belt pruning system and its pruning method based on laser cutting

A laser cutting and green belt technology, which is applied in laser welding equipment, hedge trimming equipment, metal processing equipment, etc., can solve the problems of unsuitable trimming of green belts, dust pollution, long time consumption, etc., to prevent pest virus invasion, The effect of reducing noise pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

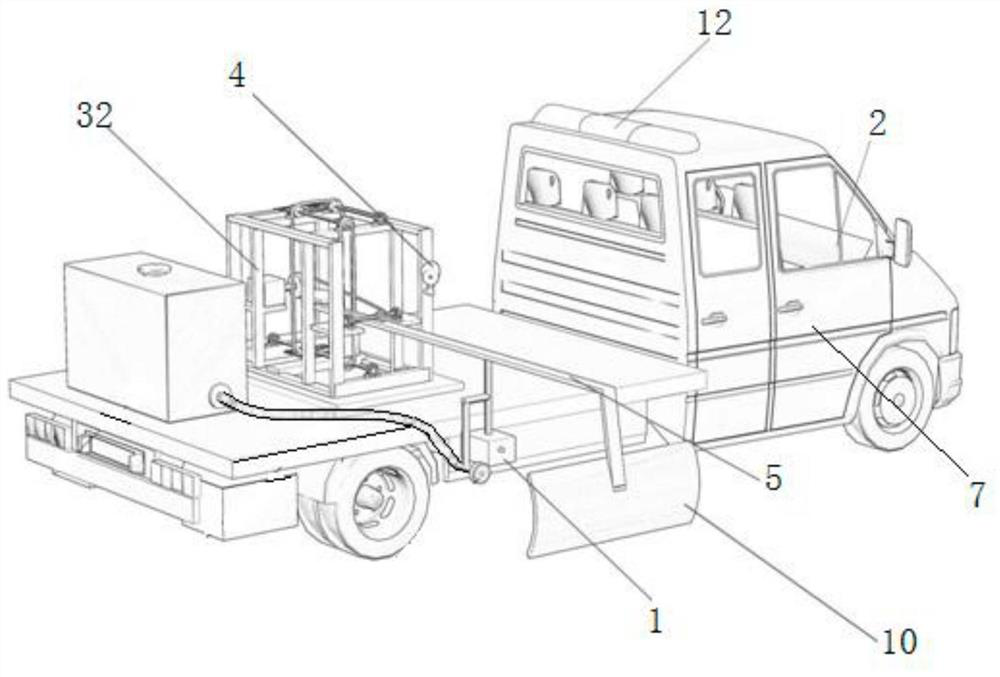

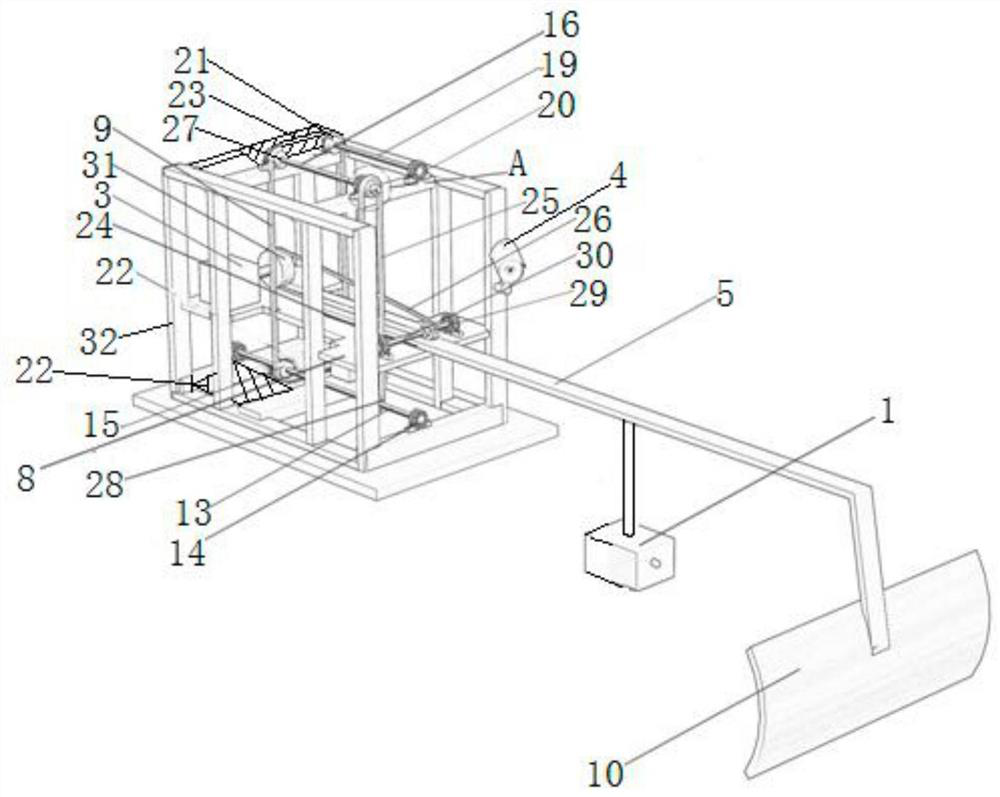

[0040] A green belt pruning system based on laser cutting of the present invention, such as Figure 1~3 Shown, comprise pruning car 7, be provided with elevating device on pruning car 7, elevating device comprises frame 32, and the bottom of frame 32 is provided with support tube I13, and the two ends of support tube I13 pass bearing block I14 and frame 32 respectively. connection, the support tube I13 is also coaxially sleeved with a synchronous wheel I15 and a synchronous wheel V28;

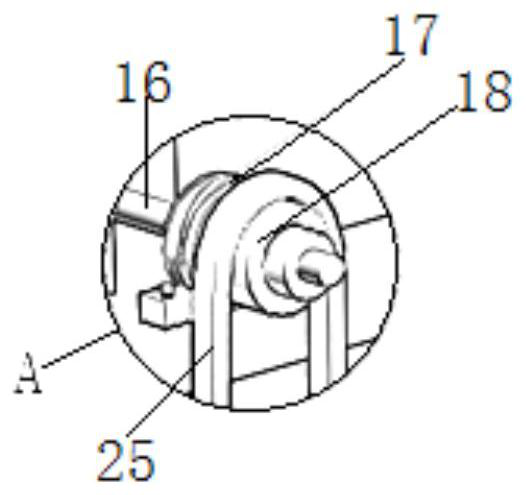

[0041] The top of the frame 32 is respectively provided with mutually parallel support tube II16 and support tube III19, both of the support tube II16 and the support tube III19 are parallel to the support tube I13, and the two ends of the support tube II16 are coaxially socketed with synchronous wheel II18 and synchronous wheel II18 respectively. wheel IV27,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com