Stamping die

A technology for stamping dies and die bases, which is applied in the direction of perforating tools, forming tools, manufacturing tools, etc., can solve the time-consuming and labor-intensive problems of the loading tank, and achieve the effect of improving cleaning efficiency and improving cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

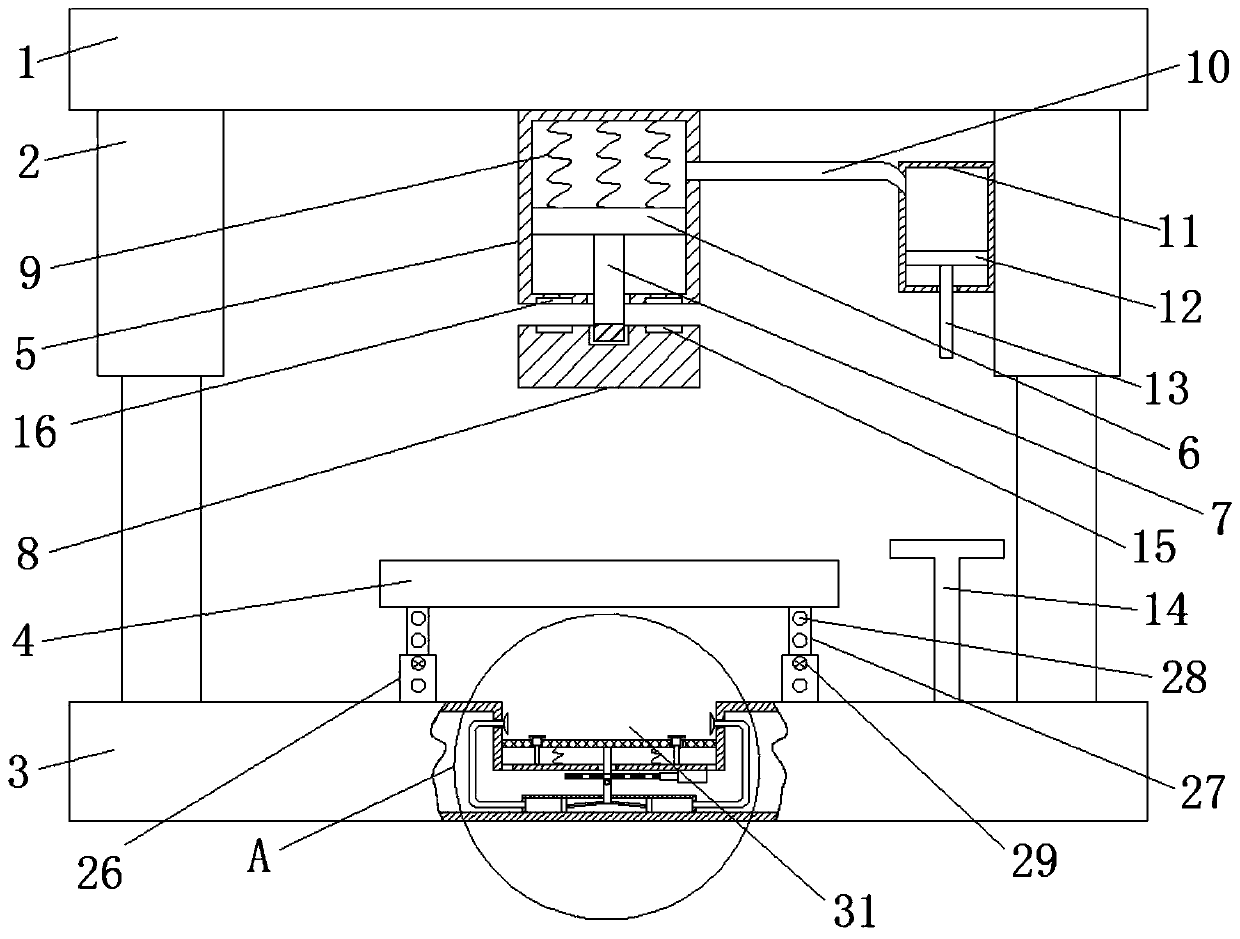

[0045] refer to Figure 1-3 , a stamping die, including an upper mold base 1, a lower mold base 3, a core plate 4 and a punch mechanism. The lower mold base 3 is connected with the upper mold base 1 through two guide columns 2 . Loading trough 32 is used to carry the workpiece that is washed away; Offer the model hole that is used for forming on the mold core plate 4 such as figure 2 As shown, and there are positioning pins on the core plate 4, which are not shown in the figure. Use positioning pins to locate the position of the workpiece. The mold core plate 4 is installed on the lower mold base 3 .

[0046] Wherein, the punch mechanism includes a sleeve one 5, a piston one 6, a push rod one 7, a movable punch 8, a sleeve two 11, a piston two 12, a push rod two 13 and a T-shaped support plate 14.

[0047] The sleeve one 5 is installed on the upper mold base 1; the piston one 6 is slidably installed inside the sleeve one 5. The upper end surface of the piston one 6 is co...

Embodiment 2

[0054] After the stamping die in Example 1 is used for a long time, the punch part is easily damaged and needs to be replaced. However, in the prior art, it is cumbersome to replace the punch and also wastes resources. For this, we must improve on this. The specific improvement plan is as follows:

[0055] refer to figure 1 and image 3 , the other end of movable punch 8 and push rod one 7 is detachably connected. There are two schemes for the detachable connection, for those skilled in the art to refer to.

[0056] Option 1: The other end of the push rod 7 is provided with an external thread. The movable punch 8 is provided with an internal thread groove corresponding to the external thread. Push rod one 7 is connected with movable punch 8 by threads such as figure 1 shown.

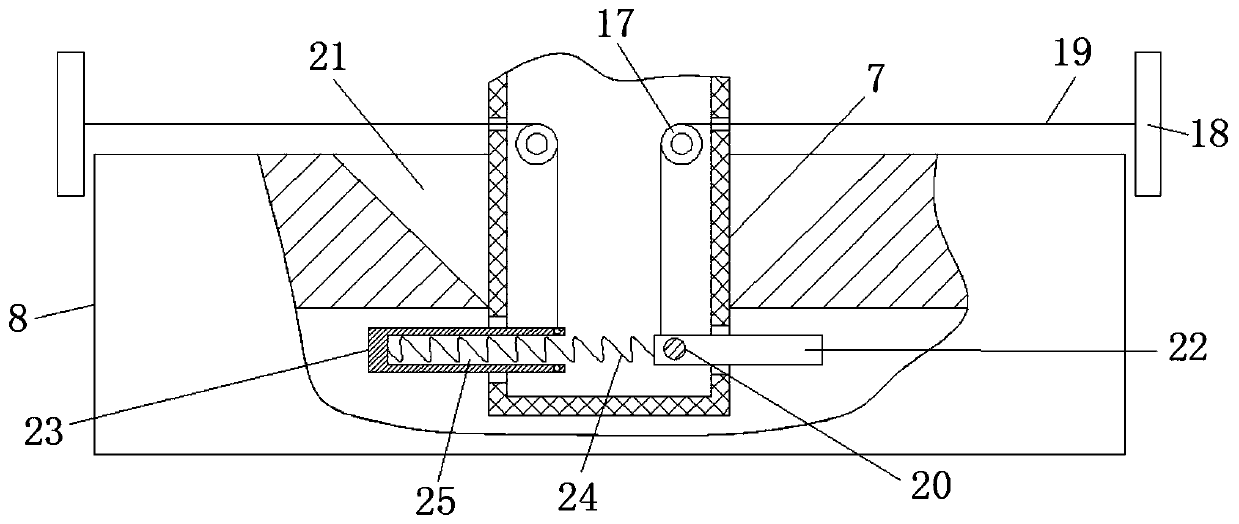

[0057] Option two: the push rod one 7 and the movable punch 8 are both hollow structures. The top of the movable punch 8 is provided with a wedge-shaped hole 21, and the movable punch 8 is provi...

Embodiment 3

[0062] When utilizing the stamping die in embodiment 1 and embodiment 2 to carry out punching, the workpiece that is punched off falls directly on the lower mold base 3 . Can cause the lubricating oil splash on the workpiece that is washed away like this, pollute the table top of lower mold base 3. It is relatively laborious to clean the table top of the lower mold base 3 . To this end, we make the following improvements:

[0063] refer to Figure 4-5 , Stamping die, comprise lower mold base 3, slide plate 32, energy storage spring 33, blocking mechanism 35, U-shaped cover 37, two sliders 38, two connecting rods 39, iron rod two 310, two infusion tubes 312, Two tent heads 313, an electric push rod 314, a moving plate 315 and a permanent magnet one 316.

[0064] Wherein, the lower mold base 3 is a hollow structure, and the lower mold base 3 is provided with a loading groove 31 . The loading trough 31 is used to collect the washed workpieces in a concentrated manner. At lea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com