Paint scar cleaning device of motor stator

A technology for cleaning devices and motor stators, which is applied in the manufacture of stator/rotor bodies, machine tools suitable for grinding the edge of workpieces, grinding machines, etc., which can solve the problems of long time consumption, low work efficiency, and high labor intensity, and achieve work efficiency. High efficiency, flexible use, and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

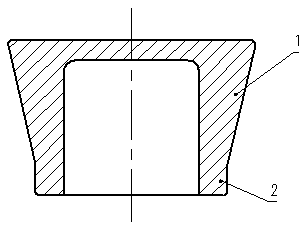

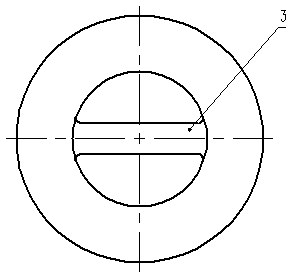

[0010] Such as figure 1 , 2 As shown, the paint brush cleaning device is a cylinder 1 with two ends open. The section of the cylinder 1 is isosceles trapezoid or straight cylinder. The surface of the cylinder 1 is provided with knurling. The cylinder 1 is rotated during use. The paint bumps on the inner surface of the stator core end can be polished by the knurling on the surface of the cylinder 1; the outer diameter of one end 2 of the cylinder 1 matches the diameter of the stator core. When in use, the end 2 of the cylinder 1 It can be put into the stator core; a handle 3 is provided on the other end of the cylinder 1, the handle 3 and the end surface of the other end 2 of the cylinder 1 are parallel to each other, and the outer diameter of the fixed handle 3 can be larger than the other end The outer diameter of the part 2 can also be equal; when in use, put the end 2 of the cylinder 1 into the stator core, hold the handle 3 to rotate the cylinder 1, and use the knurling on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com