A production-based automatic dredging control method for cutter suction dredgers

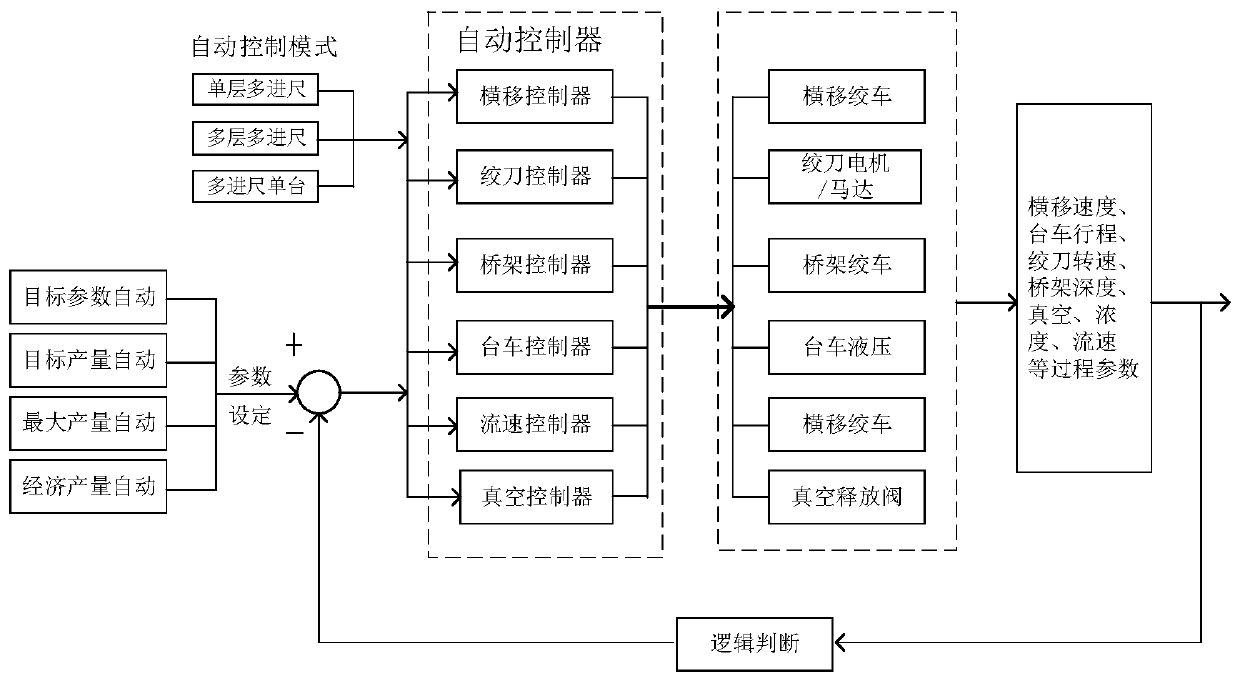

A cutter suction dredger and control method technology, which is applied in the direction of earth mover/shovel, mechanically driven excavator/dredger, construction, etc., can solve the problem that the construction output of dredger is not high, and the safety of equipment is not high , high labor intensity and other issues, to achieve the effect of realizing automated construction operations, improving dredging efficiency, and improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

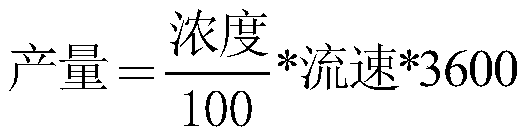

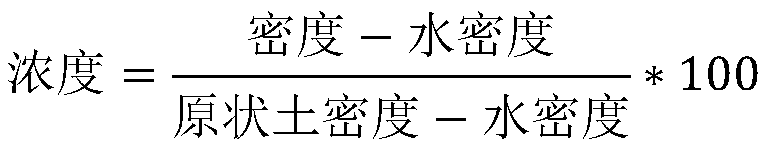

[0061] In the example, set the excavation mode of multi-footage and multi-layer single truck, select the target parameter under automatic dredging control, set the traverse speed to 13m / min, each step of the trolley is 1.5m, and the depth of each layer is 1.5m. Other setting parameters related to traverse speed control are shown in Table 1. Using this method, the recorded working data is shown in Table 2 below:

[0062] Table 1. Main parameter setting values for traverse speed control

[0063]

[0064]

[0065] Table 2 Construction data record of an example of application of automatic control of target parameters

[0066]

[0067] Note: Process 1 is mining the first layer, process 2 is mining the second layer, and process 3 is mining the third layer.

[0068] It can be seen from Table 1 that the traverse speed is accurately controlled at the set value.

[0069] In this construction example, the sideline deceleration and other functions are verified, and the contro...

Embodiment 2

[0073] Set the excavation mode of single-layer multi-footage single truck, select the automatic dredging control function of the target output, and set the automatic control parameters as shown in Table 4 below:

[0074] Table 4 Target output automatic control parameter configuration table

[0075]

[0076]

[0077] In Example 2, according to the setting parameters in Table 4, the control function was verified, mainly verifying the response of the control system at each stage. The control function verification table is shown in Table 5 below:

[0078] Table 5 Target output automatic control function verification table

[0079] serial number function item Function Confirmation 1 The bridge frame is automatically lowered to the excavation depth OK 2 Traversing to the left line deceleration function is normal OK 3 After the footage is completed, the traverse reverse right function is normal OK 4 Traversing to the right line decele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com