Rare earth impact resistance steel plate and preparation method thereof

An impact-resistant steel plate technology, applied in the field of impact-resistant steel, can solve the problems of poor plate shape and processing performance, high price, etc., and achieve the effects of improving impact resistance, increasing strength and toughness, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

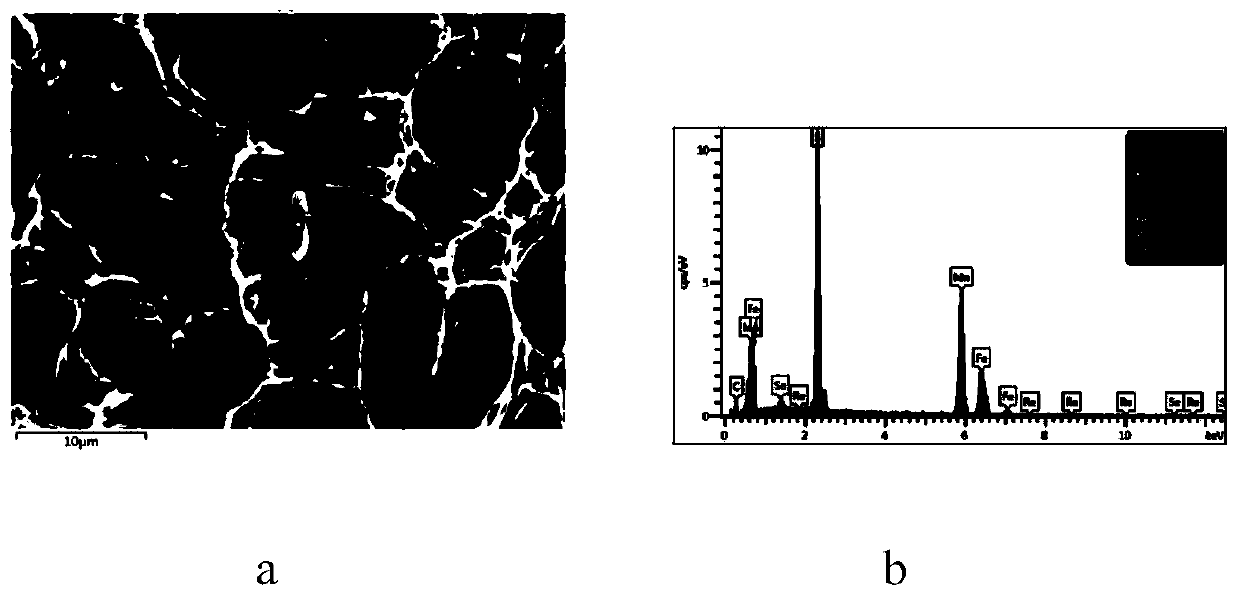

[0030] A rare earth impact steel sheet, according to C 0.35%; Si 0.3%; Mn 0.9%; Cr 1%; Ni 2%; Mo0.3%; V 0.18%; Nb 0.02%; P 0.006%; S 0.005%; 0.006%; the rest are the inevitable impurity components of Fe element for batching, and the following preparation process is completed:

[0031] (1) Smelting: The vacuum induction furnace is used to smelt the steel ingot. The specific processes include: charging, melting, refining, alloying and deoxidation, and pouring;

[0032] (2) Forging: The smelted steel ingot is heated to 1250°C for 8 hours for hammer forging. The forging adopts a 700Kg air hammer, the initial forging temperature is 1150°C, and the final forging temperature is 950°C; the size of the formed billet is: 140mm×140mm×200mm;

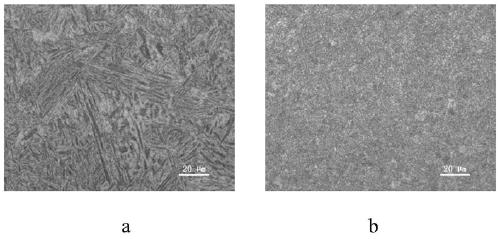

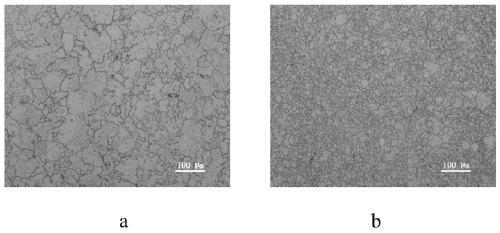

[0033] (3) Rolling: The 140mm×140mm×200mm billet is heated to 1280°C, kept for 1 hour, and rolled after being released from the furnace. The rolling is divided into 4 passes, and the 140mm thick billet is rolled into a 30mm thick steel plate. Cooli...

Embodiment 2

[0039] A rare earth impact steel sheet, according to C 0.35%; Si 0.3%; Mn 0.9%; Cr 1%; Ni 2%; Mo0.3%; V 0.18%; Nb 0.02%; P 0.006%; S 0.005%; 0.0075%; the rest are the inevitable impurity components of Fe element for batching, and the following preparation process is completed:

[0040] (1) Smelting: The vacuum induction furnace is used to smelt the steel ingot. The specific processes include: charging, melting, refining, alloying and deoxidation, and pouring;

[0041] (2) Forging: The smelted steel ingot is heated to 1270°C for 8 hours for hammer forging. The forging adopts a 700Kg air hammer, the initial forging temperature is 1160°C, and the final forging temperature is 955°C; the size of the formed billet is: 140mm×140mm×200mm;

[0042] (3) Rolling: The 140mm×140mm×200mm billet is heated to 1290°C, kept for 1 hour, and rolled after being released from the furnace. The rolling is divided into 4 passes, and the 140mm thick billet is rolled into a 30mm thick steel plate. Cool...

Embodiment 3

[0045] A rare earth impact steel sheet, according to C 0.35%; Si 0.3%; Mn 0.9%; Cr 1%; Ni 2%; Mo0.3%; V 0.18%; Nb 0.02%; P 0.006%; S 0.005%; 0.009%; the rest are the inevitable impurity components of Fe element for batching, and the following preparation process is completed:

[0046] (1) Smelting: The vacuum induction furnace is used to smelt the steel ingot. The specific processes include: charging, melting, refining, alloying and deoxidation, and pouring;

[0047] (2) Forging: The smelted steel ingot is heated to 1270°C for 8 hours for hammer forging. The forging adopts a 700Kg air hammer, the initial forging temperature is 1170°C, and the final forging temperature is 960°C; the size of the formed billet is: 140mm×140mm×200mm;

[0048] (3) Rolling: The 140mm×140mm×200mm billet is heated to 1300°C, kept for 1 hour, and rolled after being released from the furnace. The rolling is divided into 4 passes, and the 140mm thick billet is rolled into a 30mm thick steel plate. Cooli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com