A device for selecting biomass particles

A biomass particle and consistent technology, applied in the direction of solid separation, classification, chemical instruments and methods, etc., can solve the problem of being unable to select longer biomass particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

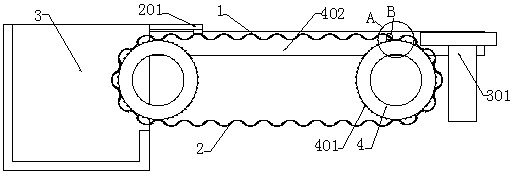

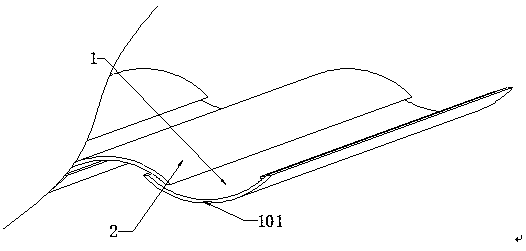

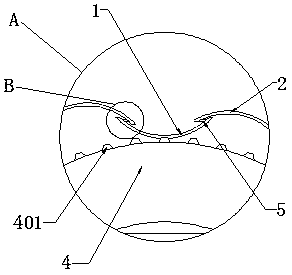

[0027] as attached figure 1 to attach Figure 7 Shown:

[0028] The present invention provides a biomass particle selection device, including: receiving tile 1, tooth groove 101, separation tile 2, scraper bar 201, biomass particle placement box 3, selection column 301, rotating shaft 302, selection block 303, base 304, rotating roller 4, tooth protrusion 401, abutment plate 402, connecting block 5 and connecting groove 501, a connecting groove 501 is provided at the center of the bottom surface of the receiving tile 1, and a separating tile 2 is provided on the top of the receiving tile 1, and the receiving tile 1 One side of the biomass particle storage box 3 is provided, the side of the biomass particle storage box 3 close to the separation tile 2 is fixed with a scraper 201, and the side of the receiving tile 1 away from the biomass particle storage box 3 is fixed with a selection column 301, the selection column 301 is provided with a rotating shaft 302 near the side o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com