Environment-friendly indirect type roller heating device with heat preservation

A heating device and an environmentally friendly technology, which is applied in the field of built-in indirect drum heating device with thermal insulation and environmental protection, can solve the problems of uneven heating of asphalt mixture, damage to the gradation of asphalt mixture, easy-to-burn asphalt material, etc., to achieve temperature rise Controllable, low heating cost, uniform temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

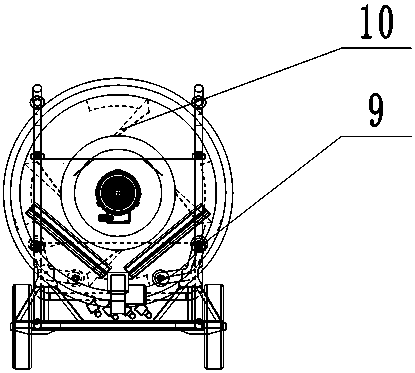

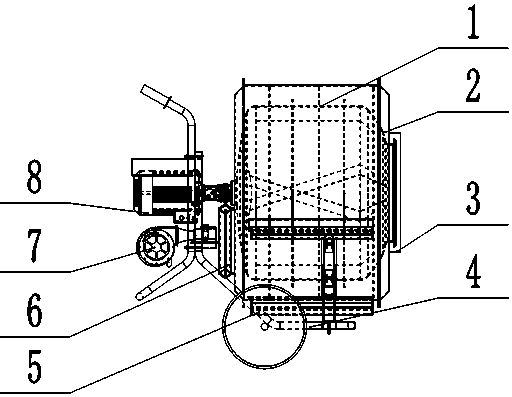

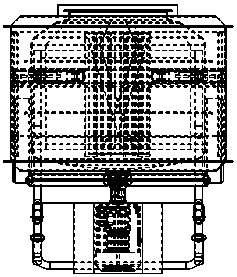

[0022] An environment-friendly indirect drum heating device with heat preservation, comprising a heat preservation cover 2 and a drum 1 arranged in the heat preservation cover 2, the outer wall of the drum 1 is provided with a supporting wheel 9 for supporting and rotating the rotation of the drum 1;

[0023] Wire heaters 5 are arranged on the outer wall of the drum 1, and the wire heaters 5 are distributed on the drum 1 at multiple points;

[0024] The inside of the drum 1 is provided with guide vanes 10 for stirring materials.

[0025] A pressurized blower 6 is arranged on the outer wall of the heat preservation cover 2, and a heater 7 corresponding to the pressurized blower 6 is provided;

[0026] The hot air formed by the heating of the heater 7 is blown into the heat preservation cover 2 through the pressurized fan 6 to heat the drum 1 .

[0027] The heat preservation cover 2 is provided with an openable cover 3 .

[0028] The guide vane 10 is arranged in a left-right a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com