Double-pipe heat exchanger used for small molten-salt heat-storage system

A heat storage system and heat exchanger technology, which is applied in the direction of heat exchanger types, indirect heat exchangers, heat storage equipment, etc., can solve the problems of unfavorable molten salt exhaustion, easy accumulation of molten salt, slow flow rate of molten salt, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

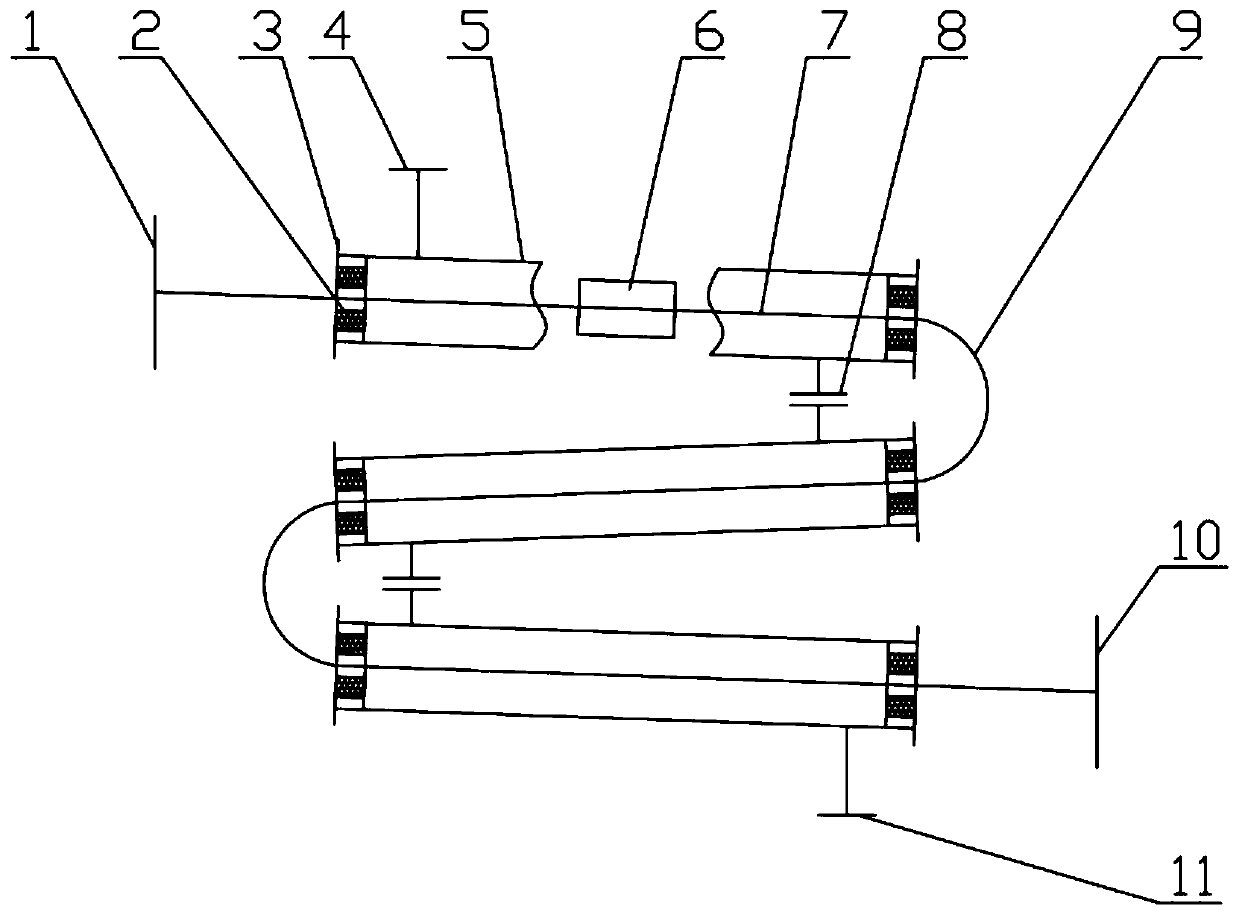

[0033] Each heat exchange unit constitutes a heat exchange process, which is composed of heat exchanger inner tube 7, heat exchanger outer tube 5, head flange and flange cover 8, sealing packing 2, support plate 6, and support plate 6 is welded on The middle section of the inner tube 7 of the heat exchanger, the head flange and the flange cover 8 are connected by bolts. The molten salt and water exchange heat through the outer wall of the inner tube 7 of the heat exchanger, and the inner tube 7 of the heat exchanger is made of seamless steel pipe. Therefore, leakage is less likely to occur.

[0034] Both the inner tube 7 of the heat exchanger and the outer tube 5 of the heat exchanger are made of seamless steel pipes, and the two ends of the outer tube 5 of the heat exchanger are fixed on the outer surface of the inner tube 7 of the heat exchanger through a flange fastener structure, and sealing packing is arranged. 2 Play a sealing role to prevent molten salt from leaking. I...

Embodiment 2

[0039] Each heat exchange unit has the same structure, so the flow rate of the heat exchanger can be superimposed according to the power requirement, and the inner pipe elbow 9 and the heat exchange unit can be directly stacked on the pipe section.

[0040] During the actual operation of the device, the molten salt is connected by the inner pipe inlet flange 7 and the inner pipe outlet flange 10 below the heat exchanger, turns back and flows in the device, and finally is discharged from the outlet of the inner pipe 7 of the heat exchanger above the heat exchanger; The water enters and exits from the lower flange 11 of the outer tube or the upper flange 4 of the outer tube respectively, turns back and flows in the gap between the inner tube 7 of the heat exchanger and the outer tube 5 of the heat exchanger, and passes through the inner tube of the heat exchanger. 7. The actual flow direction of the tube wall for heat exchange can be selected according to actual needs.

[0041] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com