Machine vision-based carrot surface defect identification and quantification method

A quantification method and defect identification technology, which is applied in the field of carrot surface defect identification and quantification based on machine vision, can solve the problems of distorted carrot purchase and sales levels, fuzzy measurement standards, and difficulty in carrot defect detection, so as to save labor costs and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The present invention will be described in further detail below in conjunction with the accompanying drawings.

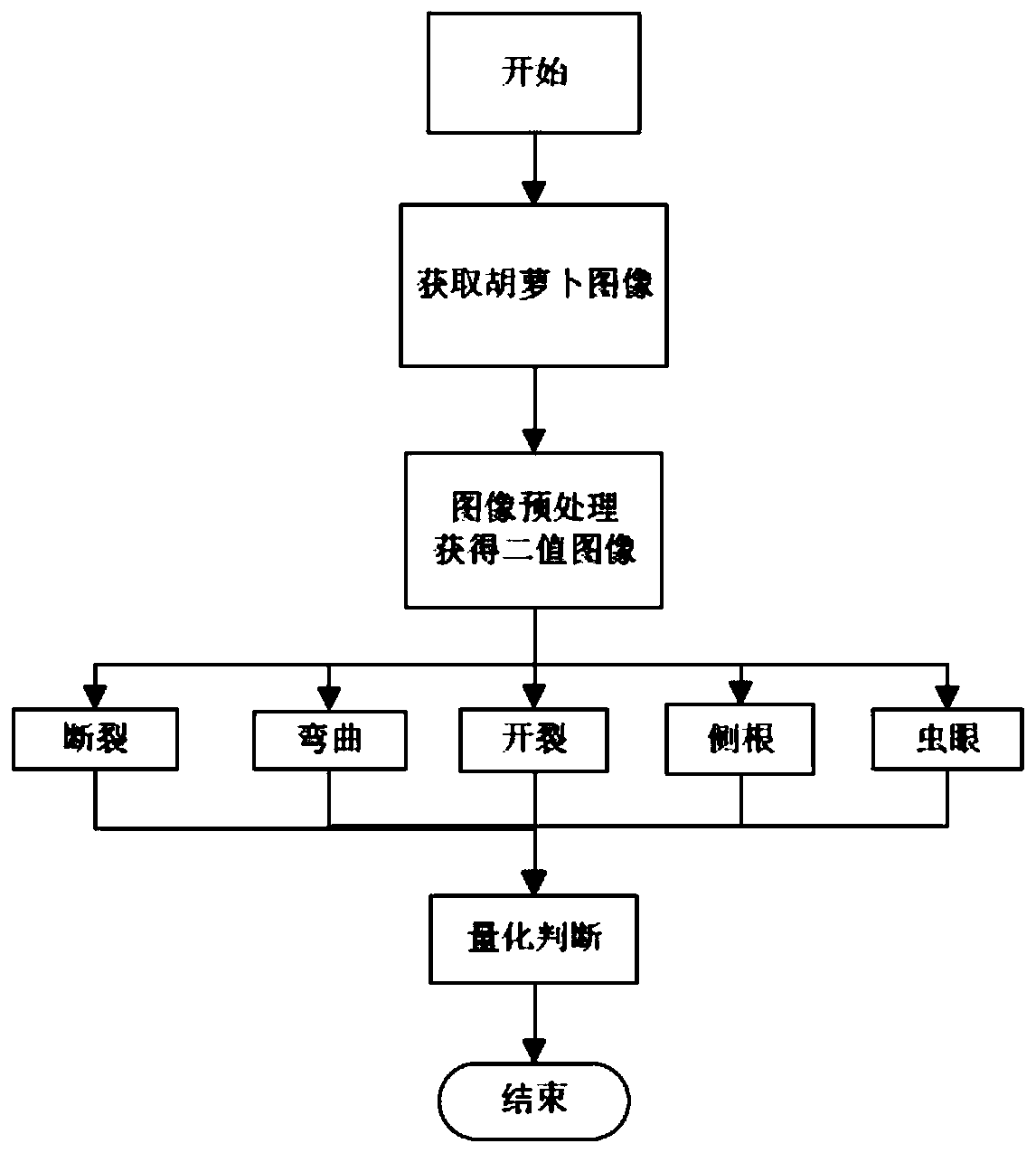

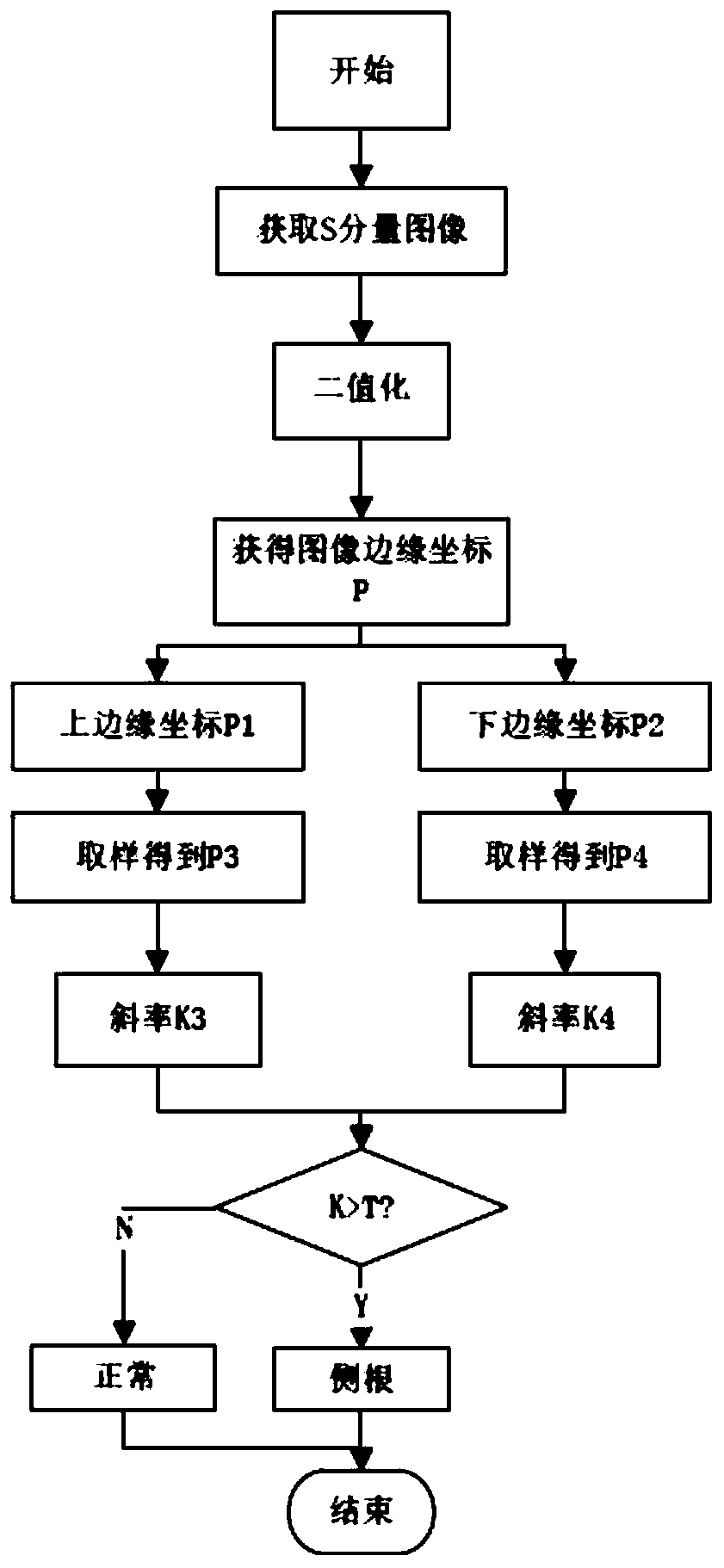

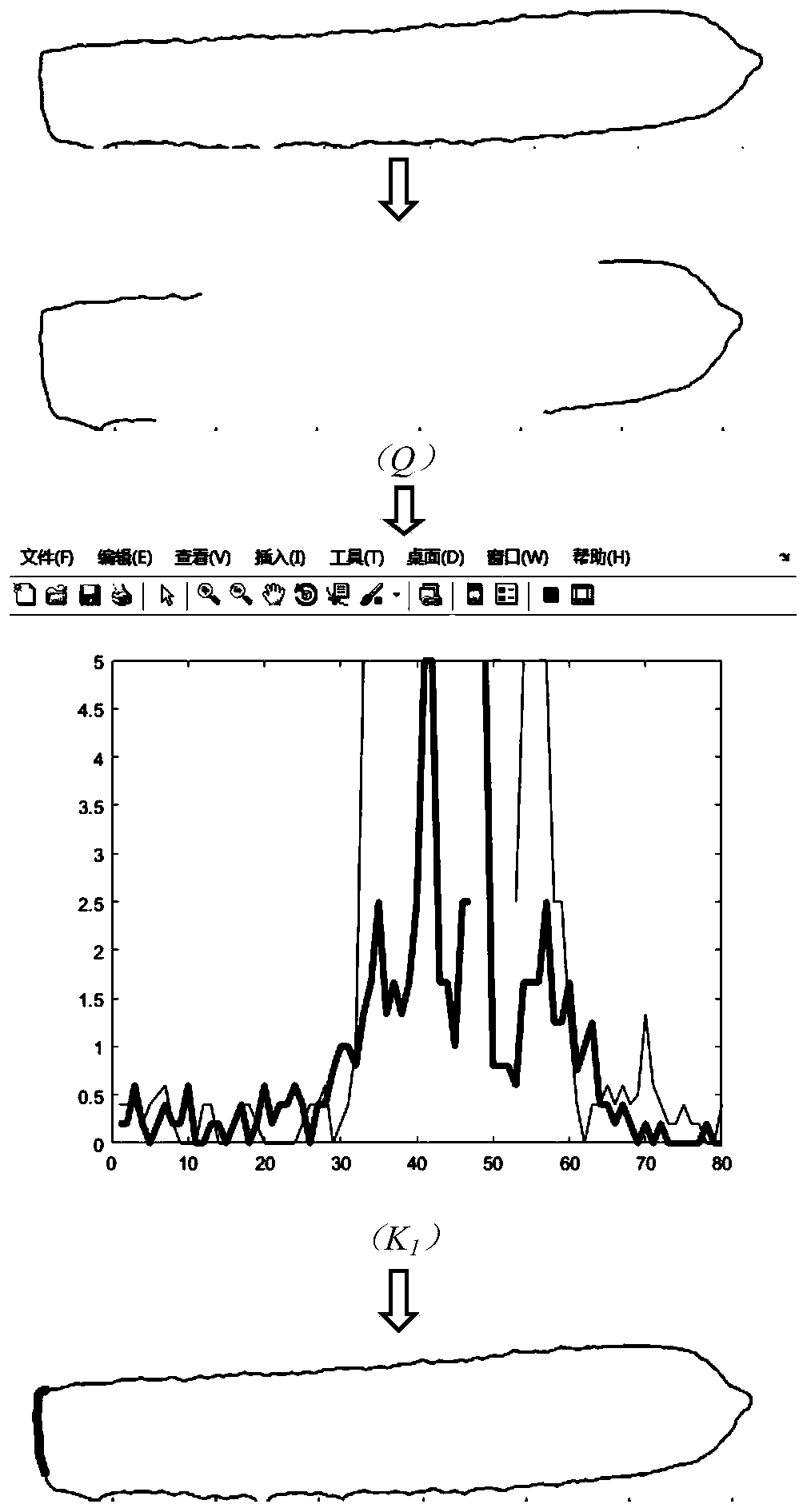

[0062] Examples, please refer to Figure 1-Figure 6 , figure 1 The main flow chart of carrot defect identification and quantification according to the present invention is given; figure 2 A flow chart of identification and quantitative detection of carrot fibrous roots in the present invention is provided; image 3 A schematic diagram showing the quantitative detection of fracture identification in the present invention; Figure 4 Schematically presents the principle diagram of the bending recognition quantification detection in the present invention; Figure 5 A schematic diagram showing the quantitative detection of crack identification in the present invention; Figure 6 It shows the principle diagram of identification and quantitative detection of carrot fibrous roots in the present invention.

[0063] First, a CCD camera is used to capture images o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Circularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com